Preparation method of rhapontin

A technology of rhubarb and rhubarb, applied in the preparation of rhubarb, using supercritical extraction technology combined with membrane separation technology to prepare rhubarb, which can solve the problems of low product purity, high energy consumption, and large solvent usage, etc. problem, to achieve the effect of simple operation of process steps and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

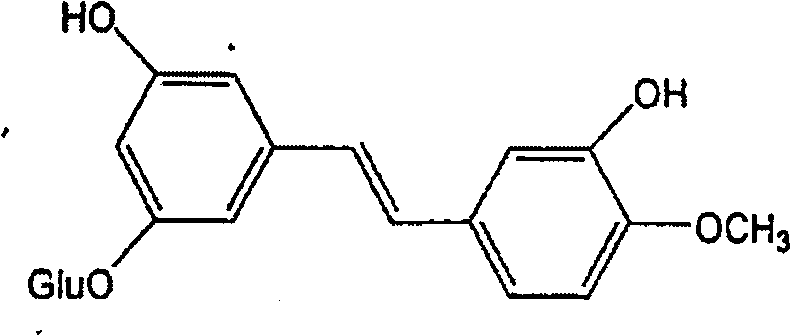

Image

Examples

Embodiment 1

[0024] Get 1kg of rhubarb rhubarb, pulverize, place in the extraction kettle, seal, set the temperature of the extraction kettle to be 45°C, the pressure to be 25MPa, the temperature of the separation kettle I to be 18°C, the pressure to be 15MPa, and the temperature of the separation kettle II to be 8°C. The pressure is 10MPa, turn on the extractor, separator and other devices to preheat the system, start the high-pressure pump, pass in 200ml of ethanol as a modifier, turn on the CO 2 Intake switch, start the compression pump, make the pressure reach the required range, keep the pressure for extraction for 1.5h, open the separation kettle I and separation kettle II, and carry out the separation operation, collect the extract, dissolve it with a sodium hydroxide solution of pH 9, and filter to remove the insoluble The solution is added to an ultrafiltration device with a pore size of 5nm for ultrafiltration. The permeate pressure is 0.5MPa. The permeate is concentrated through ...

Embodiment 2

[0026] Get 5kg of Tianshan rhubarb, pulverize, place in the extraction kettle, seal, set the temperature of the extraction kettle to be 35°C, the pressure to be 35MPa, the temperature of the separation kettle I to be 20°C, and the pressure to be 10MPa, the temperature of the separation kettle II to be 15°C, and the pressure to 6MPa, turn on the extractor, separator and other devices to preheat the system, start the high-pressure pump, feed 2.5L ethanol as a modifier, and turn on the CO 2 Intake switch, start the compression pump, make the pressure reach the required range, keep the pressure for extraction for 3 hours, open the separation kettle I and separation kettle II, carry out the separation operation, collect the extract, dissolve it with a potassium hydroxide solution of pH 11, and filter to remove the insoluble matter , the solution is added to an ultrafiltration device with a pore size of 15nm for ultrafiltration. The permeate pressure is 1MPa. The permeate is concentr...

Embodiment 3

[0028] Take 10kg of rhubarb in North China, pulverize it, put it in the extraction kettle, seal it, set the temperature of the extraction kettle to 38°C, the pressure to 28MPa, the temperature of the separation kettle I to 20°C, the pressure to 13MPa, the temperature of the separation kettle II to 12°C, and the pressure to 8MPa, turn on the extractor, separator and other devices to preheat the system, start the high-pressure pump, feed 3L ethanol as a modifier, and turn on the CO 2 Intake switch, start the compression pump, make the pressure reach the required range, keep the pressure for extraction for 2.5h, open the separation kettle I and separation kettle II, and carry out the separation operation, collect the extract, dissolve it with a sodium hydroxide solution of pH 10, and filter to remove the insoluble The solution is added to an ultrafiltration device with a pore size of 10nm for ultrafiltration. The permeate pressure is 0.8MPa. The permeate is concentrated through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com