Pneumatic self-locking type automatic lifting take-up device for water-tank wire drawing machine

A water tank wire drawing machine and automatic lifting technology, which is applied in the field of wire drawing machine equipment and wire drawing machine pneumatic self-locking automatic lifting and taking-up device, can solve the problems that the efficiency cannot be guaranteed, the reliability and safety are low, and the labor intensity of workers is increased. , to achieve the effect of improving efficiency, improving efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

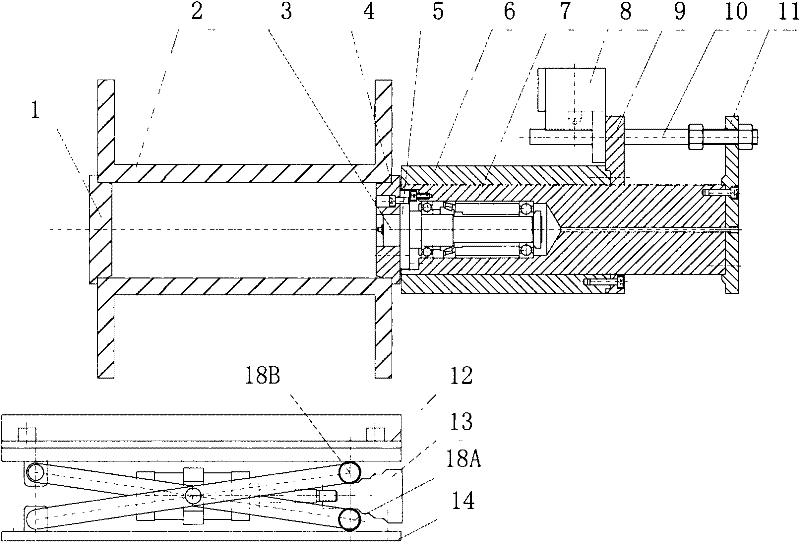

[0011] combine figure 1 , the pneumatic self-locking type automatic lifting and taking-up device of the water tank wire drawing machine of the present invention is composed of a pneumatic installation self-locking unit and an automatic lifting unit. 3. Right I-shaped wheel mounting seat 4, end cover 5, sliding seat 6, sliding sleeve 7, locking cylinder 8, rear cover plate 9, locking shaft 10, connecting plate 11, rear driving cylinder 19, front driving cylinder 20 Composition, the end of one side of the sliding seat 6 is fixedly connected with the rear cover 9, and the locking cylinder 8, the rear driving cylinder 19 and the front driving cylinder 20 are evenly distributed on the rear cover 9 along the circumferential direction of the sliding seat 6, Wherein the piston axis direction of locking cylinder 8 is perpendicular to the axis of slide seat 6, and the axis direction of rear drive cylinder 19 and front drive cylinder 20 is parallel to the axis of slide seat 6; Inside, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com