Sucking disc structure

A technology of suction cups and components, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of simultaneous suction of liquid crystal screen LCD substrate and flexible printed circuit board FPC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

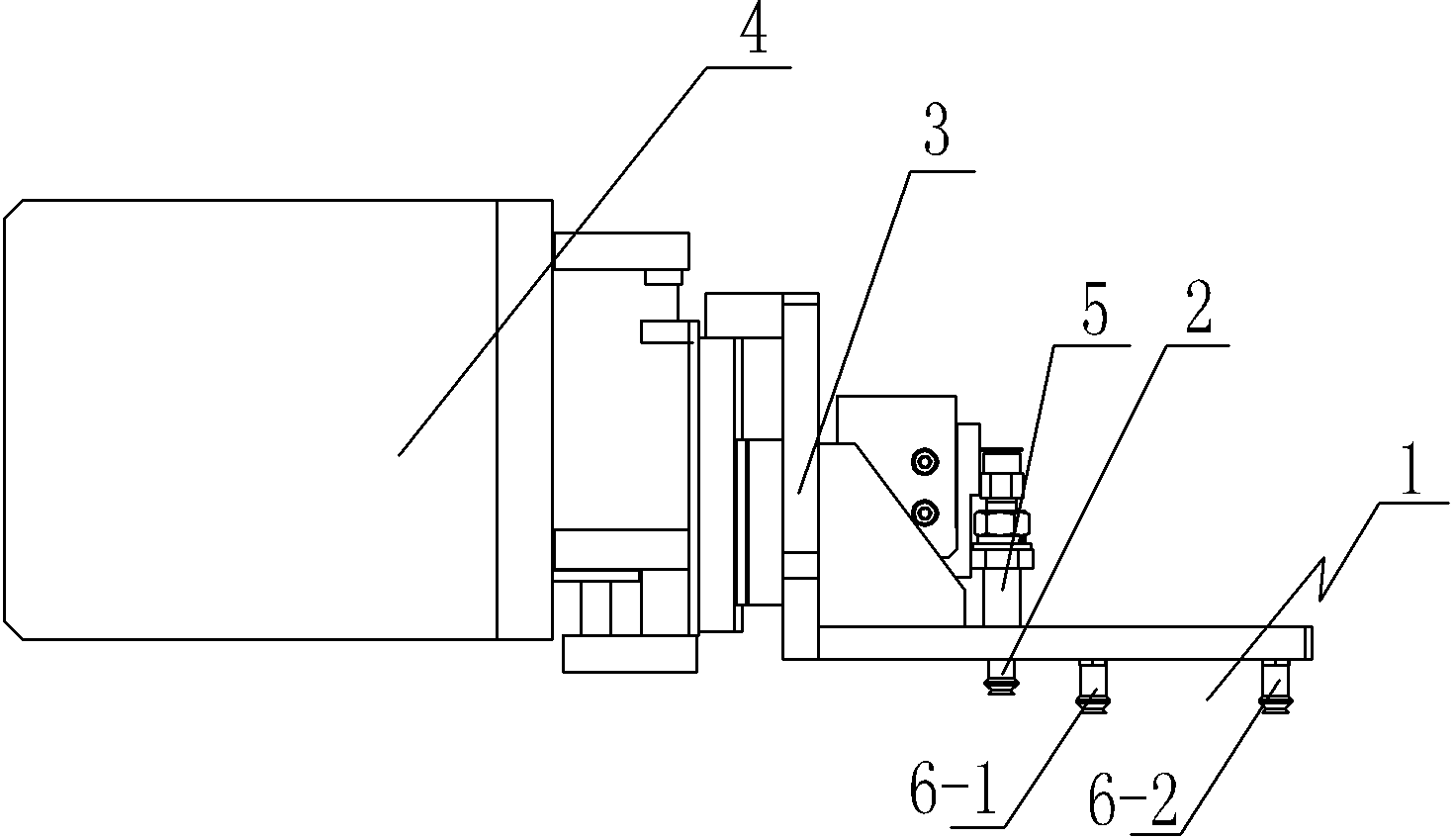

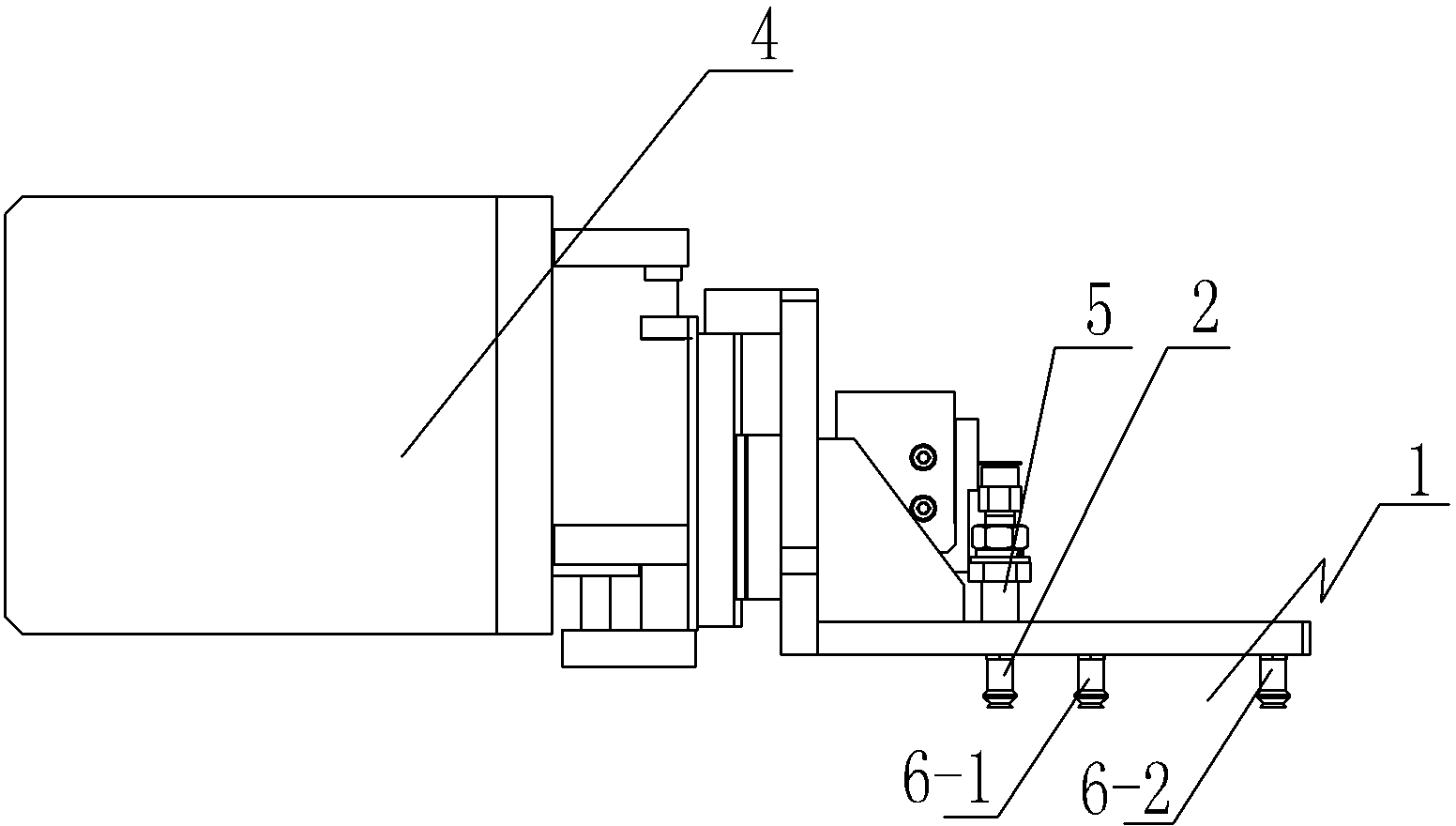

[0009] See figure 1 , figure 2 , a suction cup structure, which includes a graded first suction cup assembly 1 and a second suction cup assembly 2, the first suction cup assembly 1 is connected to the drive mechanism 4 through a support frame 3, and the second suction cup assembly 2 is movably arranged on the support frame 3 through a cylinder 5 Above, the second suction cup assembly 2 is connected to the cylinder 5, and the first suction cup assembly 2 includes double-headed suction cups 6-1, 6-2.

[0010] combine figure 1 , figure 2 To illustrate the working principle of the sucker structure of the present invention:

[0011] The driving mechanism 4 drives the support frame 3 to descend, and the graded first suction cup assembly 1 and the second suction cup assembly 2 descend. When the first suction cup assembly 1 has touched the LCD substrate of the liquid crystal screen, the second suction cup assembly 2 is driven by the cylinder 5 to descend , when the second sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com