Plasma cutting torch protection and collision detection device of numerically controlled plasma cutting machine

A plasma cutting machine and collision detection technology, which is applied in plasma welding equipment, auxiliary equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the quality of perforation cannot be guaranteed, the collision height point cannot be accurately measured, and the accuracy of sensors is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

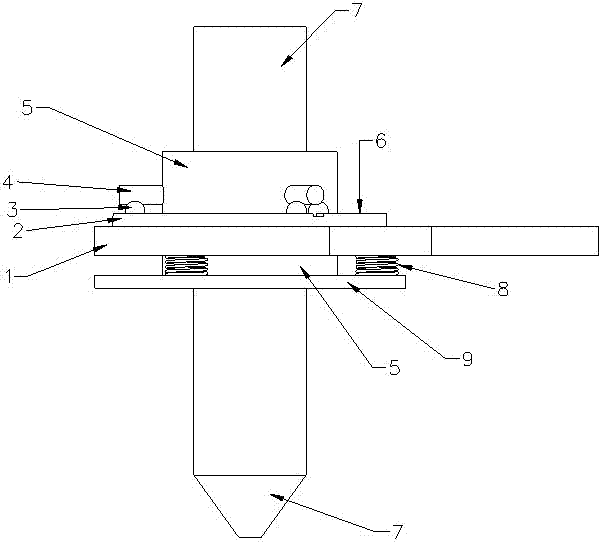

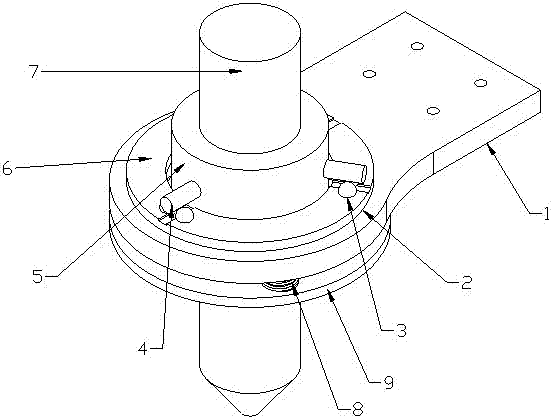

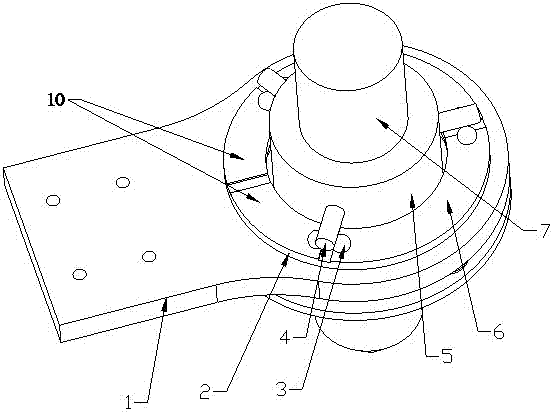

[0016] In the plasma cutting torch protection and collision detection device of the present invention, a positioning plate 2 is installed on the base plate 1 of the device, and the plasma cutting torch mounting seat 5 is installed in the through holes of the base plate 1 and the positioning plate 2; the upper surface of the positioning plate 2 is a conductive layer 6 , three pairs of evenly distributed steel balls 3 are installed on the positioning plate 2, and the steel balls 3 are in contact with the conductive layer 6; Contact; the bottom of the plasma cutting torch mounting seat 5 is a flange 9, and three springs 8 are evenly distributed between the flange 9 and the bottom plate 1 to keep the metal pin 4 in contact with the steel ball 3; there is a plasma cutting torch mounting seat 5 in the middle. The installation hole of the cutting torch 7, the plasma cutting torch 7 is installed in the installation hole of the plasma cutting torch mounting seat 5; one end of the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com