Multisource dynamic pressure isopressing powder molding process

A technology of powder molding and isostatic pressing, which is applied to presses, manufacturing tools, etc., can solve the problems of high driving pressure and high cost, and achieve the effects of ensuring density, reducing friction, and preventing the rise of forming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

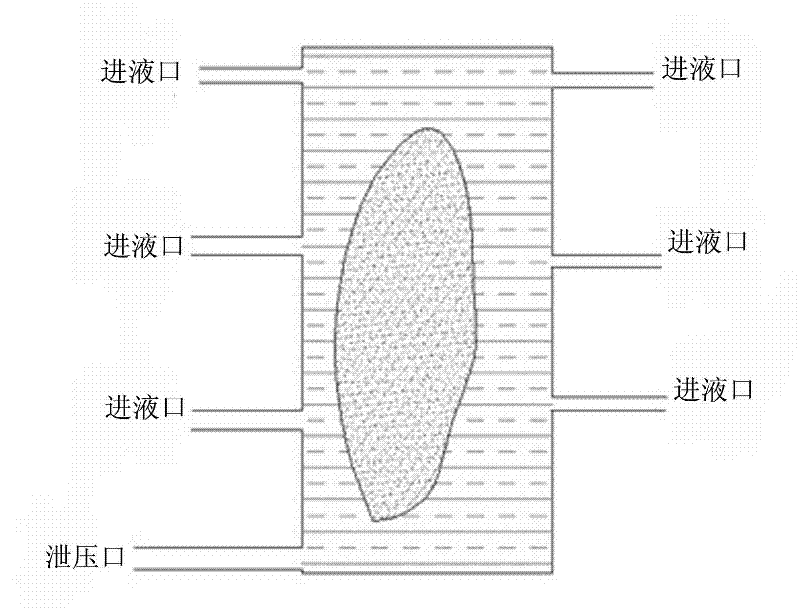

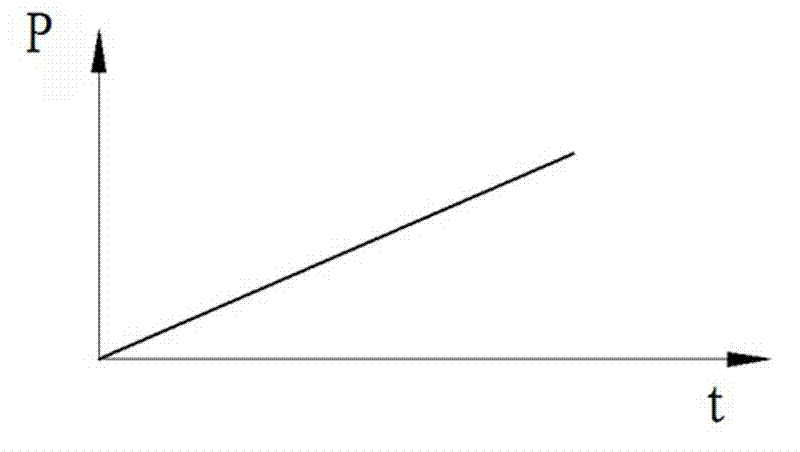

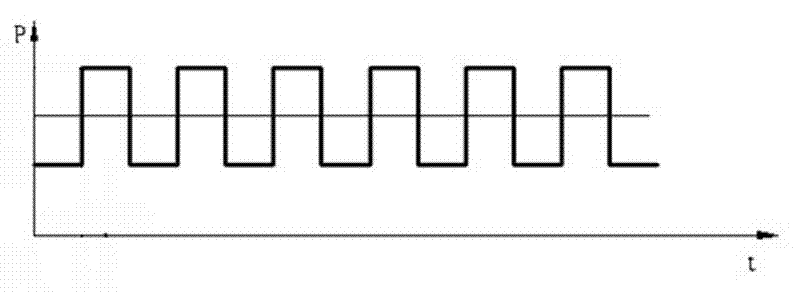

[0014] Multi-source dynamic pressure isostatic pressing powder molding process, which is realized by the following steps:

[0015] (1) Place the bag containing the powder in the inner cavity of the working cylinder of the isostatic press, and open a pressure relief port and several liquid inlets on the wall of the working cylinder, and then install a pulsating Pressure power source; (2) Seal the inner cavity of the working cylinder; (3) Fill the working fluid into the inner cavity of the working cylinder through each liquid inlet to stably increase the pressure. During the process of stabilizing the boost, each pulsating pressure power source Corresponding liquid inlets superimpose pulsating pressure successively. The pulsating pressures of each liquid inlet interfere with each other and form a randomly changing dynamic pressure field in the working cylinder. The dynamic pressure field squeezes the powder in the sheath to ensure During the molding process, the powder is evenly...

Embodiment 2

[0019] Multi-source dynamic pressure isostatic pressing powder molding process, which is realized by the following steps:

[0020] (1) Place the bag containing the powder in the inner cavity of the working cylinder of the isostatic press, and open a pressure relief port and several liquid inlets on the wall of the working cylinder, and then install a pulsating Pressure power source; (2) Seal the inner cavity of the working cylinder; (3) Fill the working fluid into the inner cavity of the working cylinder through each liquid inlet to stably increase the pressure. During the process of stabilizing the boost, each pulsating pressure power source Corresponding liquid inlets superimpose pulsating pressure successively. The pulsating pressures of each liquid inlet interfere with each other and form a randomly changing dynamic pressure field in the working cylinder. The dynamic pressure field squeezes the powder in the sheath to ensure During the molding process, the powder is evenly...

Embodiment 3

[0024] Multi-source dynamic pressure isostatic pressing powder molding process, which is realized by the following steps:

[0025] (1) Place the bag containing the powder in the inner cavity of the working cylinder of the isostatic press, and open a pressure relief port and several liquid inlets on the wall of the working cylinder, and then install a pulsating Pressure power source; (2) Seal the inner cavity of the working cylinder; (3) Fill the working fluid into the inner cavity of the working cylinder through each liquid inlet to stably increase the pressure. During the process of stabilizing the boost, each pulsating pressure power source Corresponding liquid inlets superimpose pulsating pressure successively. The pulsating pressures of each liquid inlet interfere with each other and form a randomly changing dynamic pressure field in the working cylinder. The dynamic pressure field squeezes the powder in the sheath to ensure During the molding process, the powder is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com