Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

A technology of waste incineration fly ash and recovery method, which is applied in chemical instruments and methods, improvement of process efficiency, removal of solid waste, etc., can solve the problems of low added value, increased dissolution toxicity, inconvenient resource utilization, etc. Recover value, save disposal cost, harmless and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

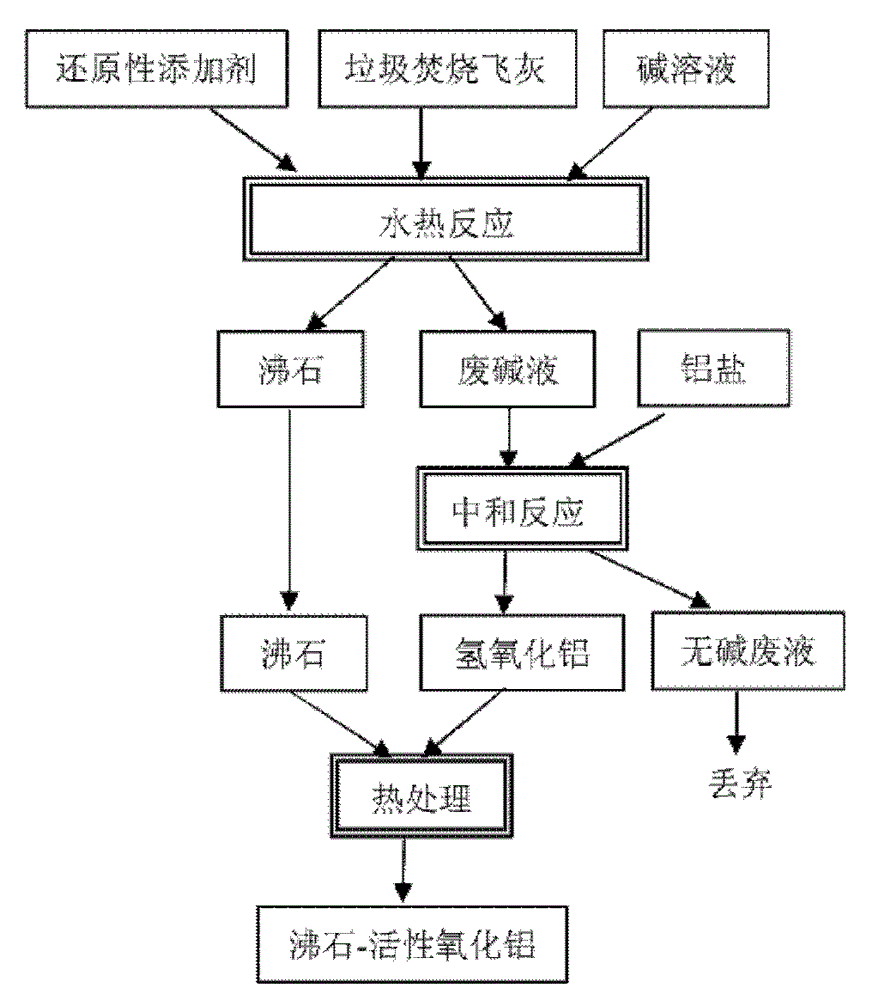

Method used

Image

Examples

Embodiment 1

[0021] The toxic equivalent of dioxin in the waste incineration fly ash produced by a municipal waste incineration plant was 6.1ngTEQ / g, and the heavy metal Pb and hexavalent chromium exceeded the toxicity leaching standard by the HJ / T300 leaching method. Using the method of the present invention, in the first step, 1M (molar concentration) NaOH solution is added to the waste incineration fly ash at a liquid-solid ratio of 6 ml / g to form an ash / NaOH solution mixed system. The second step is to add hydrazine hydrate up to 0.8% of the mass of incineration fly ash. In the third step, the reactant was heated to 230° C. under constant stirring and mixing, and kept at the reaction temperature for 5 hours, and then cooled to room temperature. The fourth step is to add AlCl with a concentration of 1M (molar concentration) while continuing to stir and mix. 3 solution until the pH reaches 8.5. The fifth step is solid-liquid separation, in which the liquid is directly discarded. The s...

Embodiment 2

[0023] The toxic equivalent of dioxin in the waste incineration fly ash produced by a municipal waste incineration plant is 3.7ngTEQ / g, and the heavy metal Pb detected by the HJ / T300 leaching method exceeds the toxicity leaching standard. Adopting the method of the present invention, in the first step, 3M (molar concentration) NaOH solution is added to the waste incineration fly ash at a liquid-solid ratio of 10 ml / g to form an ash / NaOH solution mixed system. The second step is to add hydrazine carbonate up to 0.3% of the mass of incineration fly ash. In the third step, the reactant was heated to 150° C. under constant stirring and mixing, and kept at the reaction temperature for 3 hours, and then cooled to room temperature. The fourth step is to add an Al(NO3)3 solution with a concentration of 5M (molar concentration) in the state of continuous stirring and mixing until the pH reaches 11.0. The fifth step is solid-liquid separation, in which the liquid is directly discarded....

Embodiment 3

[0025] The toxic equivalent of dioxin in the waste incineration fly ash produced by a municipal waste incineration plant is 4.5ngTEQ / g, and the heavy metals Cd and Zn detected by the HJ / T300 leaching method exceed the toxicity leaching standard. Adopting the method of the present invention, the first step is to add 2M (molar concentration) NaOH solution to the waste incineration fly ash at a liquid-solid ratio of 3 ml / g to form an ash / NaOH solution mixed system. The second step is to add hydrazine carbonate to reach 1.2% of the mass of incineration fly ash. In the third step, the reactant was heated to 95° C. under constant stirring and mixing, and kept at the reaction temperature for 24 hours, and then cooled to room temperature. The fourth step is to add Al with a concentration of 2.5M (molar concentration) while continuing to stir and mix well. 2 (SO 4 ) 3 solution until the pH reaches 9.0. The fifth step is solid-liquid separation, in which the liquid is directly disca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com