Warp-weft directional elongation deviation minimization process of fabric for airbag

An airbag, elongation technology, applied in the direction of fabric surface trimming, liquid/gas/vapor removal with squeeze rollers, heating/cooling fabric, etc. Waste, cost reduction, small shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below through specific embodiments. The embodiments are helpful to the understanding and implementation of the present invention, and are not intended to limit the present invention; the protection scope of the present invention is defined by the claims.

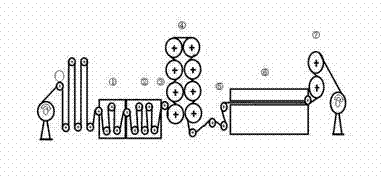

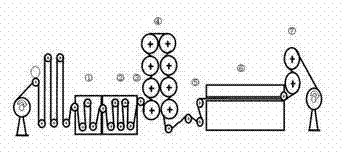

[0019] The warp and weft elongation deviation minimization process of the airbag fabric of the present invention, the schematic diagram of its process flow is as follows figure 1 , the gray fabric is ①refined by chemicals, ②rinsed, then ③extruded and filtered, ④steam drying roller is closed, and enters the oven for heat treatment. After ⑤overfeed adjustment, ⑥width and temperature adjustment, and finally ⑦cooling, the fabric is formed .

[0020] The airbag fabric is sorted through the following steps, and the warp and weft elongation deviation of the molded fabric can meet the minimum requirement. The method includes:

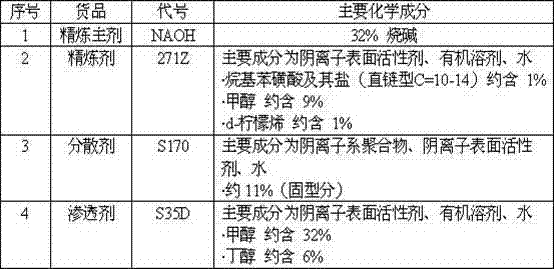

[0021] 1. Washing and refining: the fabric is wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com