Steam and water separation device for steam dome

A technology of water vapor separation and steam drum, which is applied in the direction of steam separation device, etc. It can solve the problems of not designing the steam water separation device, affecting the separation purity of gas and water, and affecting the life of the boiler, so as to meet the reliability and user needs and avoid circulation. The effect of excessive resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

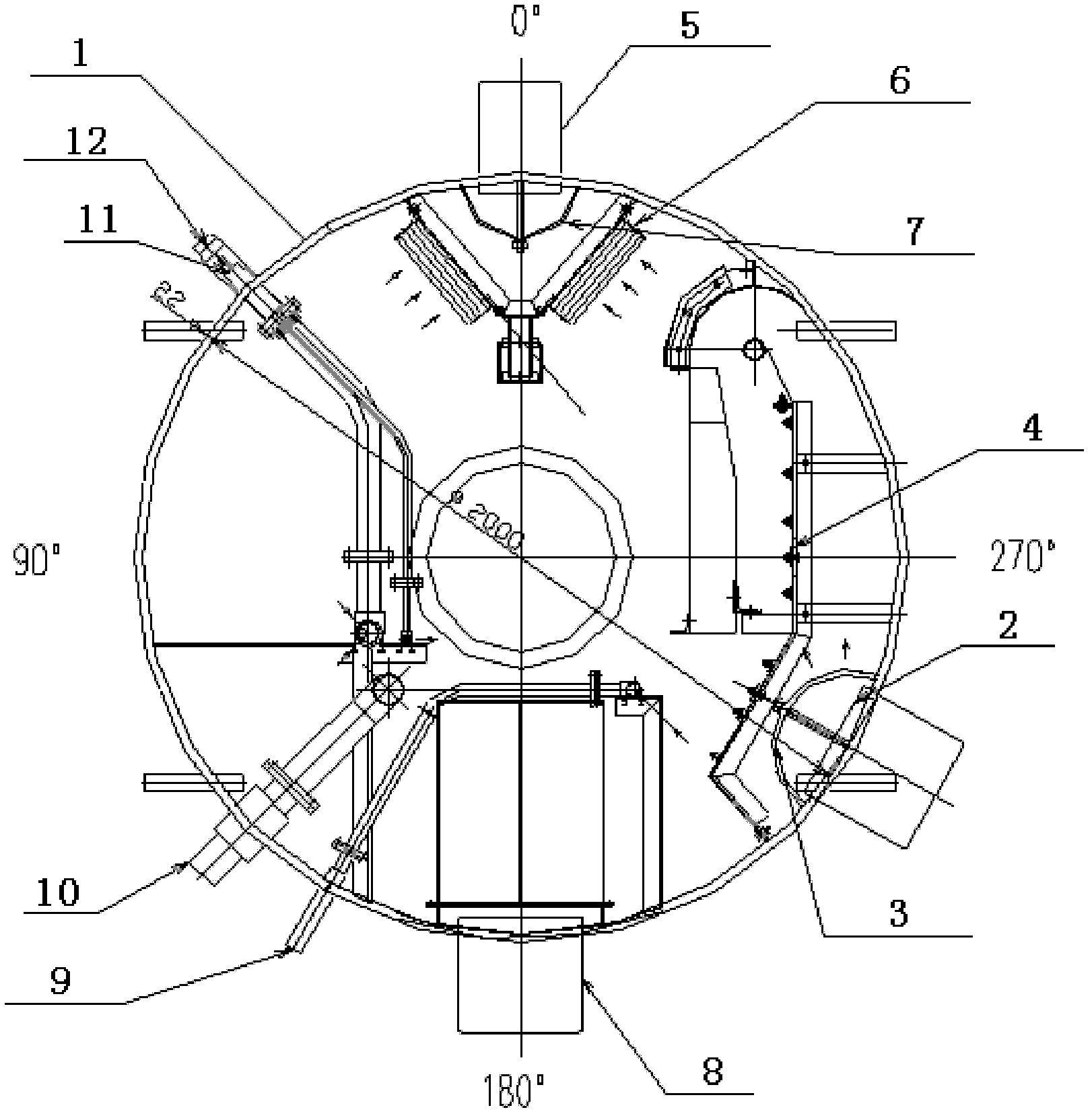

[0014] see figure 1 It can be seen that the water vapor separation device is installed in the steam drum of the waste heat boiler at the kiln head of the cement kiln to dehumidify the gas output from the steam drum. The pipe 2 is arranged on the top of the steam drum body 1 to output steam upwards, the steam outlet pipe 5, and the water supply pipe 10 extending into the steam drum, the continuous sewage pipe 9, the dosing pipe 11 and the water surface sewage pipe 12.

[0015] The water-steam separation device of the present invention mainly adopts the mode of two separations, wherein the first separation is arranged at the mouth of the inner rising pipe 2 of the steam-water mixture input on the steam drum body, and the secondary separation device is arranged at the steam drum body 1 to output the steam of the gas. At the mouth of the outlet pipe 3, such a combination can achieve a better separation effect.

[0016] The primary separation device includes an arc-shaped buffer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com