Exposed frame glass curtain wall structure adopting PVC (polyvinyl chloride) heat insulation bar

A glass curtain wall and thermal insulation strip technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large thermal deformation temperature, high cost, falling off, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

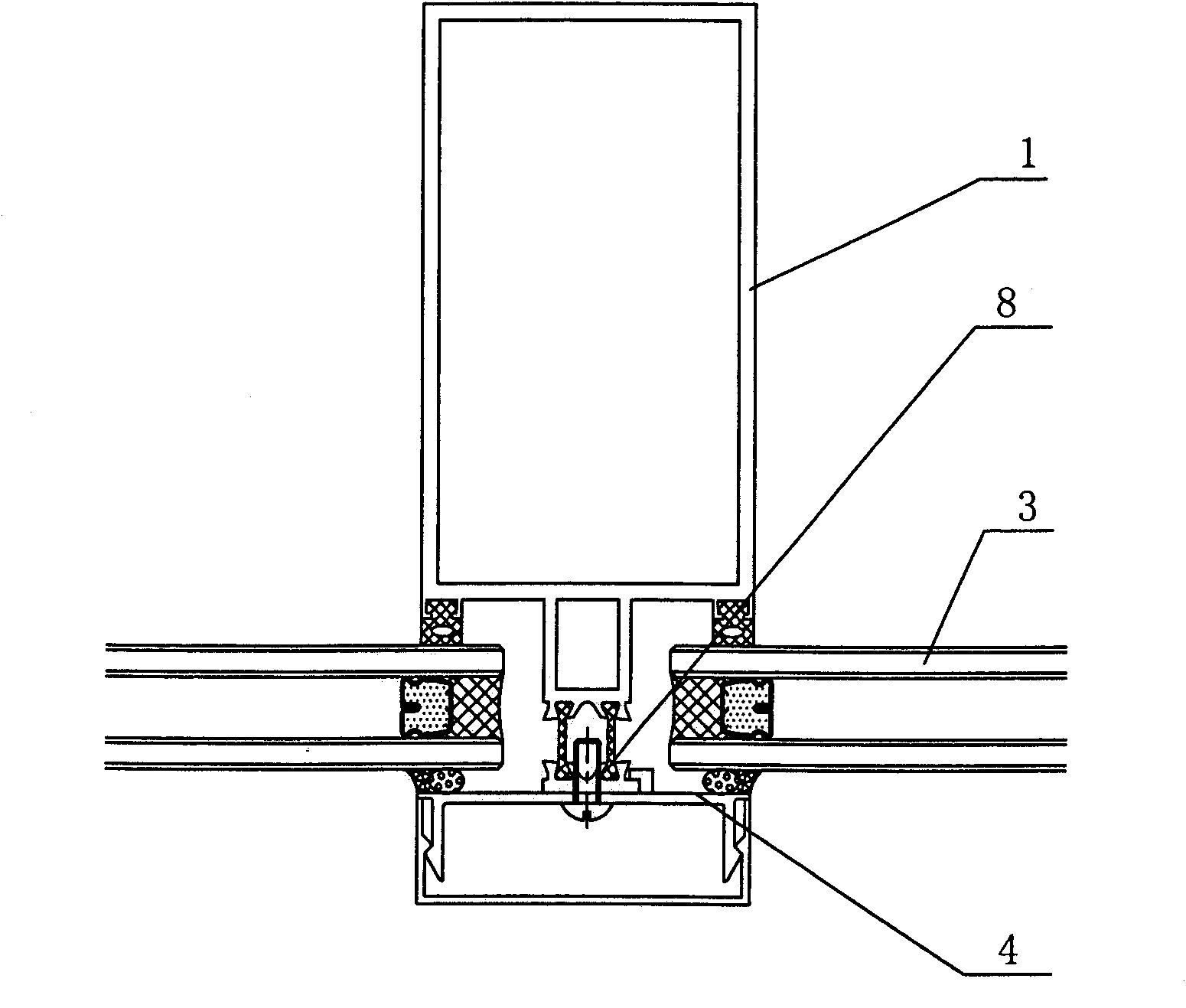

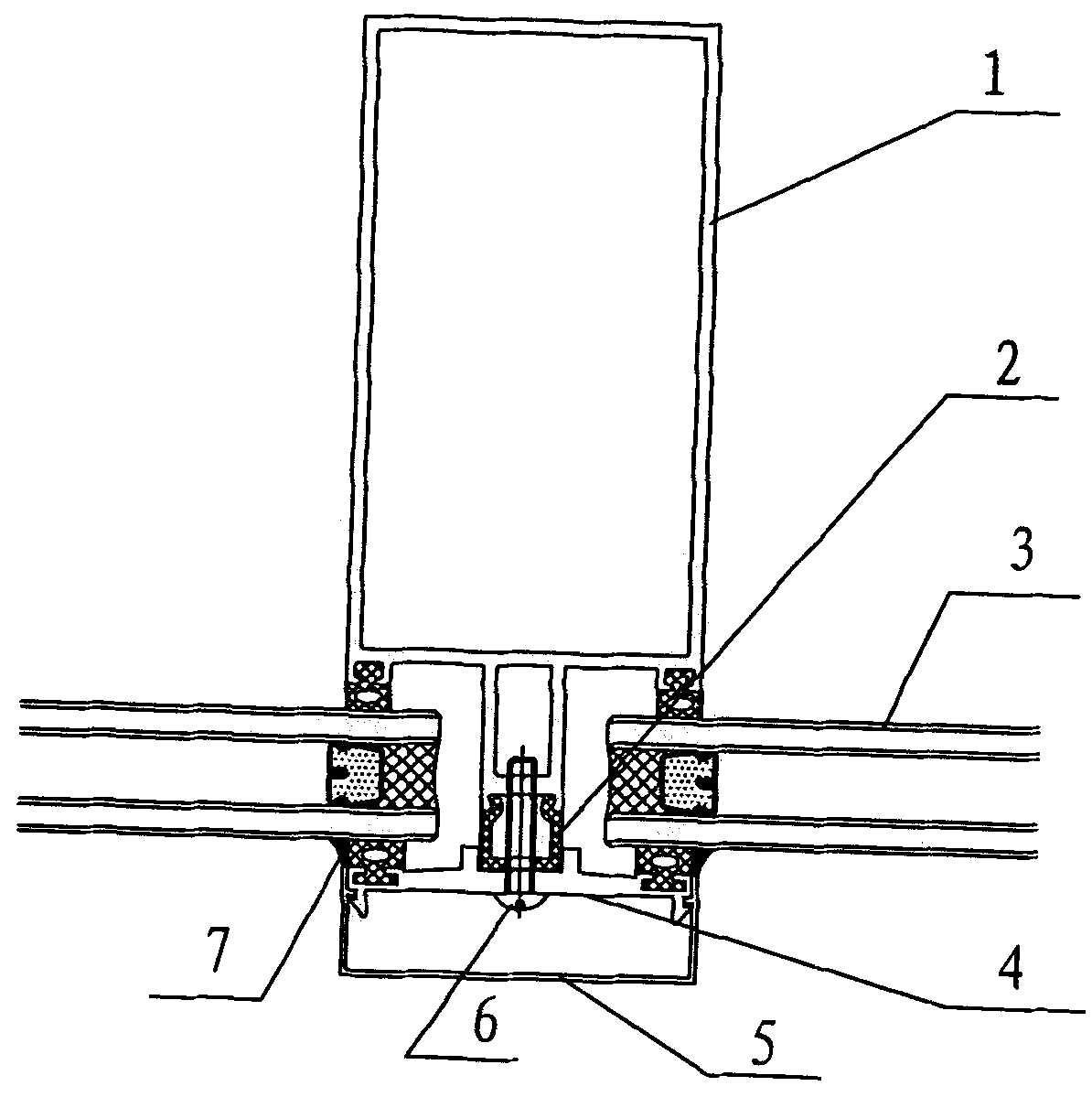

[0014] see figure 2 , figure 2 It is a cross-sectional view of the glass curtain wall structure column of the PVC heat-insulating strip display frame of the present invention. Depend on figure 2 It can be seen that the framed glass curtain wall structure of the PVC heat insulation strip of the present invention includes a column and an insulating glass 3, and the column includes an aluminum profile 1, a PVC heat insulation strip 2, an inner cover plate 4 of an aluminum profile, and an outer cover plate 5 of an aluminum profile and screws 6, the aluminum profile inner cover 4 is placed on the aluminum profile 1, the aluminum profile outer cover 5 is placed outside the aluminum profile inner cover 4, and the hollow glass 3 is embedded in the aluminum profile through the sealing strip 7 1 and the aluminum profile inner cover plate 4, the PVC heat insulation strip 2 is embedded between the aluminum profile 1 and the aluminum profile inner cover plate 4, and the aluminum profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com