Vibrating screen plate tower for continuous production of liquid-liquid-liquid three-phase extraction

A sieve tray column, three-phase technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of low multi-component solute separation coefficient, limited large-scale application, unfavorable extraction process, etc., to reduce equipment complexity and operation. Convenience, reduced complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

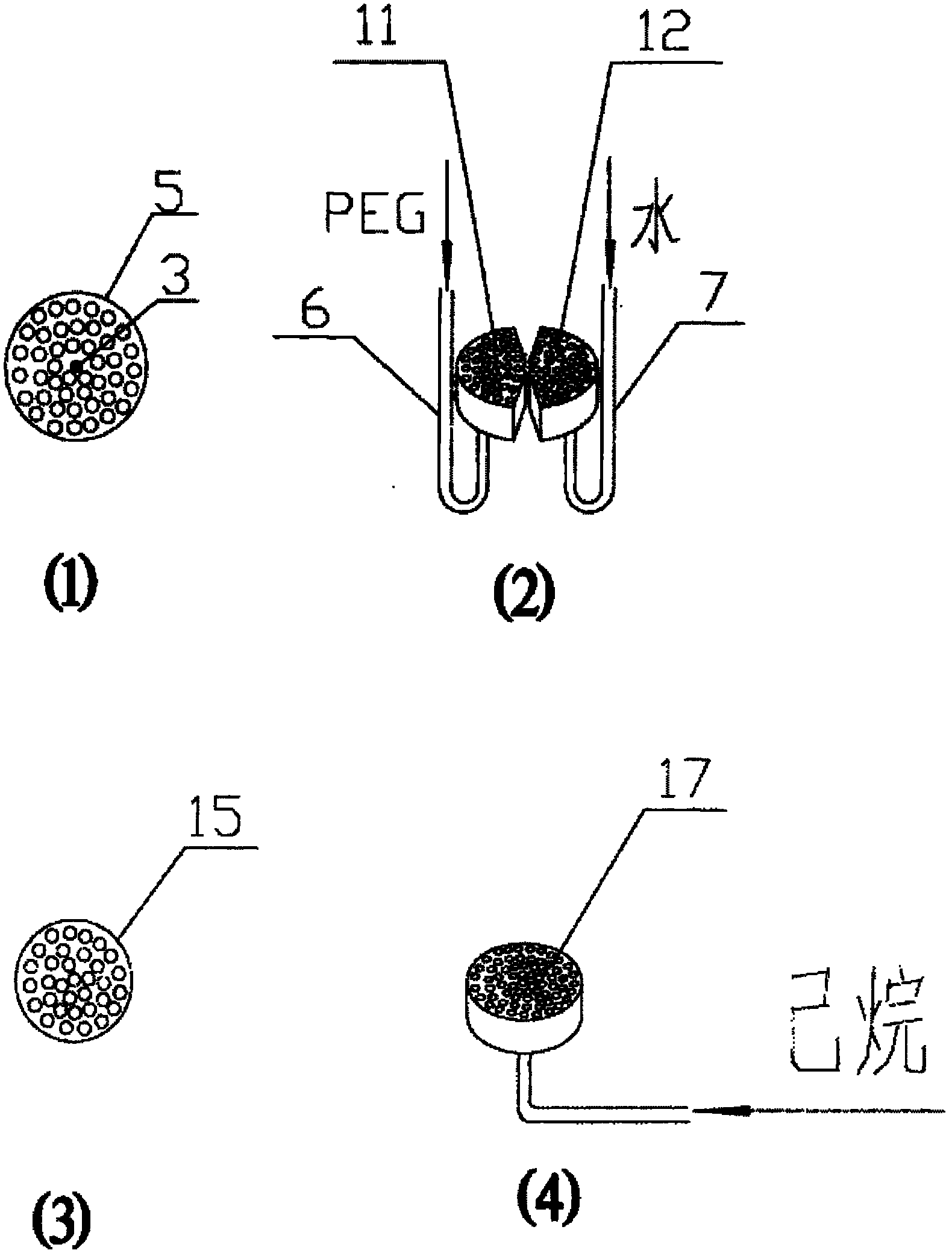

[0058] Please refer to Figure 1 to Figure 3 . The vibrating sieve plate column for continuous production of liquid-liquid-liquid three-phase extraction includes: eccentric wheel 1, connecting rod 2, main shaft 3, slider 4, tower top sieve plate 5, PEG phase conduit 6, water phase conduit 7, Heavy phase guide cylinder 8, light phase clarification outer tank 9, heavy phase mixing chamber 10, PEG distributor 11, water phase distributor 12, sealing ring 13, conical liquid baffle 14, middle sieve plate 15, columnar tower body 16. Light phase distributor 17, PEG phase outlet 18, baffle plate 19, tower bottom clarification tank 20, water phase outlet 21, metering pump 22, water phase storage tank 23, light phase storage tank 24, support frame 25, PEG phase storage tank 26 and light phase outlet 27;

[0059] A cylindrical tower body comprises a light phase clarification outer tank 9 connected at the top of the cylindrical tower body 16, a tower bottom clarification tank 20 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com