Extrusion system

A technology of extrusion wheels and mold bases, which is applied in the direction of metal extrusion dies, etc., can solve the problems of long billet runners, huge equipment, and high energy consumption, and achieve the goals of avoiding depressions and cracks, improving product quality, and shortening runners Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

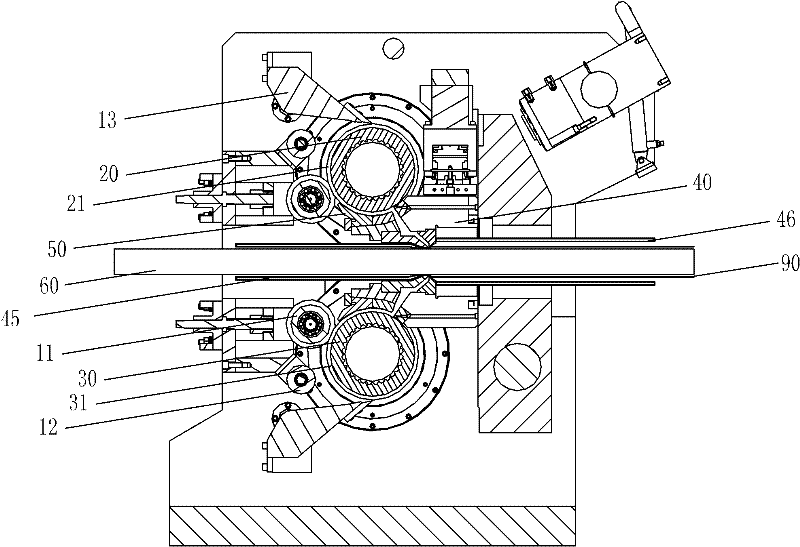

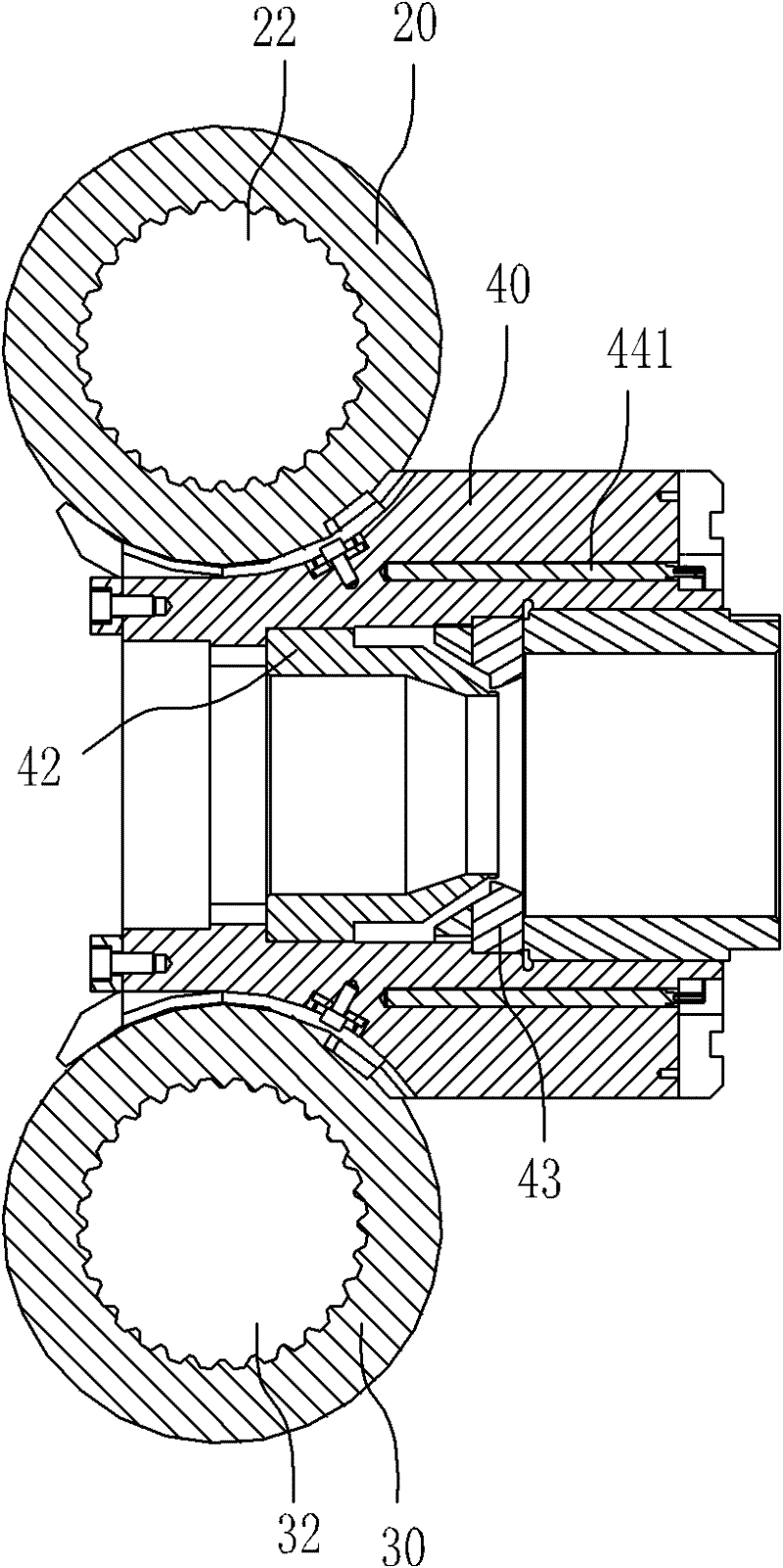

[0020] Extrusion system comprises frame 10, and frame 10 is archway shape, is provided with two extruding wheels 20,30 that rotating shafts are parallel to each other on frame 10, as the preferred scheme of the present invention, selects extruding wheels 20,30 to be arranged as The structure arranged in parallel above and below is also described in the following description as the structure arranged in parallel above and below.

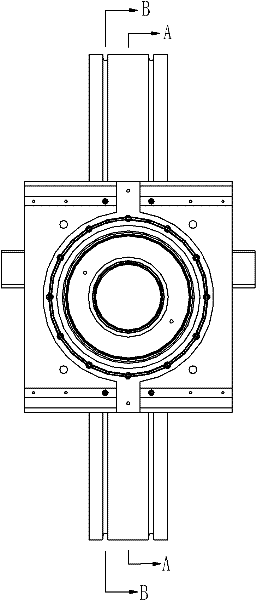

[0021] Such as figure 1 , Figure 5 As shown, the rotating shafts 22, 32 of the extrusion wheels 20, 30 are arranged in parallel up and down, the direction of rotation of the extrusion wheels 20, 30 is opposite, and the rims are respectively provided with at least one extrusion wheel groove 21, 31 in the circumferential direction, The extrusion wheel grooves 21, 31 are respectively provided with a guide seat 50 matched therewith, and the guide se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com