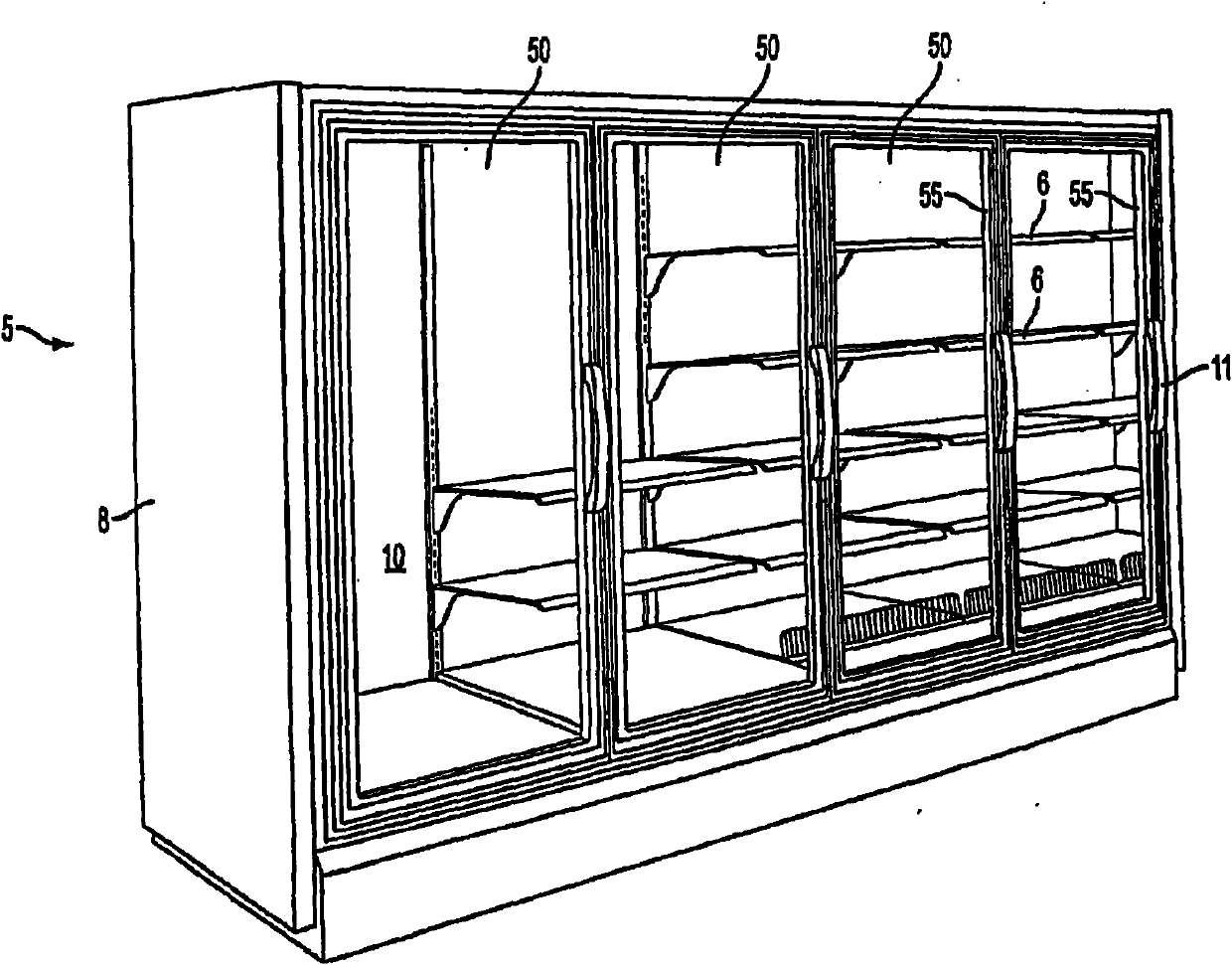

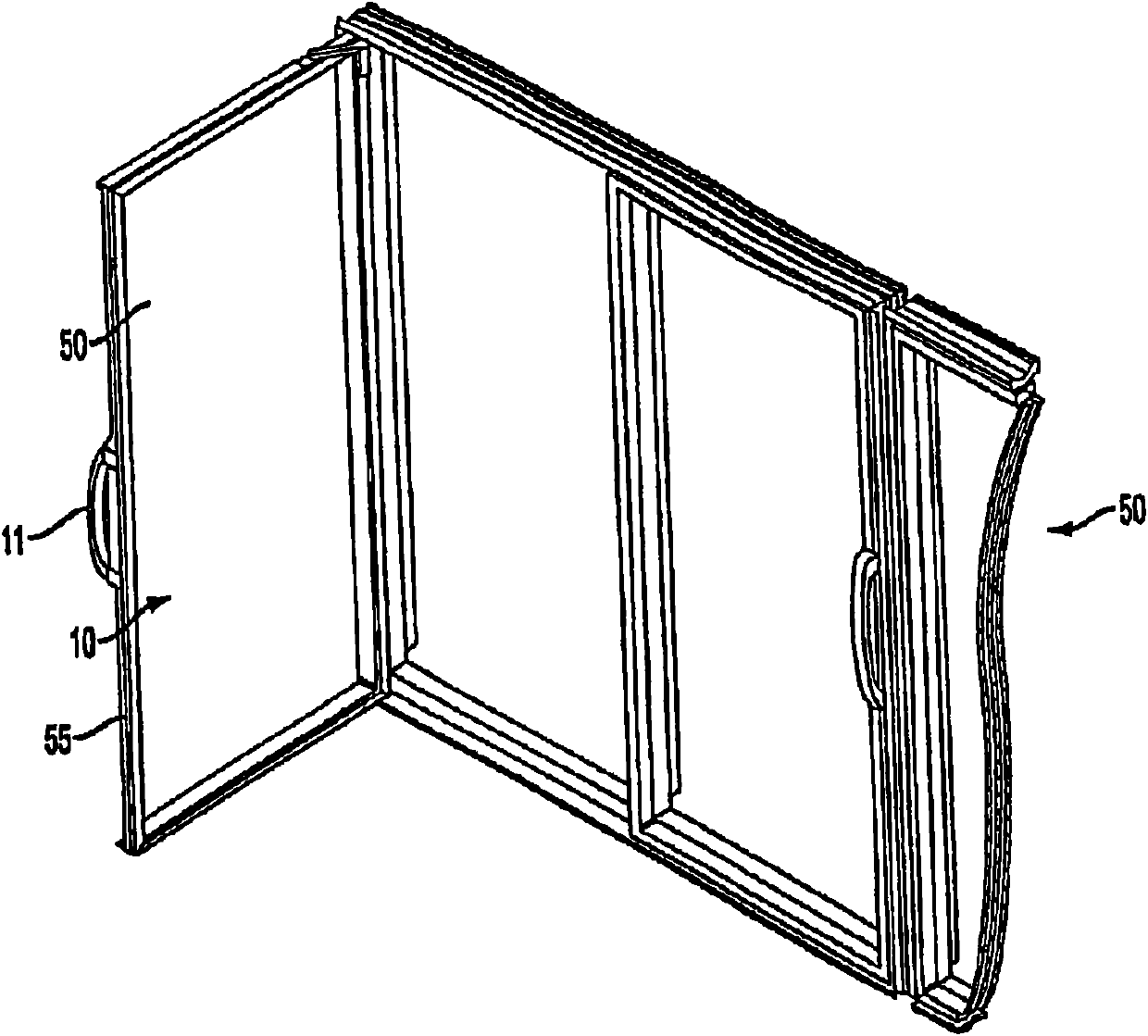

Anti-fog refrigeration door and method of making the same

An anti-fog and anti-frost technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of loss of anti-fog, reliability and reputation, potential danger, dust trapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

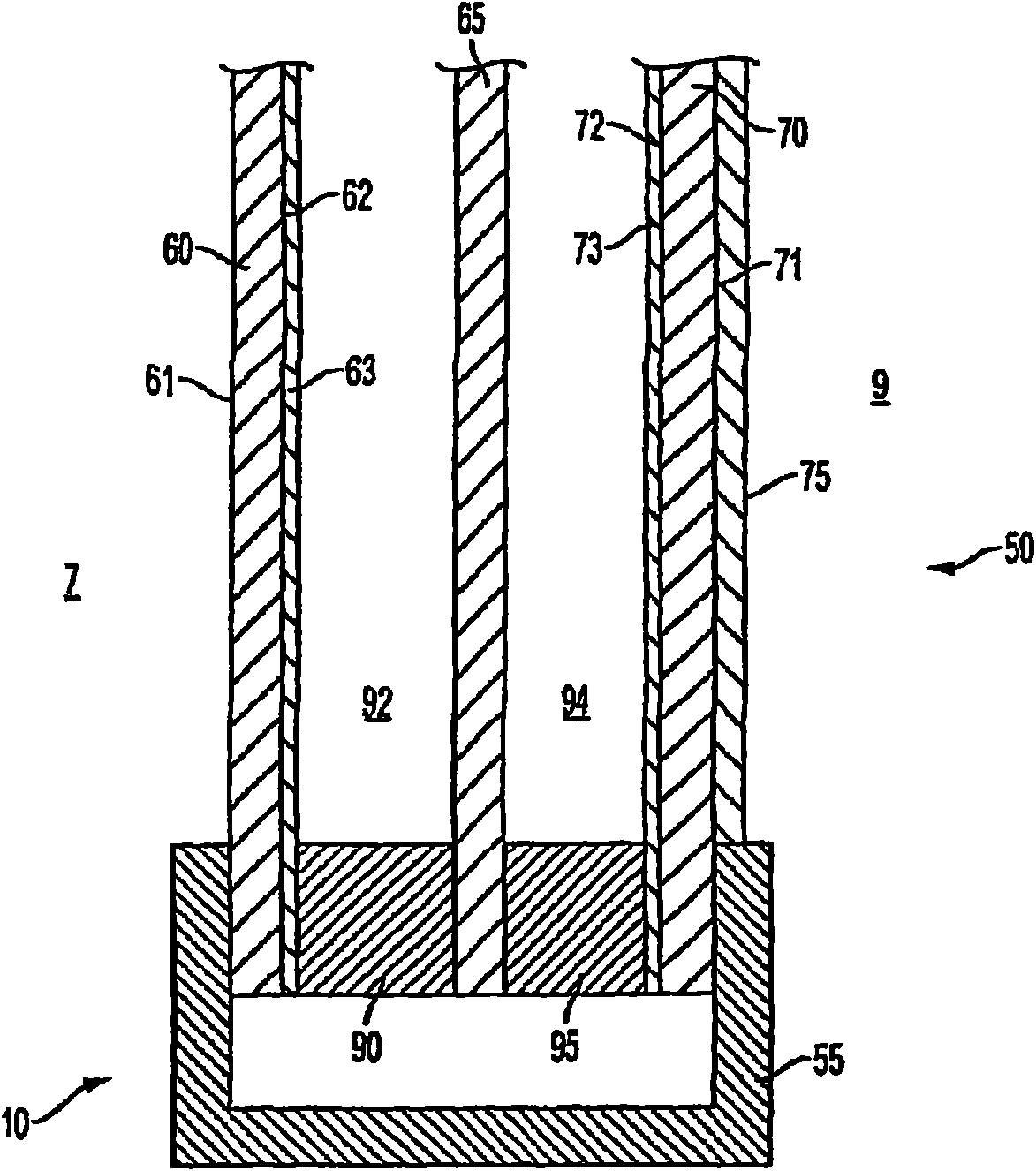

Embodiment Construction

[0043] In the following description, for purposes of explanation and not limitation, specific details are given, such as specific coatings, coating processes, panel and film thicknesses, sealing components, number of layers of panels, spacing of panels, and method of assembling the door etc., so that the present invention can be thoroughly understood. However, it will be understood by those of ordinary skill in the art that the present invention may be practiced in other embodiments that differ from these specific details. Detailed descriptions of well-known coatings, coating processes, sealant components, and methods of assembling a door will be omitted in order not to obscure the description of the present invention. For purposes of describing the present invention, terms such as external, internal, outside and inside are described from the perspective of the interior of the freezer or refrigerator compartment, as evident from the drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com