Method for preparing V-ZSM-5 molecular sieve and catalytic property of molecular sieve on preparation of cyclohexanol and cyclohexanone by oxidizing cyclohexane

A technology of V-ZSM-5 and ZSM-5, which is applied in the field of preparation of V-ZSM-5 molecular sieve and its catalytic performance for the oxidation of cyclohexane to prepare cyclohexanol and cyclohexanone, which can solve the problem of using ZSM-5 catalyst Restrictions, high cost of using precious metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

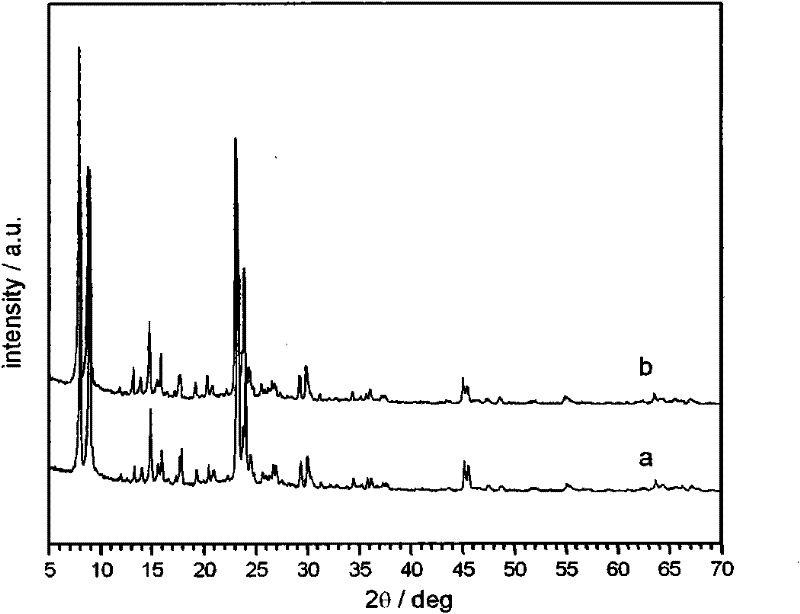

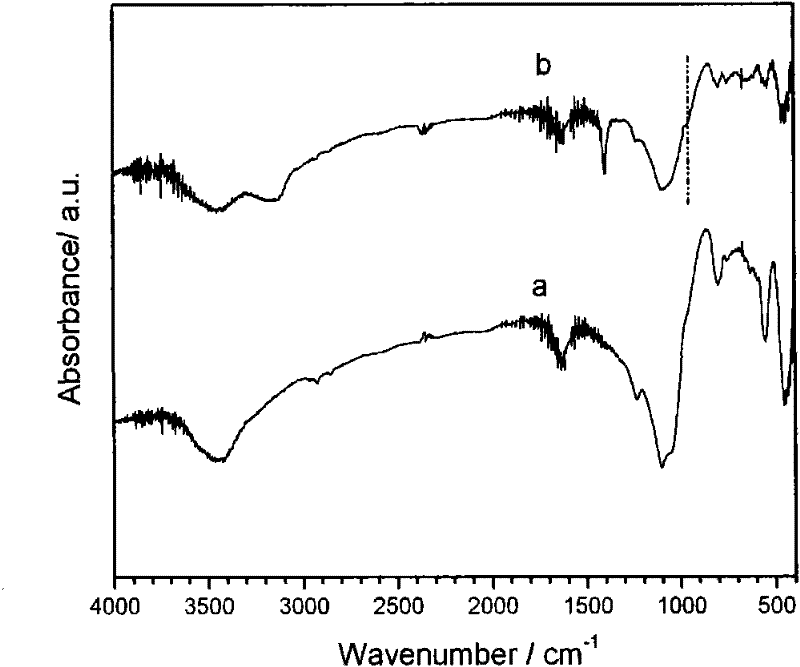

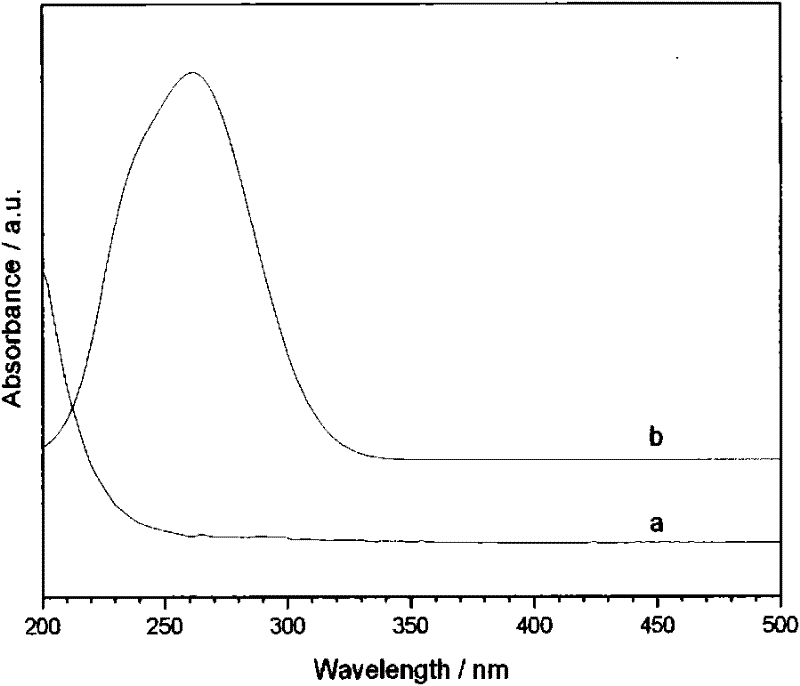

Method used

Image

Examples

Embodiment 1

[0013] After mixing the NaOH aqueous solution and white carbon black for 2h, the tetrabutylammonium bromide and NH 4 VO 3 The mixed solution is added to the above solution to form an emulsion, the pH is adjusted to 9 and stirred at room temperature for 16 hours, the molar composition of each component in the raw material is: SiO 2 : V 2 O 3 : Na 2 O: [(C 4 H 9 ) 4 N]Br:H 2 O=1:0.03:0.4:0.1:135. After stirring, the solution was transferred to an autoclave for crystallization at 180°C for 96 hours, and dried and roasted to synthesize V-ZSM-5. The catalytic oxidation reaction of cyclohexane is carried out in a 250ml autoclave equipped with a magnetic stirrer and a temperature controller. The reaction conditions are as follows: 40ml of cyclohexane and 0.15g of V-ZSM-5 catalyst are added to the reactor to react During the process, the oxygen pressure was maintained at 1.5MPa by continuous oxygenation, and the reaction temperature was 130°C. After 3 hours of reaction, the kettle was co...

Embodiment 2

[0015] After mixing the NaOH aqueous solution and white carbon black for 2h, the tetrabutylammonium bromide and NH 4 VO 3 The mixed solution is added to the above solution to form an emulsion. Adjust the pH to 10 and stir at room temperature for 16 hours. The molar composition of each component of the raw material is: SiO 2 : V 2 O 3 : Na 2 O: [(C 4 H 9 ) 4 N]Br:H 2 O=1:0.02:0.4:0.3:135, after the stirring, transfer to an autoclave for crystallization at 160C for 48h, dry and roast to synthesize V-ZSM-5. 40ml cyclohexane and 0.2g V-ZSM-5 catalyst It was added to the reaction kettle. During the reaction, the oxygen pressure was maintained at 2MPa by continuous oxygenation, the reaction temperature was 110°C, and the conversion rate of cyclohexane obtained after 4 hours of reaction was 12.19%, respectively. The selectivity of cyclohexanol and cyclohexanone was the highest. The sum is 86.2%.

Embodiment 3

[0017] After mixing the NaOH aqueous solution and white carbon black for 2h, the tetrabutylammonium bromide and NH 4 VO 3 The mixed solution is added to the above solution to form an emulsion. Adjust the pH to 11 and stir at room temperature for 16 hours. The molar composition of each component is: SiO 2 : V 2 O 3 : Na 2 O: [(C 4 H 9 ) 4 N]Br:H 2 O=1:0.01:0.4:0.2:135. After the stirring, the solution was transferred to an autoclave for crystallization at 150°C for 24 hours, and dried and roasted to synthesize V-ZSM-5. Add 40ml cyclohexane and 0.1g V-ZSM-5 catalyst to the reaction kettle, make the reaction pressure 1MPa, temperature 100℃, and react for 5 hours to obtain cyclohexane conversion rate 11.54%, cyclohexanol and cyclohexane The total selectivity of ketones is 91.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com