Mud removing device for fully-submerged rotary disk filter

A rotary disc filter, submerged technology, applied in the direction of mobile filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of poor mud suction efficiency, etc., to ensure suction, significant economy, avoid suction loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

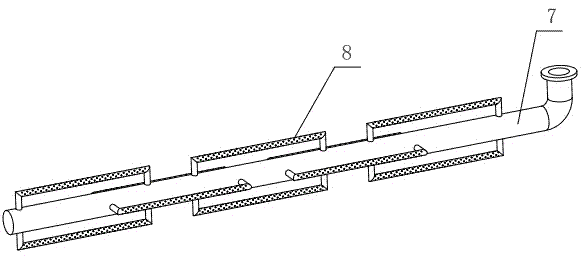

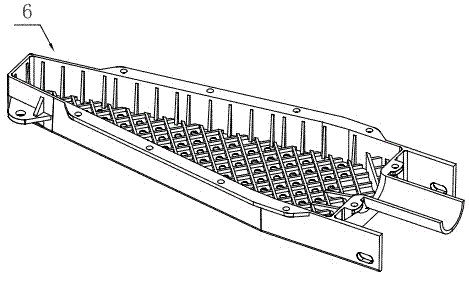

[0020] Such as figure 2 , image 3 and Figure 4 As shown, the desilting device of the fully submerged rotary disc filter of the present invention includes an air ventilation device 5 and a mud suction device 6, and the main pipe 7 of the air ventilation device 5 is fixed at the central axis of the central drum 2, and the main pipe 7 of the main pipe 7 The input end is connected to the external air pump, and the main pipe 7 is provided with a number of evenly distributed branch pipes 8, which are symmetrical multiple groups, arranged on the main pipe 7 in a cross-staggered form, and the air holes are densely distributed on the branch pipes 8; the side wall of the dredger 6 Several mud suction holes 9 are arranged on the top, and the outer mouth of the mud suction hole 9 is an inverted cone; see Figure 5 , The mud suction device 6 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com