Immediate processing method for drainage solidifying of super soft soil shallow surface space

A drainage consolidation and treatment method technology, which is applied in the engineering field of ultra-weak foundation reinforcement, can solve problems such as inapplicability, achieve effective drainage consolidation, improve transfer and drainage efficiency, and avoid air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

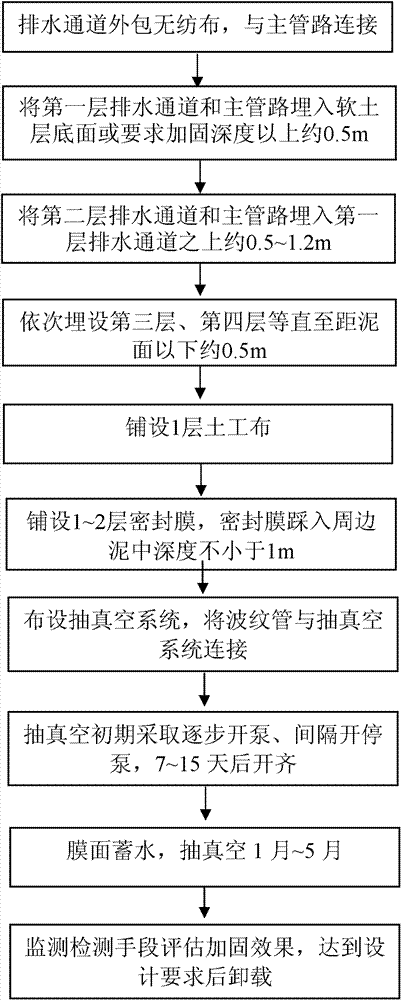

[0030] (1) Process horizontal drainage channel: use plastic blind ditch, soft permeable pipe, PVC filter pipe, sand blind ditch, sand belt and other materials as the core material of drainage channel, and wrap a layer of 90-200g / m 2 Drainage channels made of non-woven fabric.

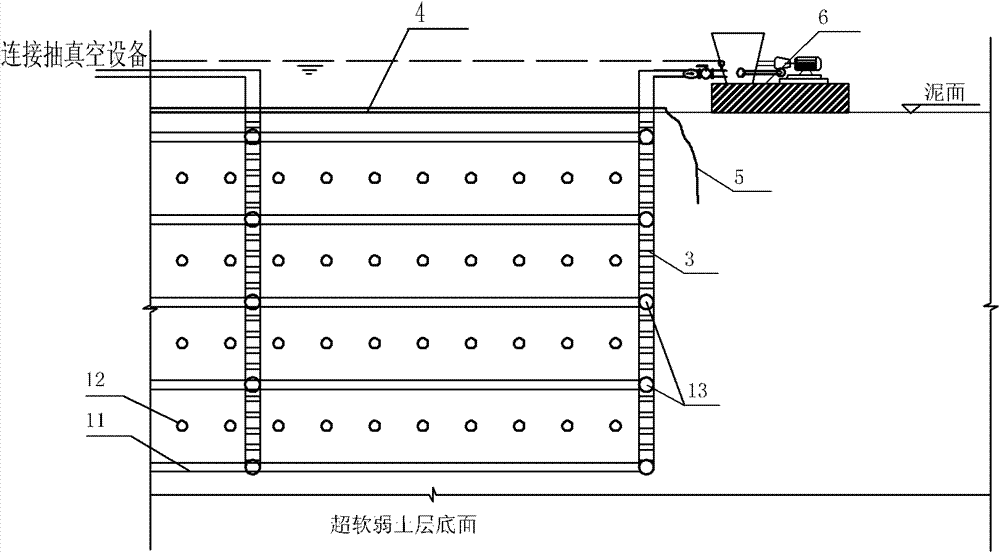

[0031] (2) Bury the first layer of horizontal drainage channel network: if figure 1 As shown, horizontal drainage channels 11 are laid out at a parallel interval of 0.5-1.2m on the super-soft foundation surface, and a horizontal horizontal collecting pipe is connected to both ends of the horizontal drainage channel 11, and a horizontal horizontal collecting pipe is connected to each interval of 30-50m. , forming a layer of horizontal drainage channel network. The horizontal collecting pipes are separated by a certain interval, and the specific interval can be determined according to the power of the vacuum system and the length and width of the reinforcement area. Bellows 3 connections.

[0032] Pres...

Embodiment 2

[0041] (1) Process the horizontal drainage channel according to Example 1, using materials such as plastic blind ditch, soft permeable pipe, PVC filter pipe, sand blind ditch, abrasive belt, etc. as the drainage channel core material, and wrap a layer of 90 ~ 200g / m 2 of non-woven fabrics.

[0042](2) Bury the first layer of horizontal drainage channel network: if figure 2 As shown, horizontal drainage channels 11 are laid out on the super-soft foundation surface at a parallel spacing of 0.5-1.2m, and longitudinal drainage channels 12 are laid at a parallel spacing of 0.5-1.2m. The two ends of the horizontal drainage channel 11 are connected to the horizontal horizontal collecting pipe 13, and a horizontal horizontal collecting pipe is set at an interval of 30-50m; similarly, the vertical drainage channel 12 is also connected to its vertical horizontal collecting pipe, which is set at an interval of 30-50m A longitudinal horizontal collecting pipe, thereby forming a layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com