Manipulator clamping linking wire clamp special for high voltage electriferous work

A high-voltage live, manipulator technology, used in manipulators, program-controlled manipulators, chucks, etc., to facilitate clamping, improve work safety, and avoid direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

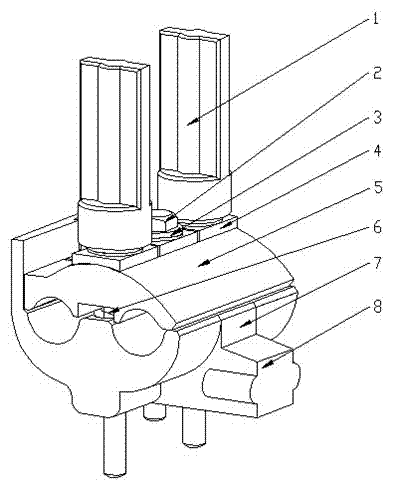

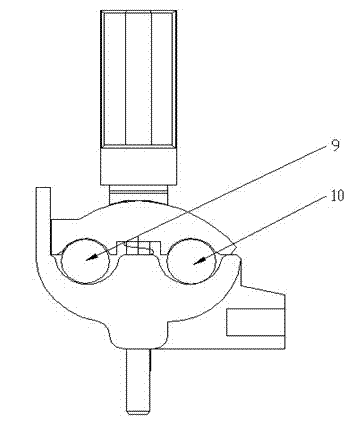

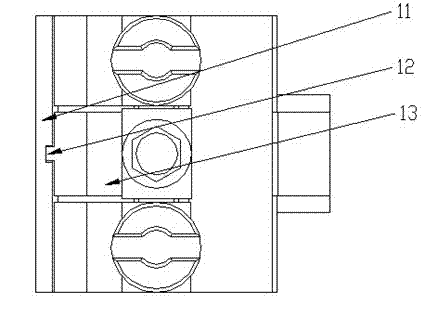

[0023] figure 1 , figure 2 , image 3 Among them, the present invention is mainly composed of three parts: a drain wire pre-fixed crimping device, a main lead wire fixing crimping device and a manipulator clamping device.

[0024] Wherein, the manipulator clamping device comprises a lower fixed support block 7, and the lower fixed support block 7 is provided with a manipulator clamping position 8, and the lower fixed support block 7 is provided with two spaced parallel semicircular arc surfaces, The fixed support block 7 side is provided with the lower fixed support side positioning plate 11, and the lower fixed support side positioning plate 11 is provided with a positioning device;

[0025] The drainage wire pre-fixed crimping device is a drainage wire pre-fixed press block 13, which is tightly connected with the lower fixed support block 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com