Lubricant circuit

A lubricant and lubricant pump technology, applied in the direction of pressure lubricant, lubrication pump, control lubricant pressure, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

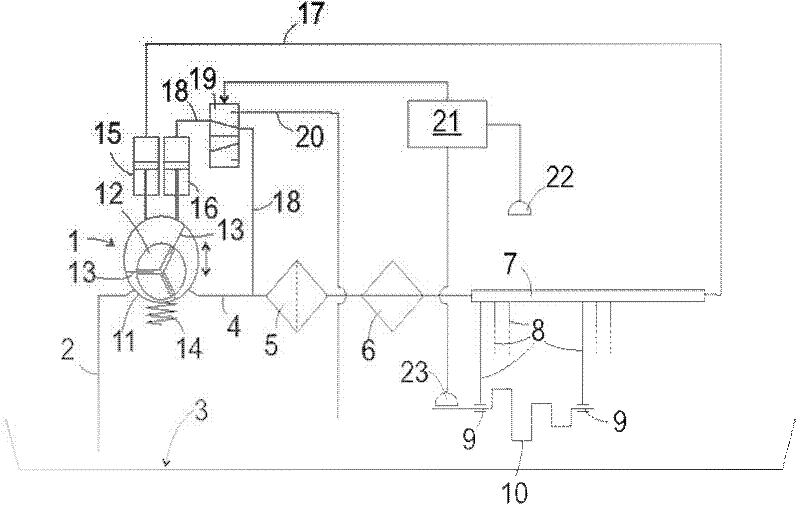

[0023] figure 1 is a schematic diagram of the lubricating oil circuit in an automobile engine. The vane pump 1 is connected with the oil pan 3 through the oil inlet pipe 2 . The distributor connected to the pressure side of the vane pump 1 includes an input line 4 and an oil passage 7, and a lubricating oil filter 5 and a lubricating oil cooler 6 are connected in series on this input line 4. From this oil Branched off from the duct 7 are branch lines 8 connected to different lubrication points 9 of the engine, for example the bearings of the crankshaft 10 . The lubricating oil flows unguided from the lubricating points 9 back into the oil sump 3 .

[0024] The vane pump 1 has, in a manner known per se, a housing 11 with a cylindrical cavity, in which a rotor 12 is arranged with a plurality of vanes 13 which are connected to the housing 11 via positioning rings. The inner surfaces of the cavity remain in contact and divide the cavity into multiple small chambers. The rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com