Automatic weighing method and device for various materials

An automatic weighing and material type technology, applied in the direction of measuring devices, weighing, weighing equipment for continuous material flow, etc., can solve the problems of low data accuracy, equipment versatility, and easy maintenance constraints on system applicability, data Error and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Example: figure 1 , figure 2 As shown, it includes an electronic belt scale, a programmable logic controller (PLC for short), and a computer. The output of the electronic belt scale is connected to the input of the programmable controller, the output of the programmable controller is connected to the input of the computer, and the output of the computer is connected to the The input of the server, the output of the server is connected to the input of the monitor.

[0026] The electronic belt scale is equipped with a flow acquisition module, which is responsible for collecting the flow signal (unit t / h) of the material transported by the belt;

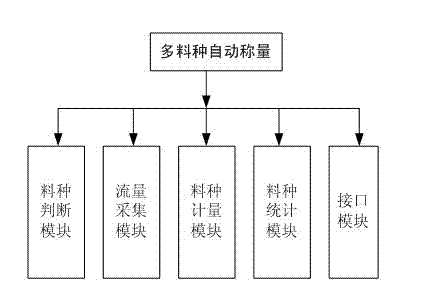

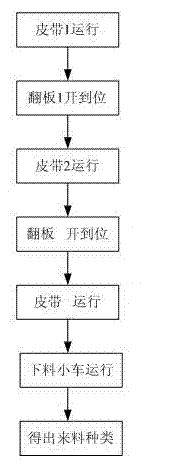

[0027] The programmable controller is equipped with a flow collection module, a material type judgment module, and a material type metering module to collect the operation signals of the relevant belts, collect instantaneous quantities through the "flow collection module", and automatically pass through the "material type judgm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com