Image sensor and manufacturing method thereof

A technology of image sensor and photosensitive unit, which is applied in the field of CMOS image processing, can solve problems such as optical crosstalk, and achieve the effect of avoiding optical crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

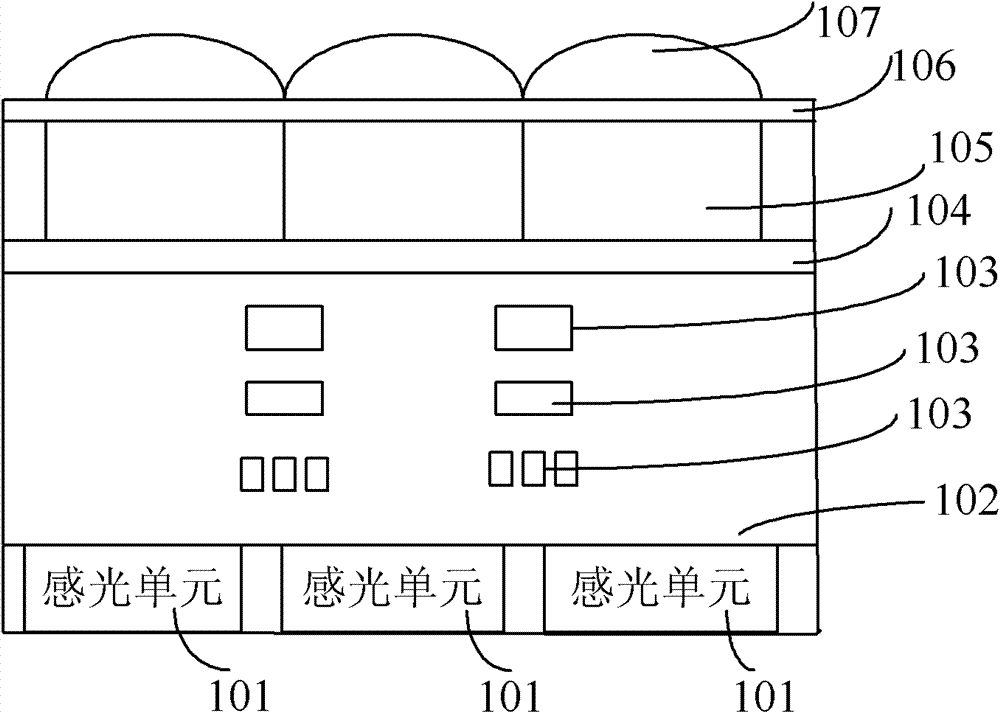

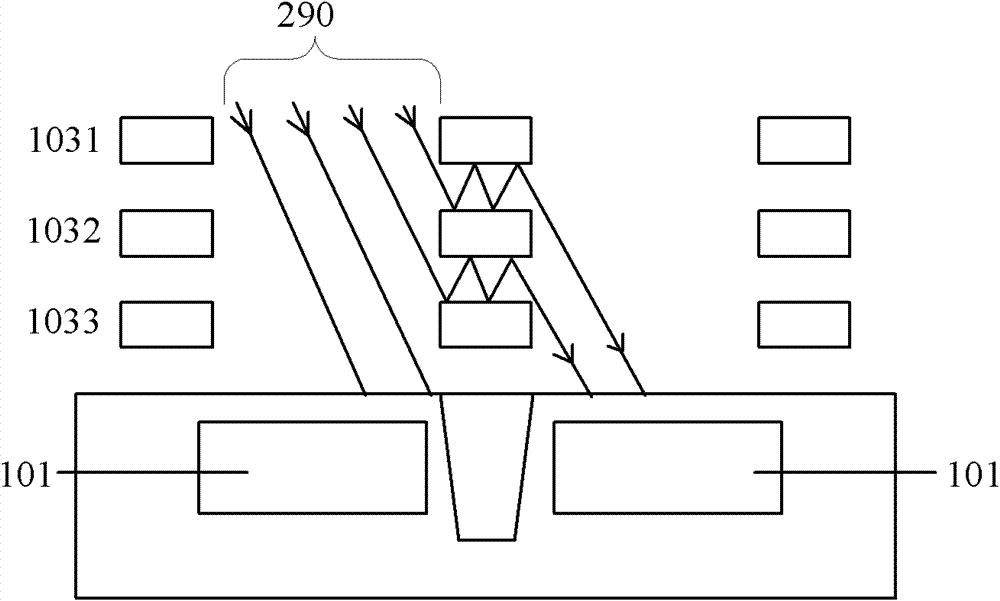

[0026] The inventors of the present invention found that in the existing image sensor, when the incident light is incident at a certain oblique angle, part of it reaches the photosensitive unit through the transparent interlayer dielectric layer, and the other part is irradiated on the metal layer and reflected. Since the position between the metal layers not connected by the conductive plugs is filled with a transparent interlayer dielectric layer, the incident light irradiated at this position is repeatedly reflected by the metal layer and finally enters other photosensitive units (usually adjacent photosensitive units). unit), forming optical crosstalk, which seriously affects the image display quality of the image sensor.

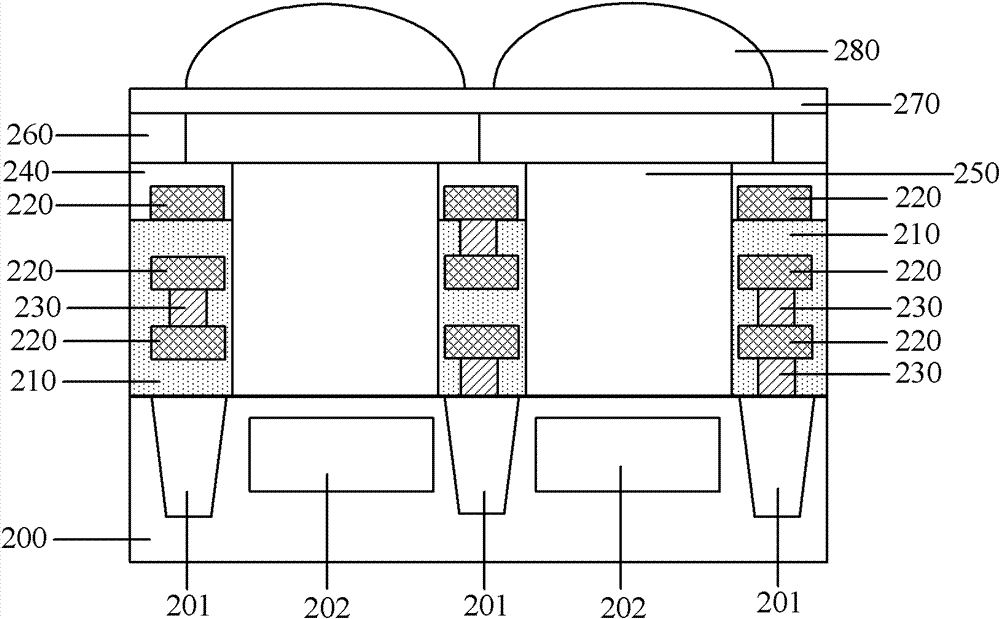

[0027] In view of the above-mentioned problems, the inventor, through research and analysis, proposes an image sensor, comprising: a semiconductor substrate, a pixel array is formed in the semiconductor substrate, the pixels include photosensitive units,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com