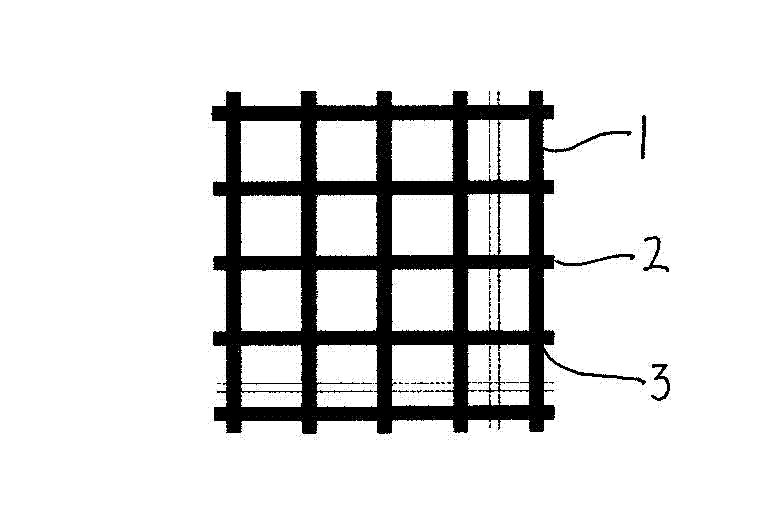

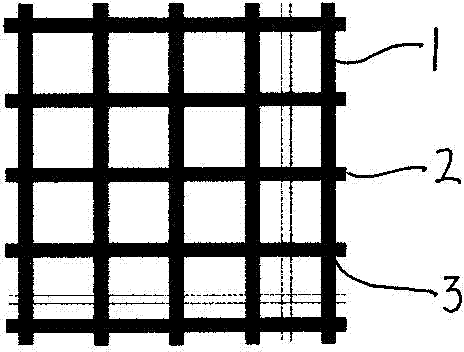

Preparation technology of high strength net false roof for underground coal mining

A preparation process and high-strength technology, used in mining equipment, earth-moving drilling, temporary shielding, etc., can solve the problems of hidden dangers of steel wire, easy to scratch staff, large mesh creep, etc., and achieve welding speed. Fast, automatic production, strong anti-corrosion and anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The first step raw material processing

[0021] Put 100 parts by weight of polypropylene, 12 parts by weight of flame retardant, and 8 parts by weight of antistatic agent into the mixer together, and control the temperature of stirring at 60 ° C, stir for 10 minutes, and leave after stirring evenly. material;

[0022] Step 2 Extrude the Strips

[0023] Fill the well-stirred mixture into the preheated plastic extruder, adjust the temperature of the barrel of the plastic extruder to keep the temperature of the barrel at 185°C, and extrude the mixture through a die head with adjusted thickness to form a high-strength mesh belt with a width of 10 mm and a thickness of 0.5 mm, and then introduce the extruded high-strength mesh belt into the cooling water tank for cooling and shaping, and the cooled and shaped high-strength mesh belt is embossed by an embossing machine and then wound to the traction on board;

[0024] The third step is welding into a mesh

[0025] Accordi...

Embodiment 2

[0029] The first step raw material processing

[0030] Add 100 parts by weight of polypropylene, 12 parts by weight of flame retardant, and 8 parts by weight of antistatic agent into the mixer together, and control the temperature of stirring at 65 ° C, stir for 5 minutes, and leave after stirring evenly. material;

[0031] Step 2 Extrude the Strips

[0032] Fill the well-stirred mixture into the preheated plastic extruder, adjust the temperature of the barrel of the plastic extruder to keep the temperature of the barrel at 200°C, and the mixture is extruded through the die with adjusted thickness , to form a high-strength mesh belt with a width of 15mm and a thickness of 1.5mm, and then introduce the extruded high-strength mesh belt into the cooling water tank for cooling and shaping. ;

[0033] The third step is welding into a mesh

[0034] According to the width and size requirements, arrange the high-strength mesh belts on the welding frame so that the vertical high-st...

Embodiment 3

[0038] The first step raw material processing

[0039] Add 100 parts by weight of polypropylene, 12 parts by weight of flame retardant, and 8 parts by weight of antistatic agent into the mixer together, and control the temperature of stirring at 62.5 ° C, stir for 7.5 minutes, and leave after stirring evenly. material;

[0040] Step 2 Extrude the Strips

[0041] Fill the well-stirred mixture into the preheated plastic extruder, adjust the temperature of the barrel of the plastic extruder to keep the temperature of the barrel at 192°C, and the mixture is extruded through the die with adjusted thickness , forming a high-strength mesh belt with a width of 12.5 mm and a thickness of 0.75 mm, and then introducing the extruded high-strength mesh belt into the cooling water tank for cooling and shaping. on board;

[0042] The third step is welding into a mesh

[0043] According to the width and size requirements, arrange the high-strength mesh belts on the welding frame so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com