MEMS infrared emission gas-sensitive sensor

A technology of gas sensor and infrared emission, which is applied in the field of gas sensor, can solve the problems of low sensitivity of MEMS gas sensor, limited detectable gas, complex process, etc., and achieve the effect of on-chip integration, simple design and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the present invention more clear, the following will be combined with the analysis of chloroform vapor in the ambient gas as a specific example, and with reference to the accompanying drawings, the present invention will be further described in detail.

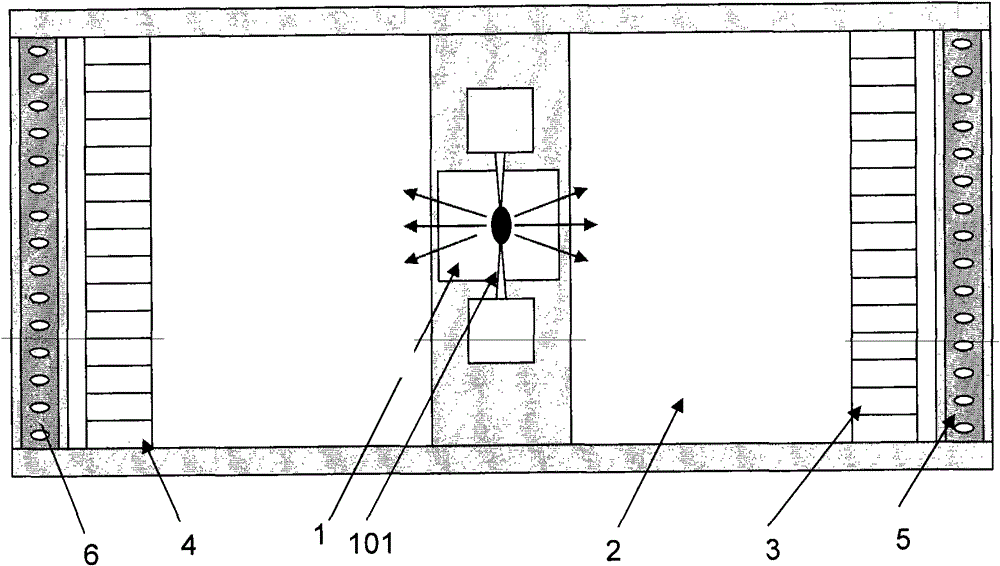

[0028] Such as figure 1 as shown, figure 1 The structural schematic diagram of the MEMS infrared emitting gas sensor provided for the present invention, the sensor is mainly composed of a gas light emitting tube 1, an absorption gas chamber 2, an emission spectrum splitting array 3, an absorption spectrum splitting array 4, an emission spectrum detection array 5, an absorption spectrum detection array The array consists of 6 etc. parts.

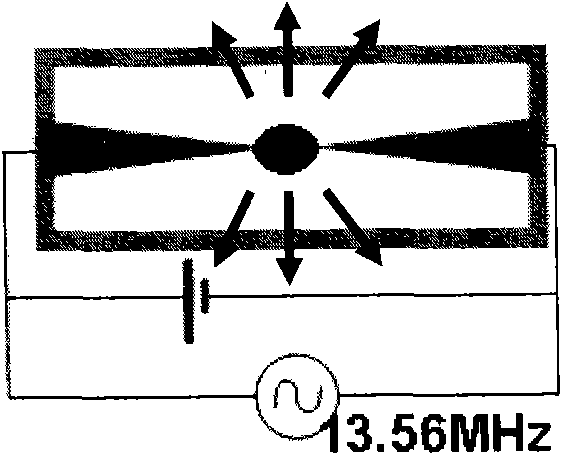

[0029] Such as figure 2 As shown, the gas luminous tube 1 is an open structure made on a silicon wafer, with a platinum electrode 101 inside, and a matching network on the external circuit. After electrification, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com