Acid etchant online electrolytic recycling device and etchant regenerating method

An acid etching solution and electrolytic recovery technology, which is applied in the field of raw material recovery and recycling, can solve the problems of lack of measures and methods to prevent chlorine evolution from anodes, increased difficulty in recovering copper, and increased difficulty in operation, and achieves an area of Small, easy to popularize and apply, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

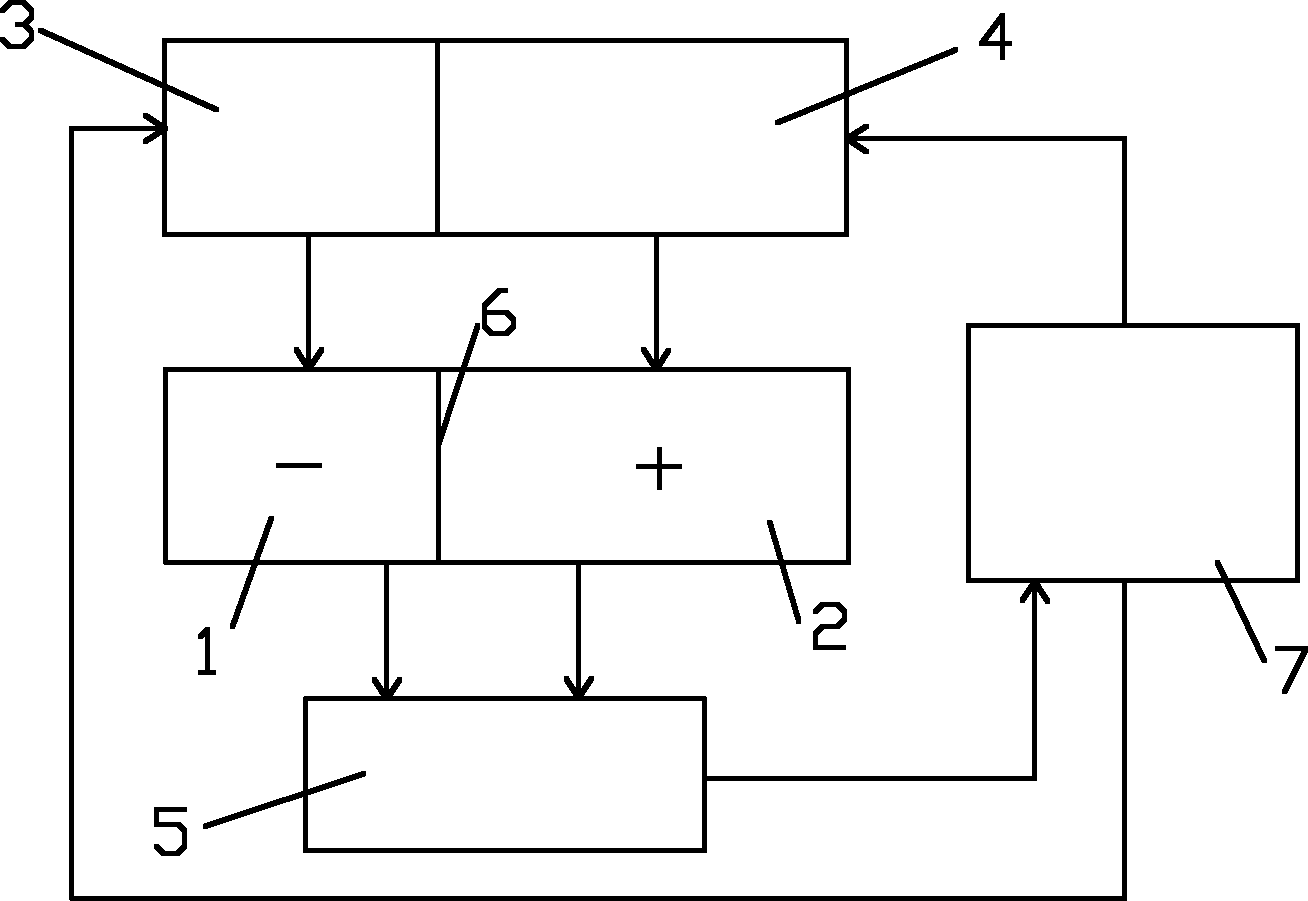

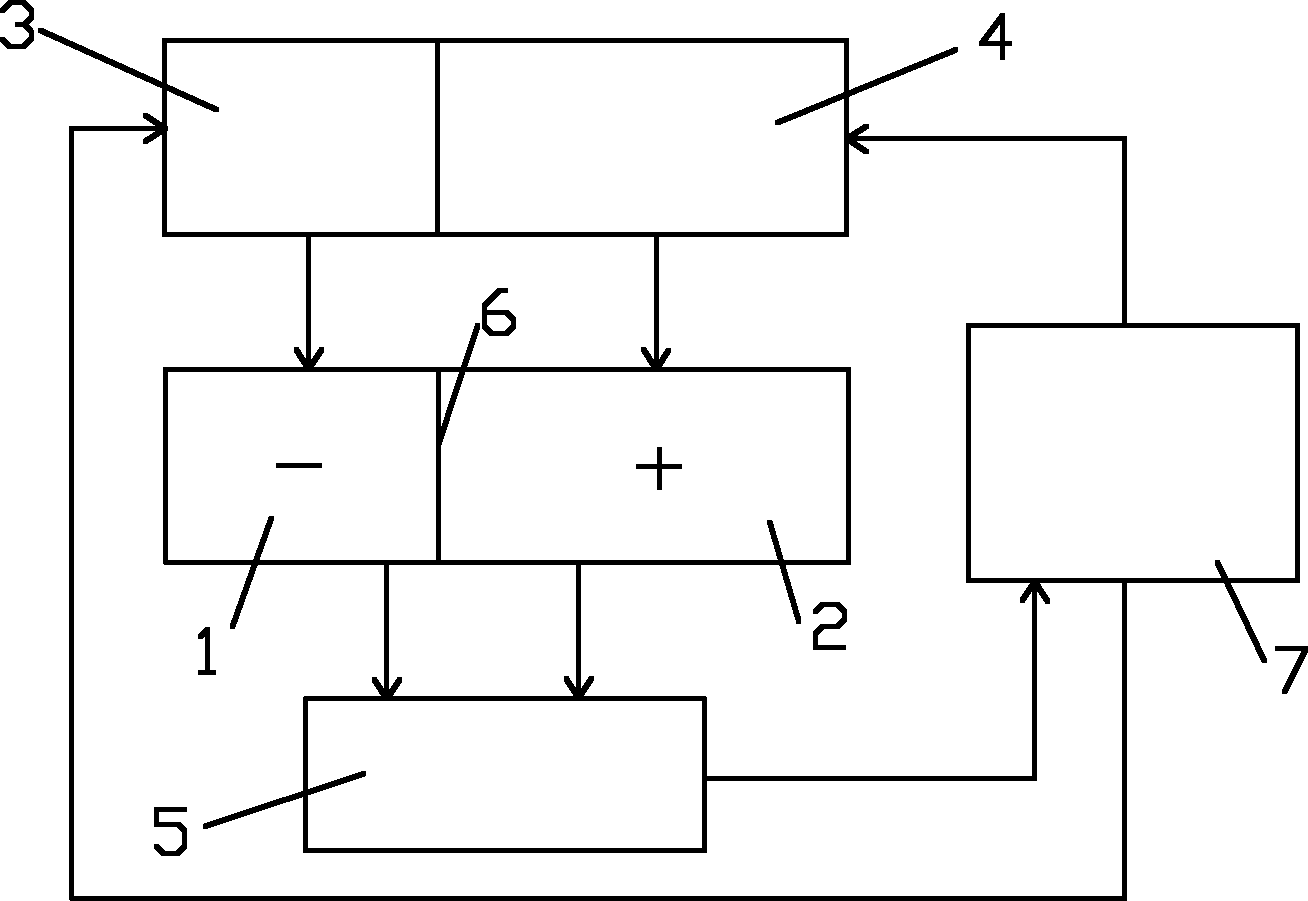

[0038] Preparation containing total copper is 175g / L (Cu + 2g / L), chlorine 270g / L, hydrogen 2.0g / L acid etching solution, used for etching machine work, such as figure 1 as shown,

[0039] (1) Before the etching begins, the acidic etching solution is imported into the electrolytic cell 6 and the adjustment tank 5, and the acidic etching solution is imported into the etching machine through the adjustment tank 5;

[0040] (2) When etching is carried out, the acid etching solution passes through the etching machine to produce etching waste liquid, and the etching waste liquid is introduced into the anolyte storage tank 4 and the catholyte storage tank 3, and the catholyte is electrolyzed in the cathode chamber 1 of the electrolytic cell to obtain the catholyte and adhere to the cathode tube The metal copper in the anode chamber 2 is electrolyzed to obtain the anolyte, and the electrolyte in the cathode chamber 1 and the anode chamber 2 of the electrolytic cell is supplemented b...

Embodiment 2

[0045] Preparation containing total copper 155g / L (Cu + 2g / L), chlorine 260g / L, hydrogen 1.9g / L acid etchant for etching machine work, such as figure 1 as shown,

[0046] (1) Before the etching begins, the acidic etching solution is imported into the electrolytic cell 6 and the adjustment tank 5, and the acidic etching solution is imported into the etching machine through the adjustment tank 5;

[0047] (2) When etching is carried out, the acid etching solution passes through the etching machine to produce etching waste liquid, and the etching waste liquid is introduced into the anolyte storage tank 4 and the catholyte storage tank 3, and the catholyte is electrolyzed in the cathode chamber 1 of the electrolytic cell to obtain the catholyte and adhere to the cathode tube The metal copper in the anode chamber 2 is electrolyzed to obtain the anolyte, and the electrolyte in the cathode chamber 1 and the anode chamber 2 of the electrolytic cell is supplemented by the catholyte st...

Embodiment 3

[0052] Preparation containing total copper 130g / L (Cu + 2g / L), chlorine 250g / L, hydrogen 1.8g / L acid etchant for etching machine work, such as figure 1 as shown,

[0053] (1) Before the etching begins, the acidic etching solution is imported into the electrolytic cell 6 and the adjustment tank 5, and the acidic etching solution is imported into the etching machine through the adjustment tank 5;

[0054] (2) When etching is carried out, the acid etching solution passes through the etching machine to produce etching waste liquid, and the etching waste liquid is introduced into the anolyte storage tank 4 and the catholyte storage tank 3, and the catholyte is electrolyzed in the cathode chamber 1 of the electrolytic cell to obtain the catholyte and adhere to the cathode tube The metal copper in the anode chamber 2 is electrolyzed to obtain the anolyte, and the electrolyte in the cathode chamber 1 and the anode chamber 2 of the electrolytic cell is supplemented by the catholyte st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com