Catalyst components for olefin polymerization reaction, and catalyst thereof

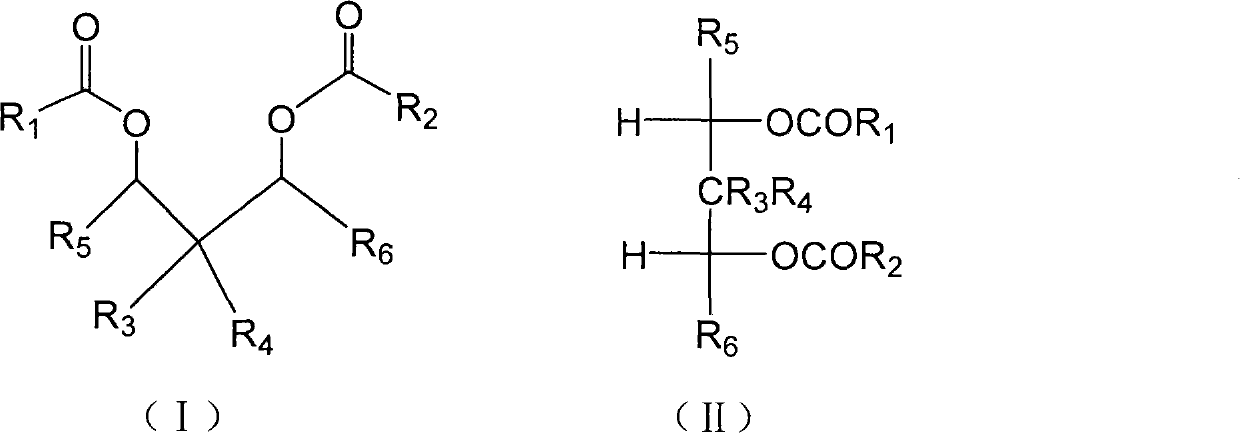

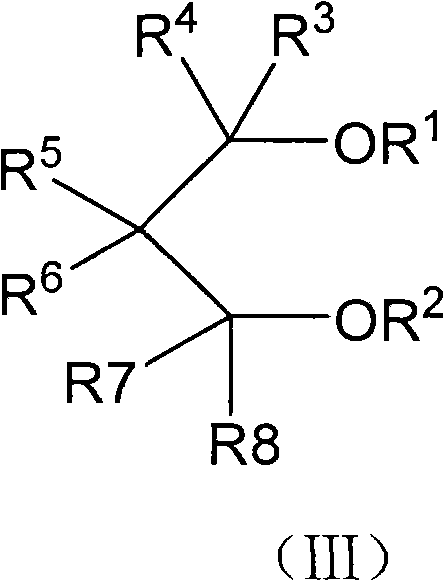

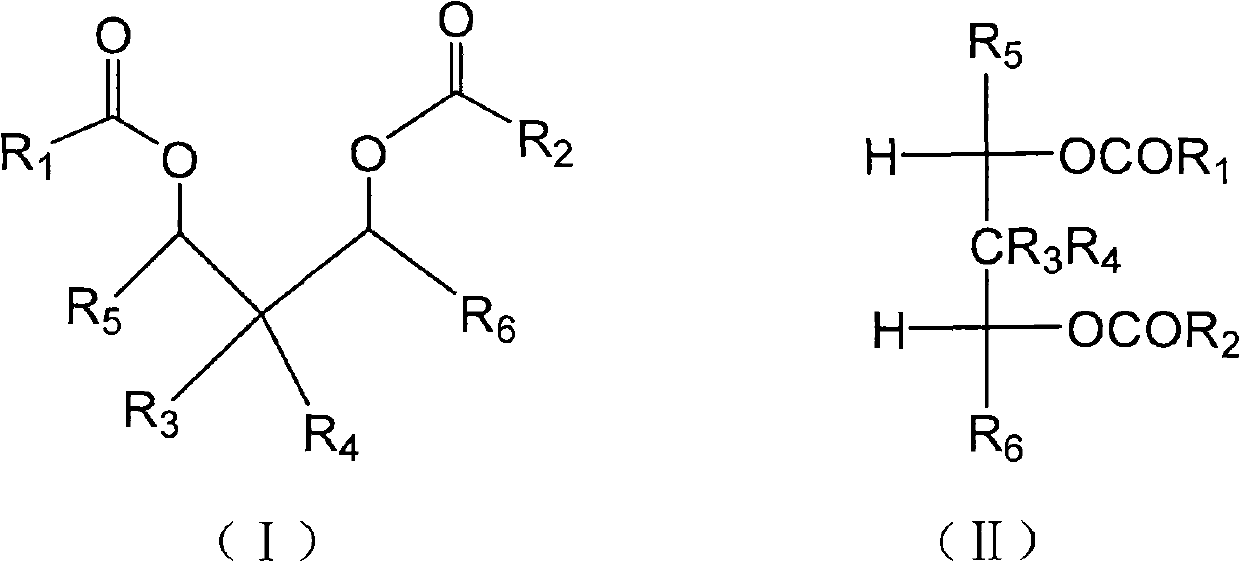

A technology for olefin polymerization and catalysts, which is applied in the field of catalyst components and catalysts for olefin polymerization reactions, and can solve the problems of insufficient isotactic index of polymers and unsatisfactory catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] 2. Preparation of solid catalyst components

[0073] Preparation method A of solid catalyst component

[0074] Under nitrogen protection, add 4.8g of anhydrous magnesium chloride, 19.5g of isooctyl alcohol and 19.5g of decane solvent into a 500ml reactor equipped with a stirrer, heat to 130°C, react for 1.5 hours until magnesium chloride is completely dissolved, and add 1.1g Phthalic anhydride, continue to react at 130°C for 1 hour to obtain an alcoholate; cool the alcoholate to room temperature.

[0075] Under nitrogen protection, add the above alcoholate dropwise to 120ml of titanium tetrachloride solution precooled to -22°C, slowly raise the temperature to 100°C, add 10mmol of glycol ester compound, raise the temperature to 110°C for 2 hours, Filtrate while hot, add 120 ml of titanium tetrachloride, rise to 110 ° C for 1 hour, filter, wash the solid particles with anhydrous hexane 4 times, and dry to obtain a solid catalyst.

[0076] Preparation method B of solid c...

Embodiment 9

[0093] Embodiment 9: with embodiment 4, just toluene 60ml, TiCl 4 40ml, change the temperature to 110°C when treating the solid, and add toluene and TiCl for the first time 4 When adding 0.2mmol of di-n-butyl phthalate, followed by three times of toluene 60ml, TiCl 4 40ml, treated at 110°C for 0.5 hours, the obtained catalyst contained 10.9% of 3,5-heptanediol dibenzoate, of which the meso form accounted for 97.9%, contained 0.9% of dibutyl phthalate, and the catalyst activity was 68.6 kgPP / gcat, the isotactic index of the polymer is 98.8%.

[0094] Under the condition of hydrogenation of 9.6L, the melt index of the obtained polymer was 59.6g / 10min, and the isotactic index was 95.8%.

Embodiment 10

[0095] Embodiment 10: with embodiment 6, just toluene 60ml, TiCl 4 40ml, change the temperature to 110°C when treating the solid, and add toluene and TiCl for the first time 4 When adding 0.4mmol of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane, the resulting catalyst contains 12.1% of 4-ethyl-3,5-heptanediol dibenzoate, Among them, the meso form accounts for 96.9%, contains 2.8% of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane, the catalyst activity is 69.1kgPP / gcat, and the polymer isotactic index is 98.9%. .

[0096] Under the condition of hydrogenation of 9.6 L, the melt index of the obtained polymer was 71.5 g / 10 min, and the isotactic index was 95.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com