Method for adjusting verticality of rolling mill

An adjustment method and verticality technology, applied in the direction of metal rolling, metal rolling, length measuring device, etc., can solve the problems of large cumulative error, inaccurate data, increase in manpower, material resources, and time, so as to reduce the impact and ensure Accuracy, effect of reducing export steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

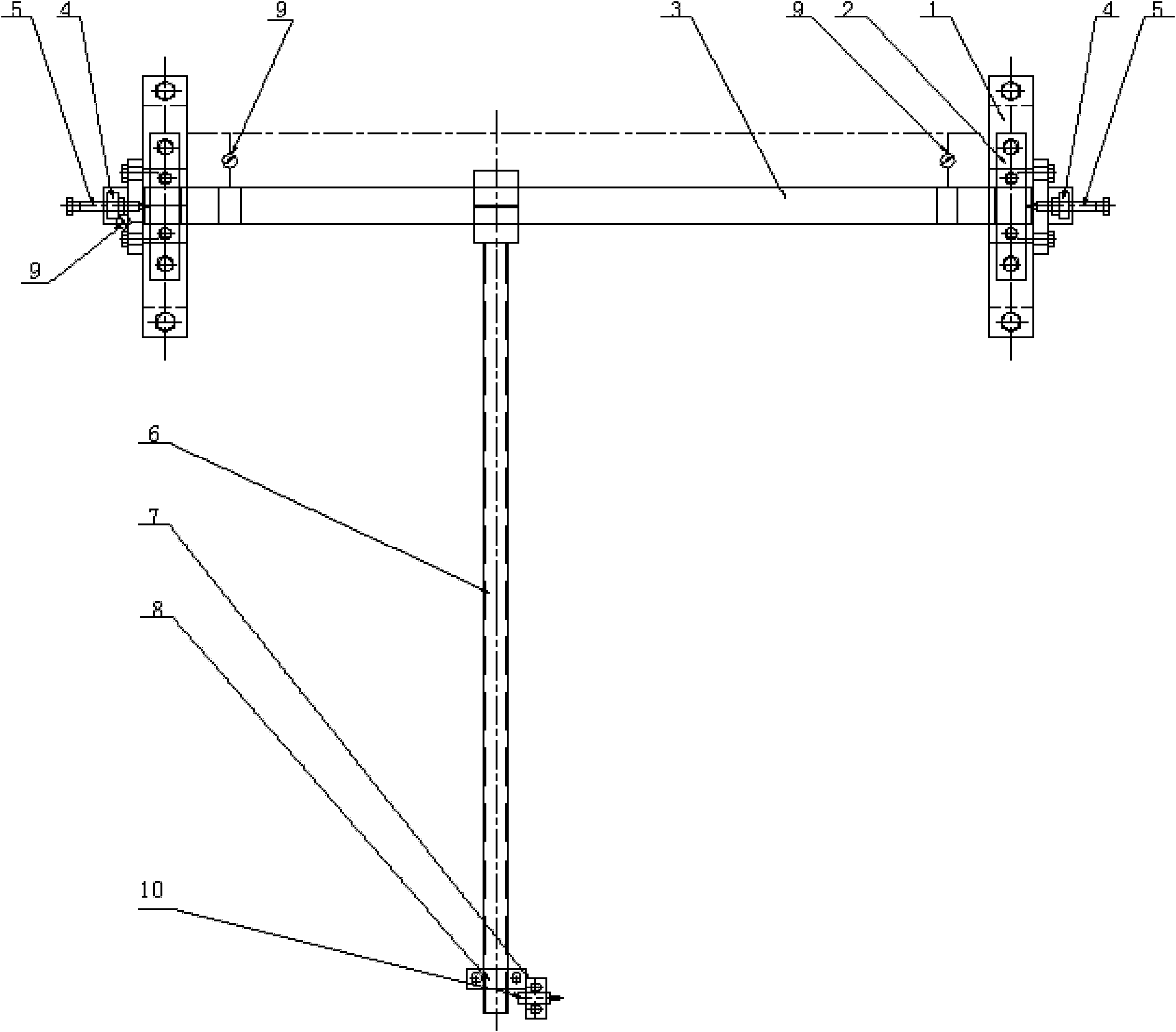

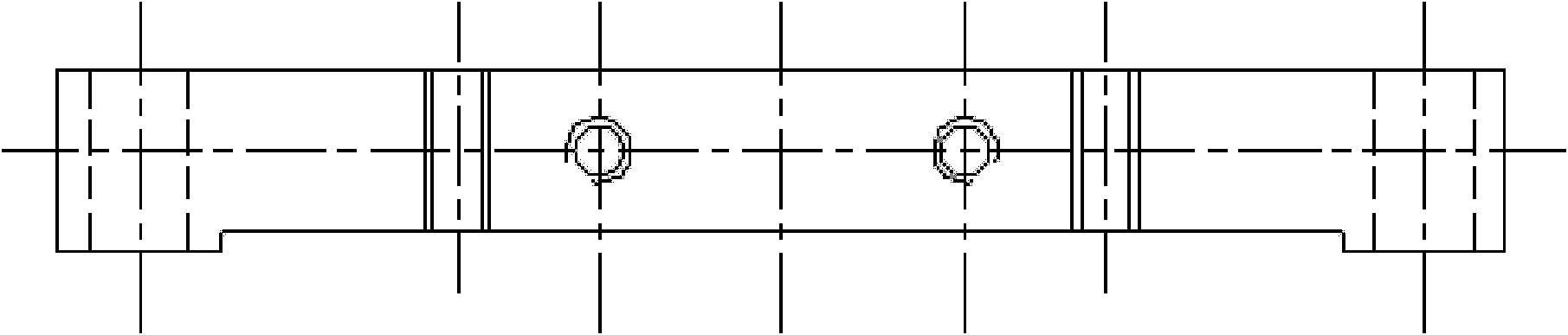

[0036] The verticality measurement between the rolling mill floor and the rolling line (such as Figure 15 ):

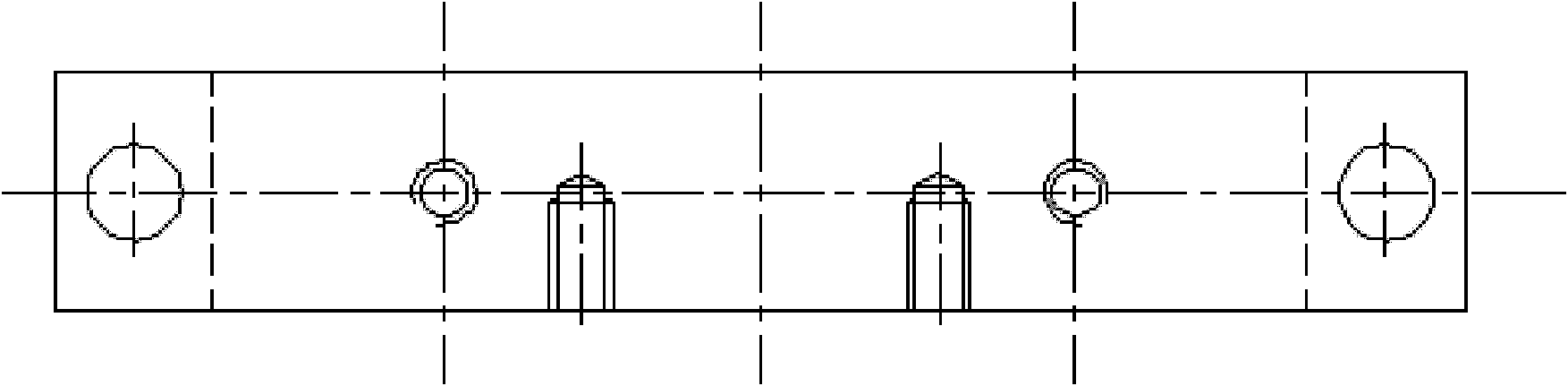

[0037] Fix the second base of the pendulum tool 12 on the bottom plate 13 of the rolling mill stand, fix the two dial gauges 9 on the bottom plate 13 of the rolling mill stand through the magnetic base, and the detection rod of the dial indicator 9 measures the radial surface of the shaft , rotate the rocker arm 6 of the pendulum tool and adjust the sliding bearing 2 at the first base so that the reading of the two dial indicator 9 remains basically unchanged, and then place the dial indicator 9 on the shaft end, and the detection rod of the dial indicator 9 measures the shaft end surface , detect the axial displacement of the shaft during the pendulum process, install a micrometer 10 in the fixture 8, listen to the sound with earphones, rotate the rocker arm 6 of the pendulum tool 12 to two predetermined positions on the piano line, and read the micrometer 10 and T...

Embodiment 2

[0039] Perpendicularity measurement between arch base window and rolling line (such as Figure 18 )

[0040] Utilize the jack 16 and the support 17 to fix the steel level ruler 14 on the vertical plane of the two archways 15 of the rolling mill stand, measure with a square level to keep the level ruler 14 level, and fix the first base of the pendulum tool 12 on the level ruler 14, and then measure the perpendicularity between the benchmark window of the rolling mill frame archway and the rolling line according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com