Method for rapidly reinforcing ultra-soft soil superficial zone and packaged technology

A technology for ultra-soft soil and shallow surface layer, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of large differential settlement after construction, high construction cost, low construction efficiency, etc., and achieve easy maintenance of vacuum equipment, The effect of small mutual construction interference and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

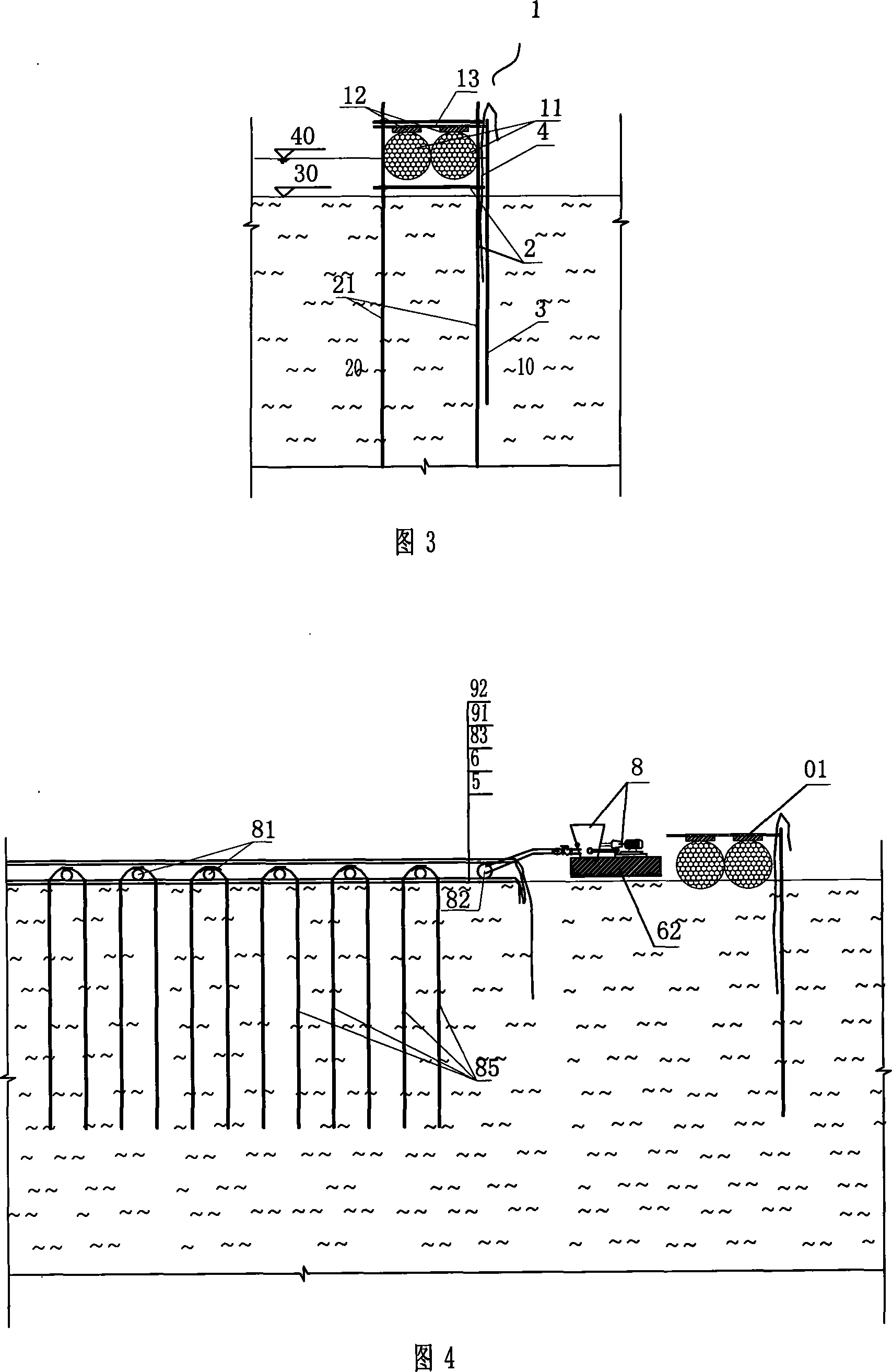

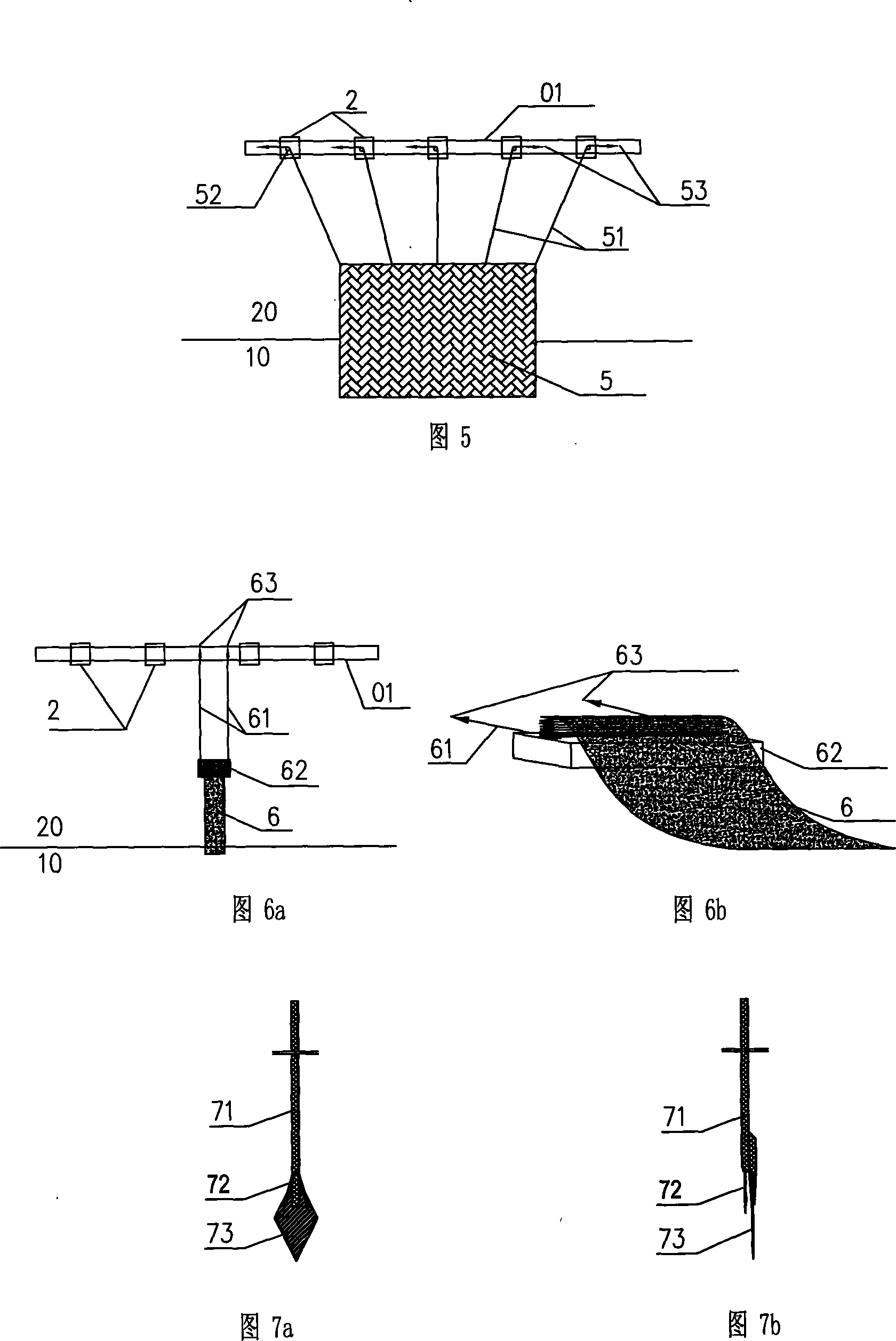

[0033] Follow the steps below to carry out rapid reinforcement construction of ultra-soft soil:

[0034] (1) Construct and form a shallow surface soft soil reinforcement device.

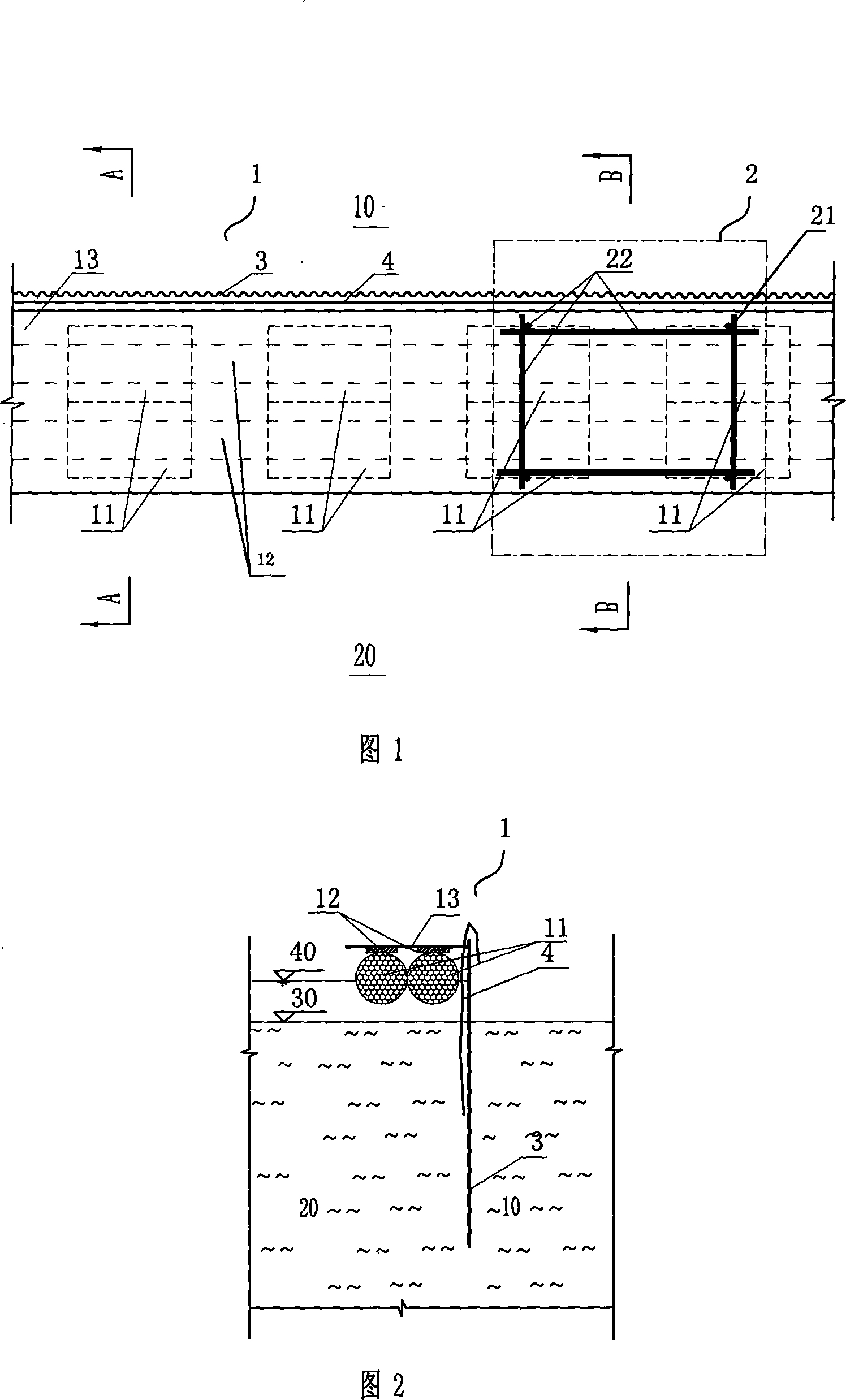

[0035] First, as shown in FIGS. 1-4 , a partition curtain 01 is set up in the area to be reinforced 20 for construction division. Wherein, in Fig. 2, 10 is outside the reinforcement area, 20 is inside the reinforcement area, 30 is the floating mud surface, and 40 is the water storage level. Since the surface of the ultra-soft ground to be treated is usually floating mud or silt, it is difficult to lay geotextiles on the surface manually, and it is necessary to use the buoyancy of water to lay the geotextile on the surface after the site is covered with water.

[0036] The partition curtain 01 includes: plastic foam 11 , wooden strips 12 , planks 13 , derrick fixing device 2 , color steel plate 3 , and plastic film 4 .

[0037] Two rows of plastic foam 11 are arranged longitudinally along the partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com