Barley beta-glucan preparation method

A technology for glucan and highland barley is applied in the field of highland barley β-glucan preparation, which can solve problems such as affecting the quality of the extract and pollute the environment, and achieve the effects of easy operation, environmental protection and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

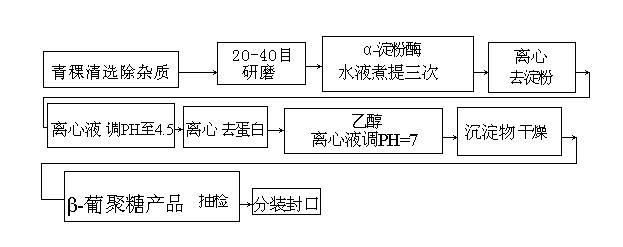

[0013] Such as figure 1 As shown, a method for preparing highland barley β-glucan of the present invention is characterized in that the method comprises the following steps:

[0014] 1) Cleaning and crushing steps: remove impurities from the highland barley grains, wash and crush them, and pass through a 20-40 mesh sieve;

[0015] 2) Extraction steps: According to the ratio of material to water 1:6~10, gelatinize in water bath at 90°C for 2 hours, add α-amylase for enzymolysis for 30 minutes, filter the filtrate according to 40 mesh, and continue to filter the residue according to the ratio of material to water 1:3~ 6. Water bath at 90°C for 2 hours, filter according to 40 mesh to obtain the second filtrate, and continue to filter the residue according to the material-to-water ratio of 1:2-4, bathe in 90°C for 2 hours, filter to obtain the third filtrate, and combine the filtrates;

[0016] 3) Centrifugal extraction step: centrifuge at 4000 rpm for 10 minutes to remove starch...

Embodiment 1

[0020] The process route of a method for preparing highland barley β-glucan of the present invention is as follows:

[0021] 20—40 mesh, add α-amylase to remove starch

[0022] Highland barley (removing impurities) → Grinding—————————————————————————————————————————————————————————→

[0023] Adjust pH to 4.5, remove protein, ethanol, dry

[0024] Centrifugate————→centrifugation———→Centrant liquid adjusted to PH=7————→ sediment———→β-glucose

[0025] Sampling

[0026] Polycane products——→Separate packaging and sealing.

[0027] The process conditions adopted in the present invention are as follows: remove impurities from the highland barley grains, wash and pulverize them, pass through a 40-mesh sieve, gelatinize in a water bath at 90°C for 2 hours, add α-high temperature resistant amylase for 30 minutes, Filtrate (40 mesh) to obtain the filtrate, continue to use the ratio of material to water 1:3, bathe in 90°C water for 2 hours, filter (40 mesh) to obtain the second filtra...

Embodiment 2

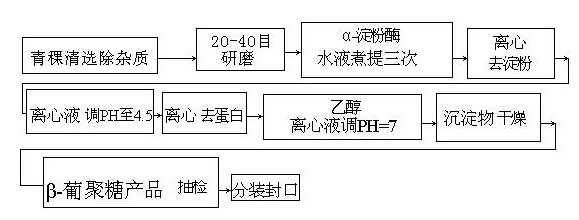

[0030] The process route of a method for preparing highland barley β-glucan of the present invention is as follows:

[0031] 20—40 mesh, add α-amylase to remove starch

[0032] Highland barley (removing impurities) → Grinding—————————————————————————————————————————————————————————→

[0033] Adjust pH to 4.5, remove protein, ethanol, dry

[0034] Centrifugate————→centrifugation———→Centrant liquid adjusted to PH=7————→ sediment———→β-glucose

[0035] Sampling

[0036] Polycane products——→Separate packaging and sealing.

[0037] The process conditions adopted in the present invention are as follows: remove impurities from the highland barley grains, wash and pulverize them, pass through a 40-mesh sieve, and use a material-to-water ratio of 1:8.

[0038] Gelatinize in water bath at 90°C for 2 hours, add α-high temperature-resistant amylase for enzymolysis for 30 minutes, filter (40 mesh) to obtain the filtrate, and continue to filter the residue according to the ratio of mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com