Cream medicine composition and preparation method thereof

A technology of composition and medicine, applied in the field of cream for treating foot fungal infection and its preparation, can solve the problems of pathogenic fungus residue, easy recurrence, poor permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

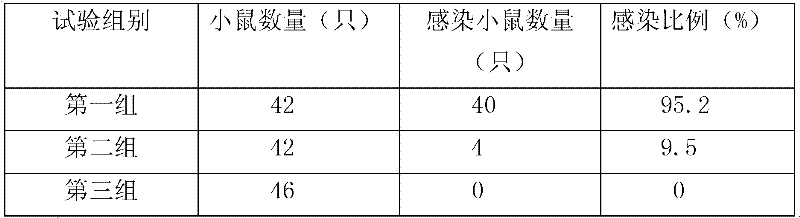

Examples

Embodiment 1

[0106] Take every 100 kg of cream as an example:

[0107] Preparation of water phase components: pump 49.35Kg of deionized water into the water phase tank and heat to 80°C. When the temperature reaches 80°C, turn on the stirring paddle, the stirring speed is 30r / min, then add 2Kg of sodium lauryl sulfate and 2Kg of fatty alcohol polyoxyethylene ether, and stir slowly to dissolve. Keep the temperature of the aqueous phase at 80°C.

[0108] Preparation of oil phase components: Add 9.0Kg of melted vaseline, 3.5Kg of stearyl alcohol, 9.0Kg of liquid paraffin, 2Kg of sorbitan monostearate, and 3.0Kg of glyceryl monostearate into the oil phase tank in sequence And laurocapram 1.0Kg. Heat to 80°C, turn on the stirring paddle, and the stirring speed is 30r / min. Maintain the substrate temperature at 80°C.

[0109] Preparation of functional components: Weigh 3.0Kg of Melaleuca alternifolia essential oil, stir and dissolve with 4.0Kg of propylene glycol, heat to 60°C and keep warm to...

Embodiment 2

[0113] Take every 100 kg of cream as an example:

[0114] Preparation of water phase components: pump 73.85Kg of deionized water into the water phase tank and heat to 80°C. When the temperature reaches 80°C, turn on the stirring paddle, the stirring speed is 30r / min, then add 1Kg of sodium lauryl sulfate and 0.5Kg of fatty alcohol polyoxyethylene ether, and stir slowly to dissolve. Keep the temperature of the aqueous phase at 80°C.

[0115] Preparation of oil phase components: Add 5.0Kg of melted vaseline, 2.0Kg of stearyl alcohol, 5.0Kg of liquid paraffin, 0.5Kg of sorbitan monostearate, and 2.0 kg of glyceryl monostearate into the oil phase tank in sequence Kg and laurocapram 0.5Kg. Heat to 80°C, turn on the stirring paddle, and the stirring speed is 30r / min. Maintain the substrate temperature at 80°C.

[0116] Preparation of functional components: Weigh 0.5Kg of Melaleuca alternifolia essential oil, stir and dissolve with 2.0Kg of propylene glycol, heat to 60°C and keep...

Embodiment 3

[0120] Take every 100 kg of cream as an example:

[0121]Preparation of water phase components: pump 28.85Kg of deionized water into the water phase tank and heat to 80°C. When the temperature reaches 80°C, turn on the stirring paddle, the stirring speed is 30r / min, then add 5Kg of sodium lauryl sulfate and 2Kg of fatty alcohol polyoxyethylene ether, and stir slowly to dissolve. Keep the temperature of the aqueous phase at 80°C.

[0122] Preparation of oil phase components: Add 12.0Kg of melted vaseline, 8Kg of stearyl alcohol, 10Kg of liquid paraffin, 2Kg of sorbitan monostearate, 6.0Kg of glyceryl monostearate and laurel into the oil phase tank in sequence Azone 2.0Kg. Heat to 80°C, turn on the stirring paddle, and the stirring speed is 30r / min. Maintain the substrate temperature at 80°C.

[0123] Preparation of functional components: Weigh 5.0Kg of Melaleuca alternifolia essential oil, stir and dissolve with 5.0Kg of propylene glycol, heat to 60°C and keep warm to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com