Automatic forming device for refrigerator enclosing plate

A molding device and hoarding technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low efficiency, unfavorable large-scale production, and high degree of worker operation, so as to improve production efficiency, achieve continuity, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

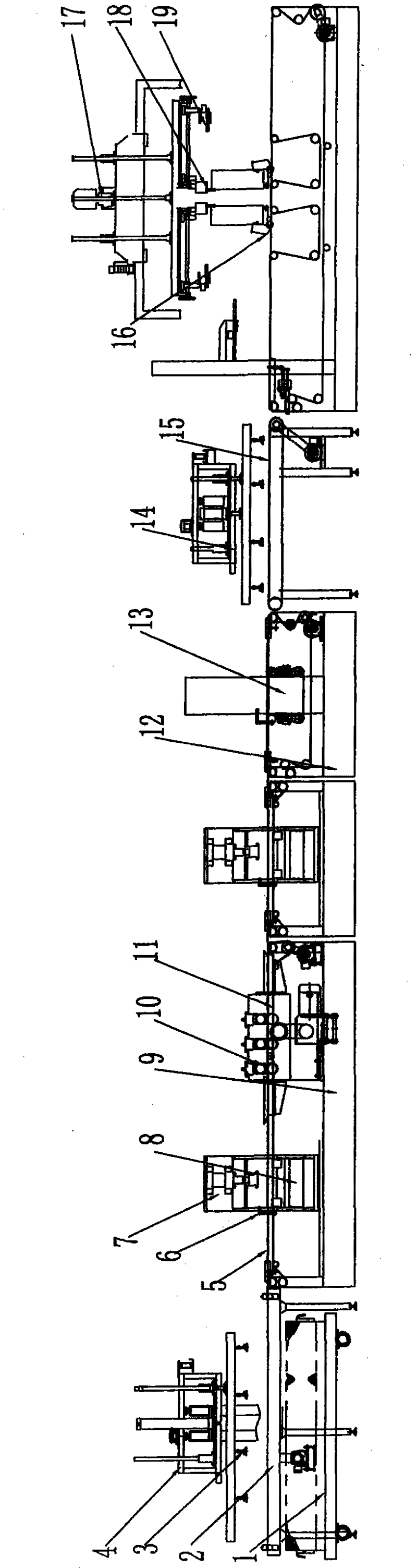

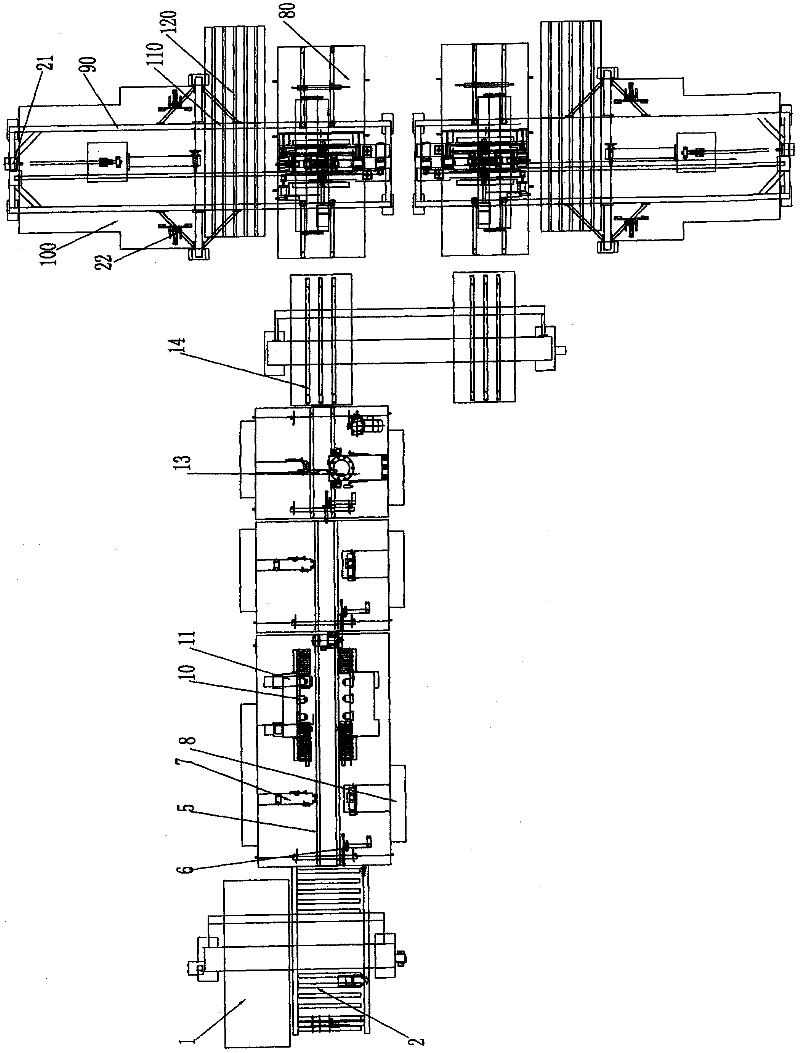

[0011] As shown in the accompanying drawings, the titles marked in the accompanying drawings of the present invention are: feeding machine 20, punching machine I30, rolling mill 40, punching machine II50, hole turning machine 60, material distribution machine 70, bending machine 80 , material transfer manipulator 90, welding machine 100, discharge manipulator 110, material receiving machine 120;

[0012] Loading trolley 1, power conveying line 2, suction cup assembly 3, conveying frame body 4, belt conveying device 5, positioning device 6, C-shaped punching die frame 7, waste collecting device 8, base 9, rolling wheel 10, gear Box assembly 11, machine base 12, C-shaped flanging formwork 13, material distribution suction cup assembly 14, belt conveyor line 15, clamping device 16, lifting device 17, horizontal clamping device 18, both sides clamping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com