Extractor hood

A range hood and smoke technology, applied in the direction of removing oil fume, mechanical equipment, thin plate connection, etc., can solve problems such as loosening, achieve the effect of simple cleaning and improve appearance and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

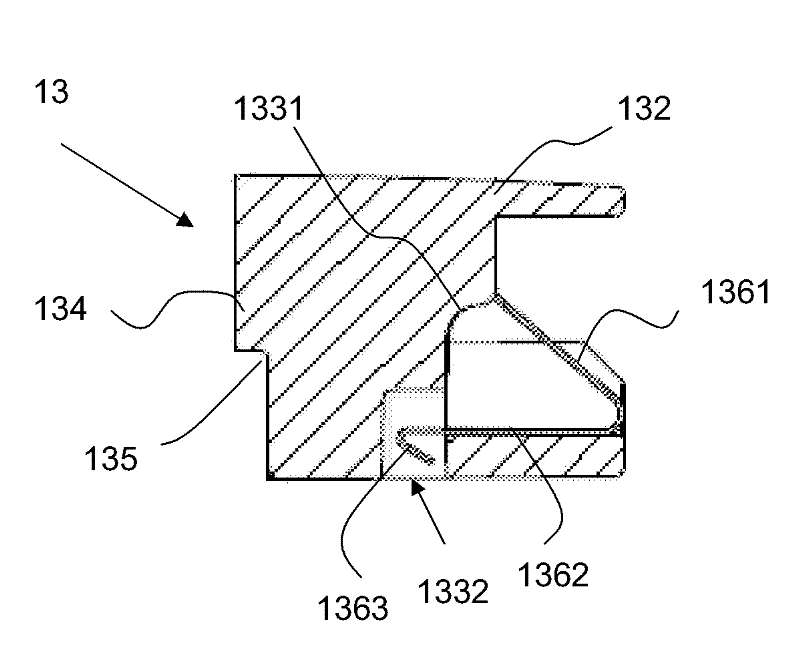

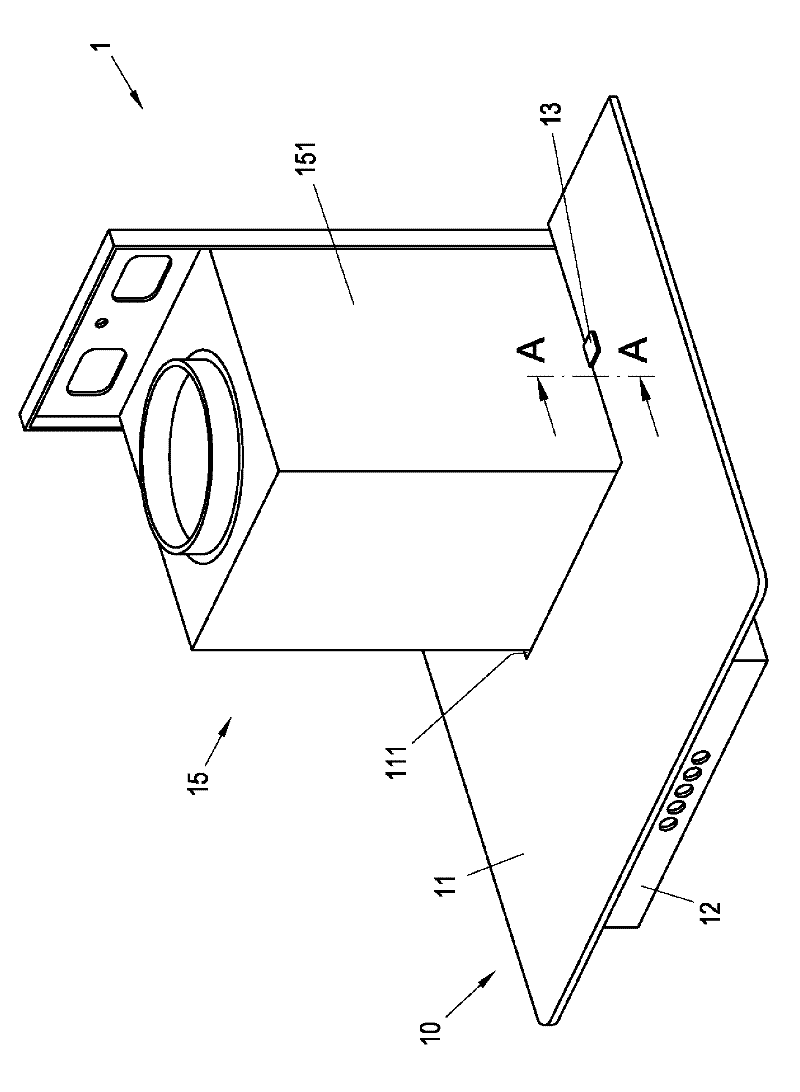

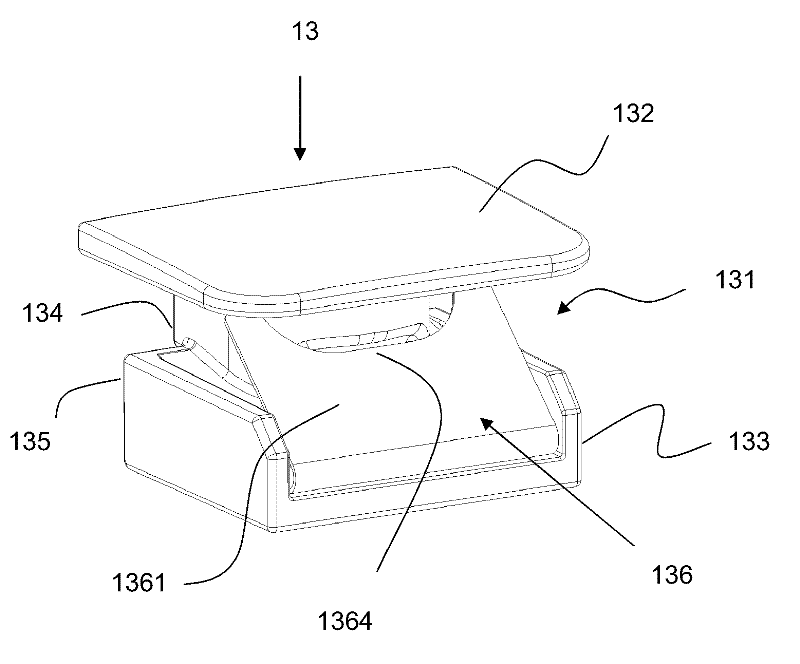

[0037] exist figure 1 An embodiment of the cooker hood 1 according to the invention is shown schematically in a perspective view. The range hood includes a fan box 15 having a box-shaped channel 151 . A pipe connection is inserted on the upper side of this channel 151 as an air outlet. The fan box 15 is surrounded on three sides by the fume cover 10 at its lower end. The smoke cover 10 includes a smoke cover plate 11 and a visible cover 12 . In the embodiment shown, the fume shield 11 is a single-piece flat glass element. A recess 111 is provided centrally in the rear side of the fume shield 11 , in which recess a channel 151 of the fan box 15 is accommodated. The smoke hood panel 11 is held on a visible hood 12 . In the illustrated embodiment, the visible cover 12 is a sheet-metal frame, in the back of which a central recess 121 is likewise provided. The recesses 111 in the smoke hood panel 11 coincide with the recesses 121 in the visible hood 12 , that is to say they a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com