Wet-type magnetic separation method of magnetite

A magnetite and wet technology, applied in the field of magnetite wet magnetic separation, can solve the problems of high power consumption and steel consumption, and high production cost, and achieve the effect of reducing steel consumption and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

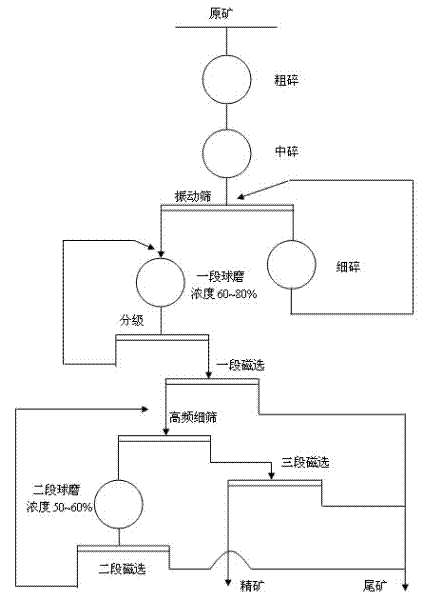

[0022] Embodiment 1: a kind of method for magnetite wet type magnetic separation, comprises the steps:

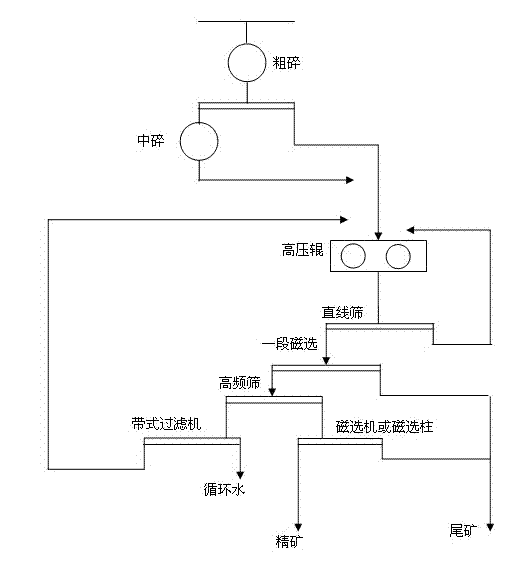

[0023] A. Send the raw magnet ore to the crusher for coarse crushing, and then send it to the vibrating screen for screening. The sieve hole is controlled to 35mm. crushed;

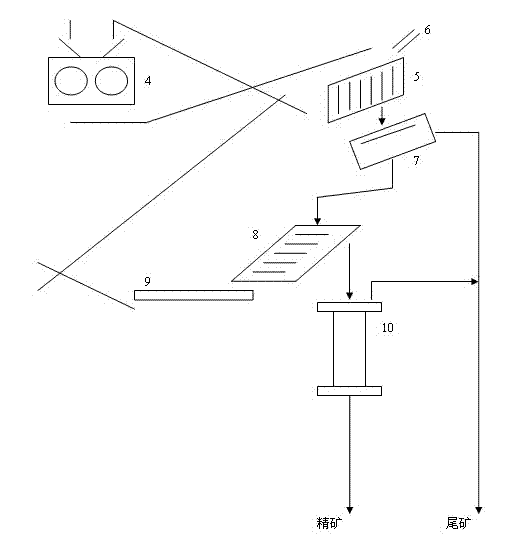

[0024] B, the finely crushed ore in step A is sent to a wet linear vibrating screen for screening, the oversize is returned to the high pressure roller mill for fine crushing, the undersize is subjected to wet magnetic separation, and the magnetic field strength is controlled to 180mT;

[0025] C. Send the ore after wet magnetic separation in step B into a high-frequency vibrating fine sieve, and control the sieve hole size to 0.2mm. Enter the magnetic separator for magnetic separation to obtain a concentrate product with a grade of 66.5%.

[0026] In the step A, the magnet raw ore is roughly crushed to 200mm by a gyratory crusher.

[0027] In the step A, a standard cone crusher is used for intermed...

Embodiment 2

[0030] Embodiment 2: a kind of method for magnetite wet type magnetic separation, comprises the steps:

[0031] A. Send the raw magnet ore to the crusher for coarse crushing, and then send it to the vibrating screen for screening. The sieve hole is controlled to 55mm. crushed;

[0032] B, the finely crushed ore in step A is sent to a wet linear vibrating screen for screening, the oversize is returned to the high pressure roller mill for fine crushing, the undersize is subjected to wet magnetic separation, and the magnetic field strength is controlled to 180mT;

[0033] C. Send the ore after wet magnetic separation in step B into a high-frequency vibrating fine screen, and control the screen hole size to 0.12mm. Enter the magnetic separation column for magnetic separation to obtain a concentrate product with a grade of 65%.

[0034] In the step A, the raw magnet ore is roughly crushed to a size of 150mm by a jaw crusher.

[0035] In the step A, a standard cone crusher is use...

Embodiment 3

[0038] Embodiment 3: a kind of method for magnetite wet type magnetic separation, comprises the steps:

[0039] A. Send the raw magnet ore to the crusher for coarse crushing, and then send it to the vibrating screen for screening. The sieve hole is controlled to 60mm. crushed;

[0040] B, the finely crushed ore in step A is sent to a wet linear vibrating screen for screening, the oversize is returned to the high pressure roller mill for fine crushing, the undersize is subjected to wet magnetic separation, and the magnetic field strength is controlled to 180mT;

[0041] C. Send the ore after wet magnetic separation in step B into a high-frequency vibrating fine sieve, and control the sieve hole size to 0.5mm. Enter magnetic separator magnetic separation, obtain the concentrate product of grade 65%.

[0042] In the step A, the raw magnet ore is roughly crushed to a size of 180mm by a jaw crusher.

[0043] In the step A, a standard cone crusher is used for intermediate crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com