Fixed-point segmental cutting method and cutting device for fixed-length guide belt

A cutting device and cutting method technology, applied in metal processing and other directions, can solve the problems of manual cutting length and angle, difficult cutting, long length and other problems, and achieve the effect of avoiding metal contact on sliding surfaces, easy maintenance, and high load-bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

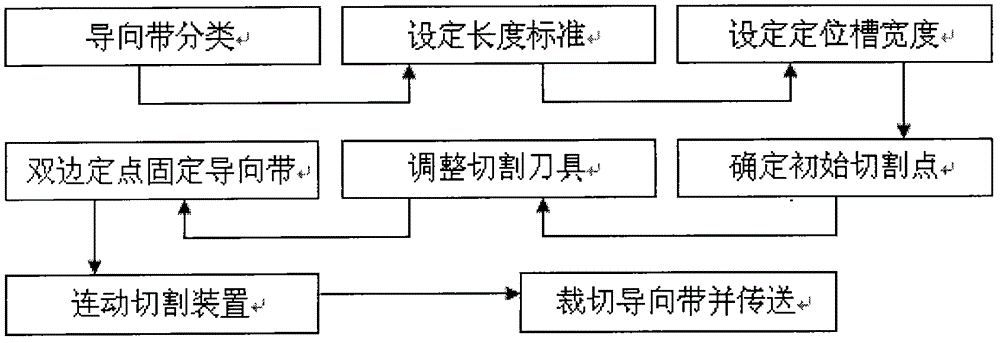

[0021] see figure 1 , a fixed-point segmental cutting method for a fixed-length guide belt, the method comprises the following steps:

[0022] (1) Guide belt cutting device is set, guide belt and guide belt length standard are set according to classification, guide belt positioning groove width is set according to the classification and length standard of the guide belt;

[0023] (2) Heating and controlling the temperature of the guide belt or directly connecting the fixing device of the guide belt cutting device to determine the initial cutting point of the guide belt;

[0024] (3) adjust the cutting tool on the guide belt cutting device according to the category of the guide belt, fix the guide belt in the positioning groove, and fix the cutting position according to the standard length bilateral fixed point;

[0025] (4) Interlocking the guide belt cutting device, cutting the guide belt with reference to the fixed point position and then transporting, until the guide belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com