Double-faced jacquard circular knitting machine capable of weaving terry weave

A technology of double-sided jacquard and circular knitting machine, which is applied to circular weft knitting, weft knitting, knitting and other directions with separate action needles, and can solve the problems of inability to weave and inseparable from double-sided rib.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

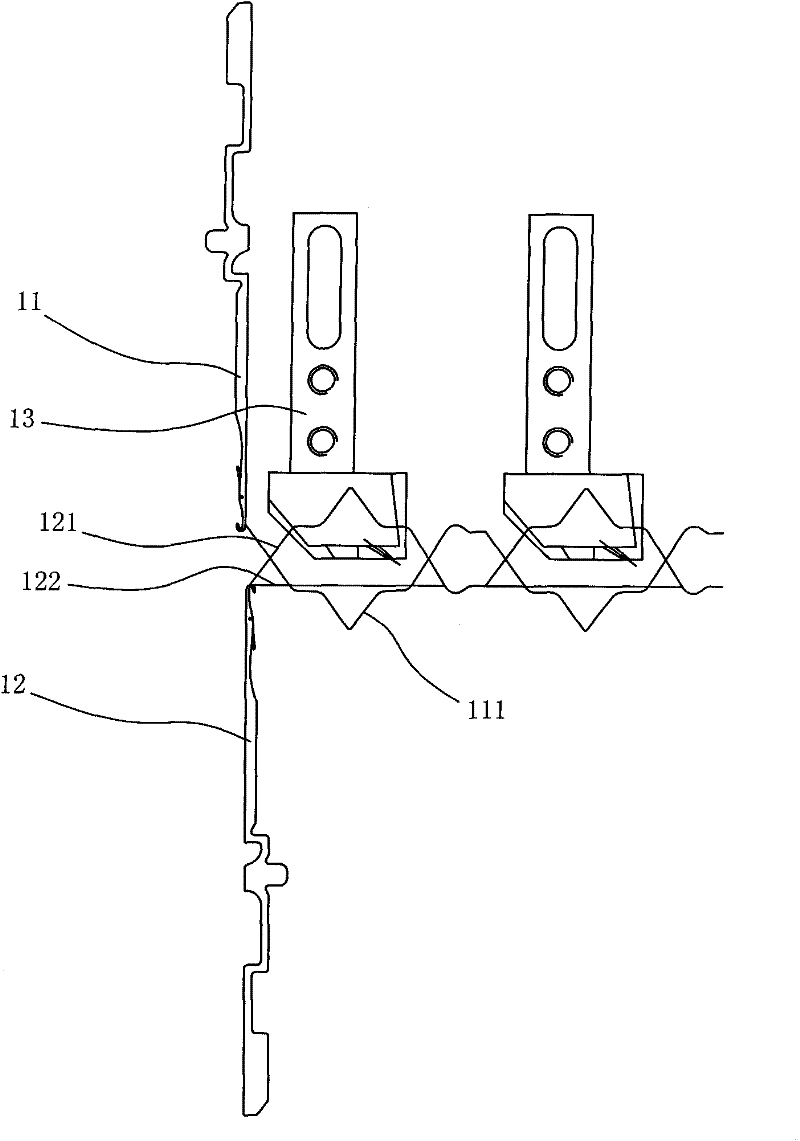

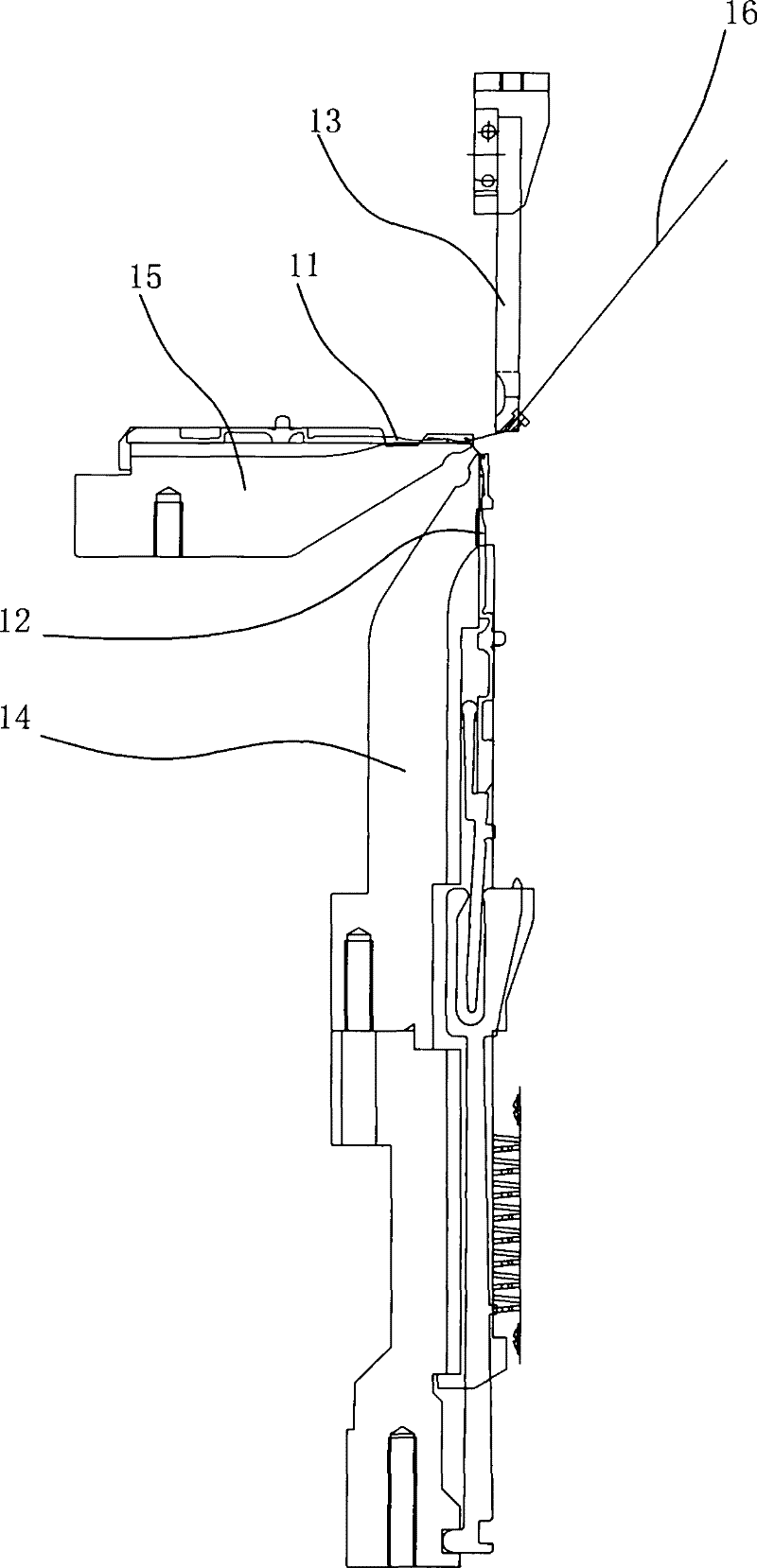

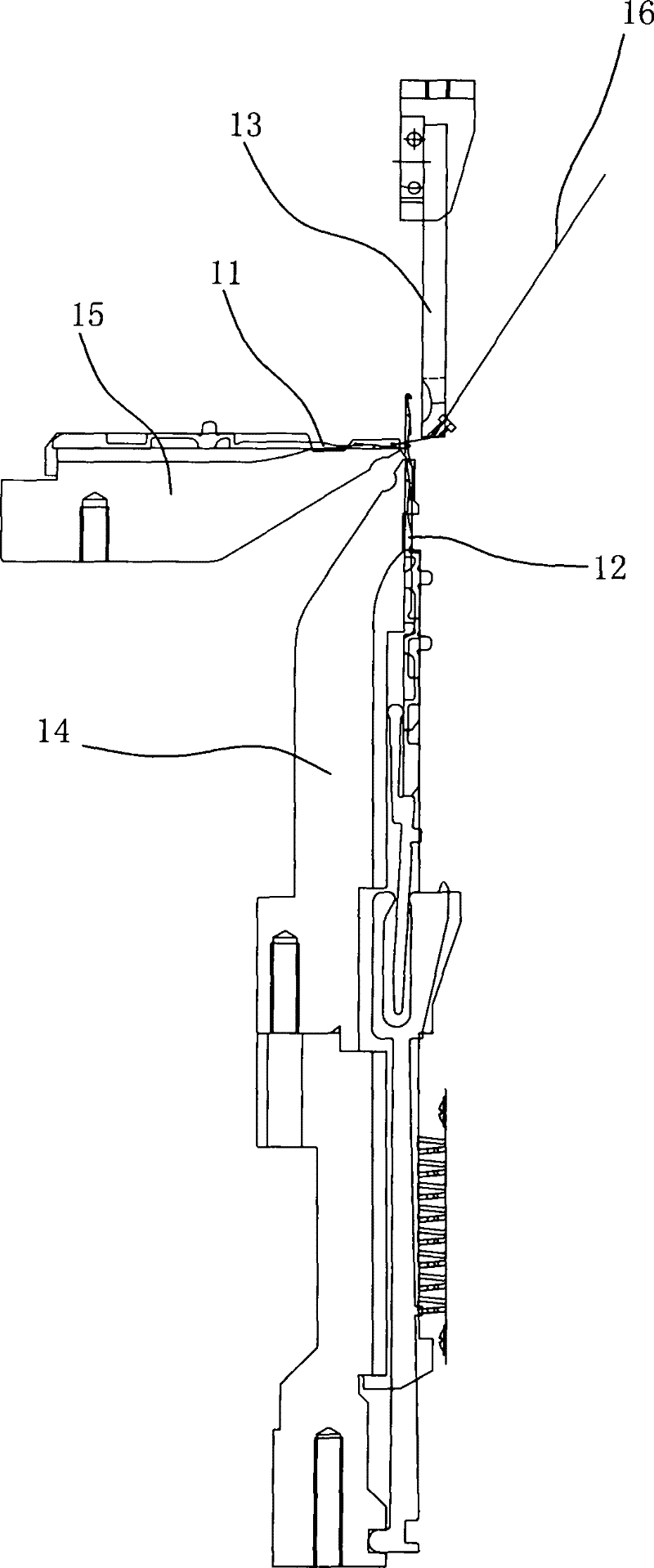

[0023] refer to Figure 4 to Figure 7 As shown, in order to more simply and intuitively represent the weaving principle of the present invention, the Figure 4 The upper knitting needle 1 which is originally arranged horizontally is shown vertically.

[0024] A double-sided jacquard circular knitting machine capable of weaving towels, including a needle cylinder 4, an upper dial 5, a lower needle groove distributed vertically on the outer peripheral surface of the needle cylinder 4, and an upper needle distributed radially on the upper end surface of the upper dial 5. Slots, upper and lower knitting needles 1,2 movable in the upper and lower needle grooves, multi-way cam device (not shown) for driving the upper and lower knitting needles 1,2 to cooperate to complete the knitting action, and The needle selection system (not shown in the figure), the above is the main structure of the known double-sided jacquard circular knitting machine, which will not be described one by one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com