Separation technique for low pressure oxygen-enriched air

An oxygen-enriched air and low-pressure technology, which is applied in the field of low-pressure oxygen-enriched air separation technology, can solve the problems of high energy consumption and complicated operation for oxygen production, and achieve the effects of low power consumption for oxygen production, simple process flow, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

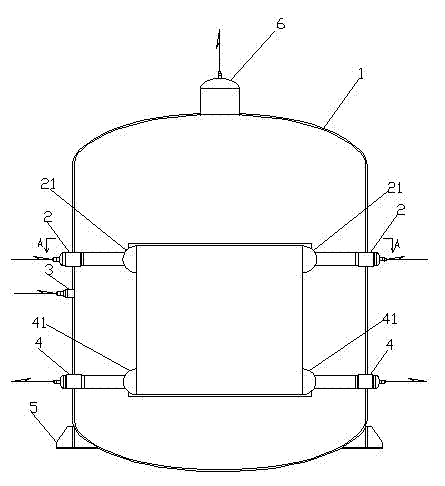

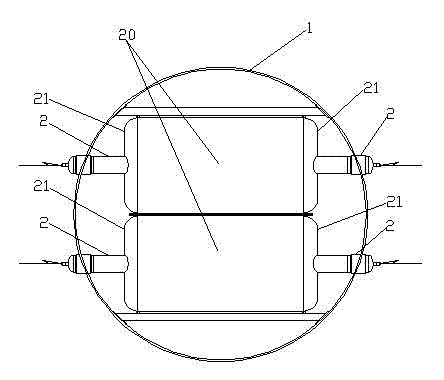

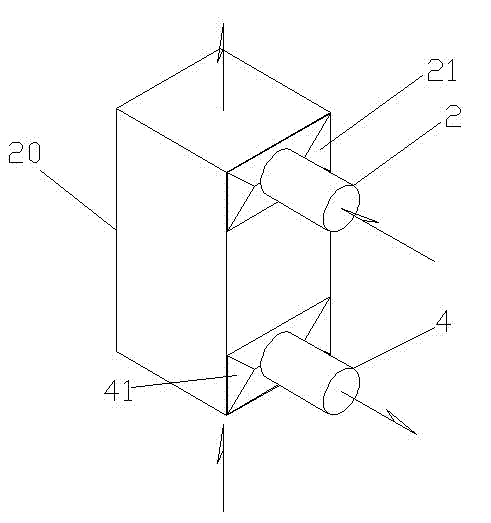

[0019] Low-pressure oxygen-enriched air separation process, the steps are: (1) The air is filtered through the filter to remove dust and mechanical impurities, enters the air compressor to compress to 0.33MPa, then cools to 5°C, and continues to be sent to the molecular sieve adsorber for purification; (2) ) The purified air is divided into two paths, one path enters the expansion gas channel of the main heat exchanger of the air fractionation column as expansion air, and then is drawn out from the middle of the main heat exchanger and enters the expander for expansion, and the other path air is cooled to the dew point temperature and passed through oxygen The evaporator enters the lower tower of the air fractionation tower for rectification, and the oxygen-rich liquid air is obtained from the bottom of the lower tower of the air fractionation tower, and nitrogen is obtained from the top of the lower tower of the air fractionation tower; (3) the oxygen-rich liquid air at the bot...

Embodiment 2

[0024] Low-pressure oxygen-enriched air separation process, the steps are: (1) The air is filtered through the filter to remove dust and mechanical impurities, enters the air compressor to compress to 0.38MPa, then cools to 8°C, and continues to be sent to the molecular sieve adsorber for purification; (2) ) The purified air is divided into two paths, one path enters the expansion gas channel of the main heat exchanger of the air fractionation column as expansion air, and then is drawn out from the middle of the main heat exchanger and enters the expander for expansion, and the other path air is cooled to the dew point temperature and passed through oxygen The evaporator enters the lower tower of the air fractionation tower for rectification, and the oxygen-rich liquid air is obtained from the bottom of the lower tower of the air fractionation tower, and nitrogen is obtained from the top of the lower tower of the air fractionation tower; (3) the oxygen-rich liquid air at the bot...

Embodiment 3

[0027] Low-pressure oxygen-enriched air separation process, the steps are: (1) The air is filtered through the filter to remove dust and mechanical impurities, enters the air compressor to compress to 0.44MPa, then cools to 10°C, and continues to be sent to the molecular sieve adsorber for purification; (2) ) The purified air is divided into two paths, one path enters the expansion gas channel of the main heat exchanger of the air fractionation column as expansion air, and then is drawn out from the middle of the main heat exchanger and enters the expander for expansion, and the other path air is cooled to the dew point temperature and passed through oxygen The evaporator enters the lower tower of the air fractionation tower for rectification, and the oxygen-rich liquid air is obtained from the bottom of the lower tower of the air fractionation tower, and nitrogen is obtained from the top of the lower tower of the air fractionation tower; (3) the oxygen-rich liquid air at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com