Precision cycloid decelerator

A cycloid reducer, precise technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of increase in pin size, transmission power of reducer, torque and stiffness limitation, and increase in eccentricity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

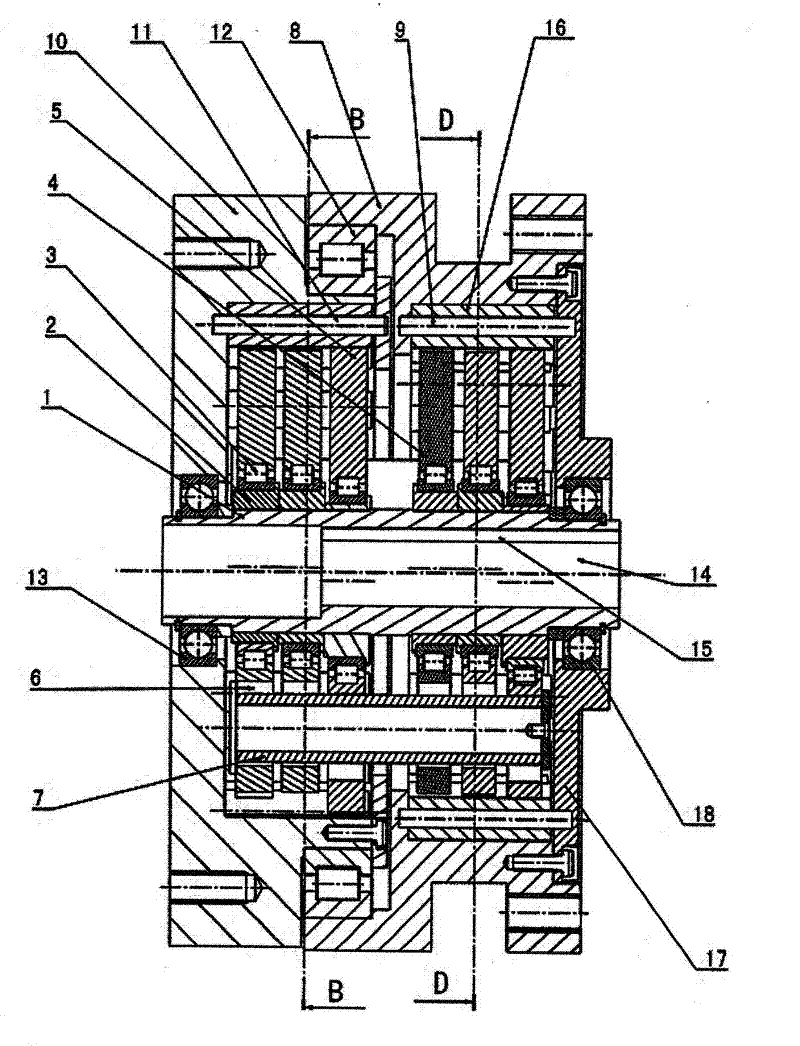

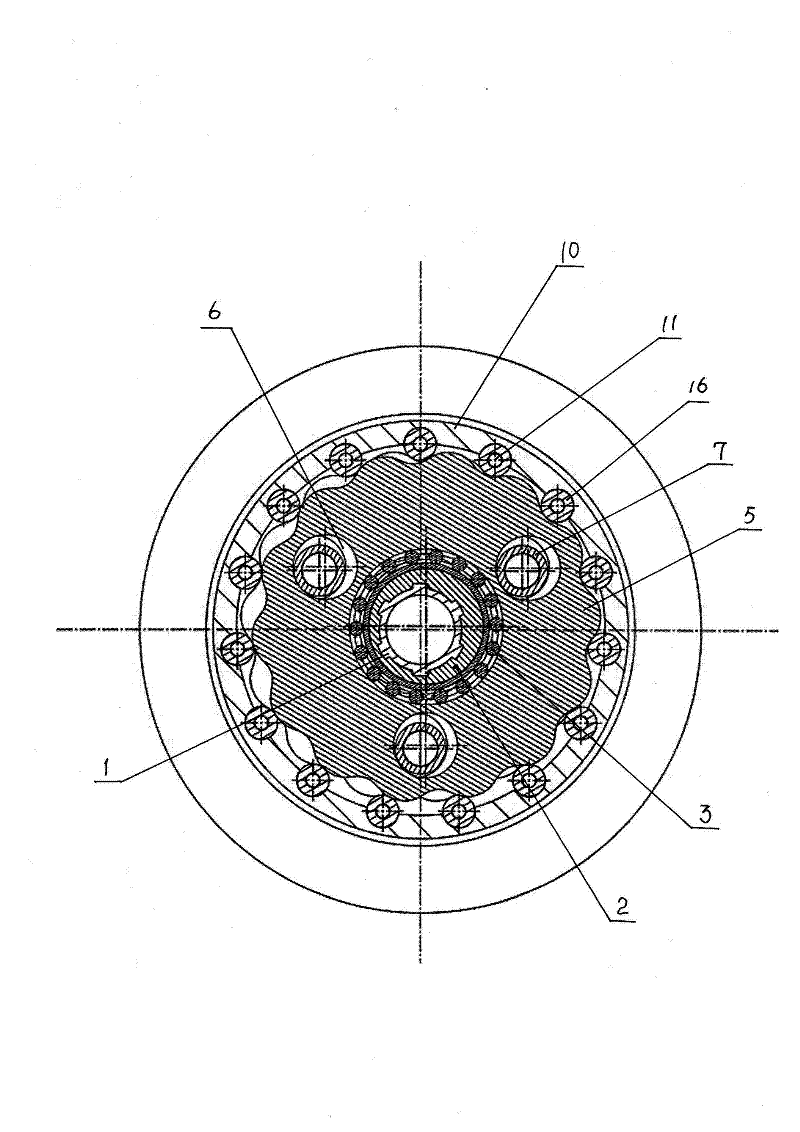

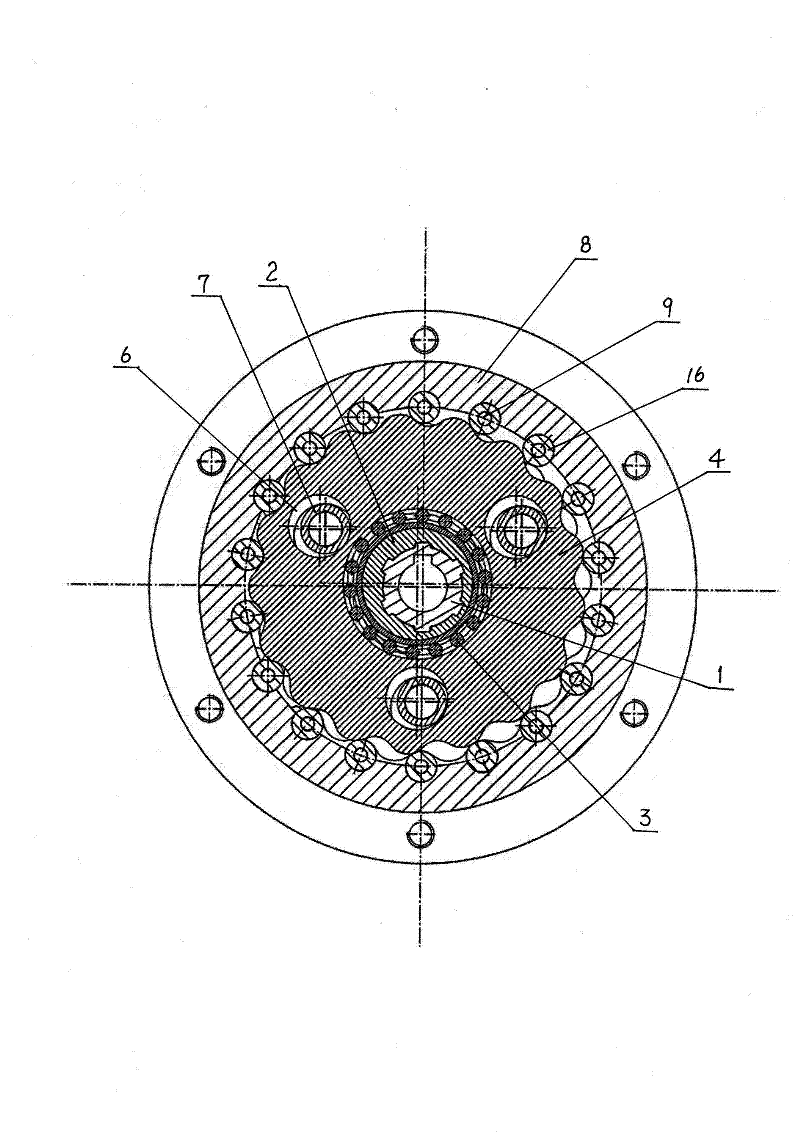

[0017] As shown in the figure, the present invention includes a rotating arm 1 and an eccentric sleeve 2 fixed outside the rotating arm 1. The rotating arm 1 adopts a splined rotating arm, which is connected with an external input shaft 14 through a key 15, which is convenient for processing and installation. The eccentric sleeve 2 is connected to the cycloidal wheel through the rotating arm bearing 3, and the cycloidal wheel is matched with the pin tooth pin fixed on the pin gear housing. The eccentric sleeve 2 fixed outside the rotating arm 1 is arranged in multiple misalignments, and each eccentric sleeve 2 The cycloidal wheel is divided into two groups: the reverse cycloidal wheel 4 and the forward cycloidal wheel 5. The reverse cycloidal wheel 4 and the forward cycloidal wheel 5 have different numbers of teeth and have a connection transmission hole 6. The reverse cycloidal wheel 4 and the forward direction The cycloid wheel 5 is connected by a connecting shaft 7 passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com