Metal phase of cermet inert anode material capable of resisting corrosion of high-temperature molten salt and preparation method and application thereof

A technology of cermets and inert anodes, applied in the field of material science, can solve the problems of high-temperature molten salt corrosion resistance of metal phases to be improved, and achieve the effects of improving molten salt corrosion resistance, stable operation, and improving corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

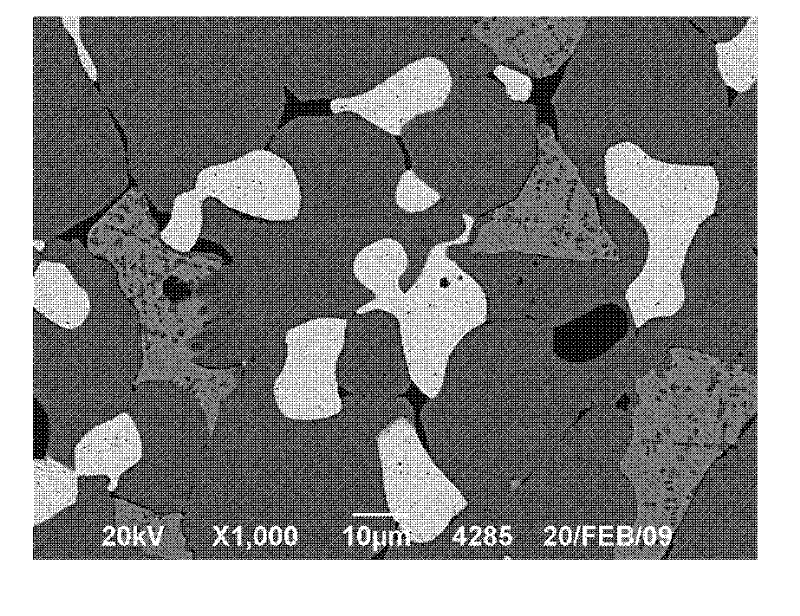

[0038] Embodiment 1: 15 (20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0039] 15(20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formula of cermet inert anode is shown in Table 1.

[0040] Table 115 (20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0041] raw material

Mass percentage (%)

20Ni-80Cu

12.0

Coated NiFe 2 o 4

3.0

NiO

8.5

NiFe 2 o 4

76.5

[0042] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of the substances is 4:1, the co-current co-precipitation method is adopted, the ammonia water is used as the precipitating agent, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the resul...

Embodiment 2

[0044] Embodiment 2: 15 (30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0045] 15(30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 2.

[0046] Table 215 (30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0047] raw material

Mass percentage (%)

20Ni-80Cu

10.5

Coated NiFe 2 o 4

4.5

NiO

8.5

NiFe 2 o 4

76.5

[0048] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of substances is 7:3, the co-current co-precipitation method is adopted, ammonia water is used as the precipitating agent, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the resul...

Embodiment 3

[0050] Embodiment 3: 15 (40NiFe2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0051] 15 (40NiFe 2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 3.

[0052] Table 315 (40NiFe 2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0053] raw material

Mass percentage (%)

20Ni-80Cu

9.0

Coated NiFe 2 o 4

6.0

NiO

8.5

NiFe 2 o 4

76.5

[0054] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of the substances is 3:2, the co-current co-precipitation method is adopted, ammonia water is used as the precipitant, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the resulting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com