Stable sleeve-dropping method for moveable sleeve of hot milling machine

A hot-rolling mill and drop-in technology, which is applied in the direction of metal rolling, metal rolling, bending workpieces, etc., can solve the problems that cannot be controlled, unsolved, and cannot avoid the influence of rolling mill speed changes, etc., to achieve safe and accurate tracking closed-loop Effects of controlling, preventing tail flicking, and avoiding mechanical impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

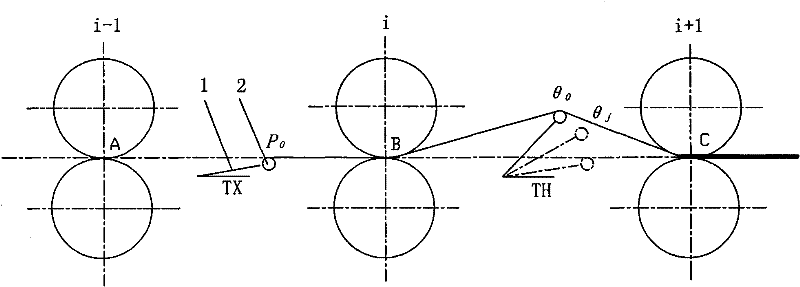

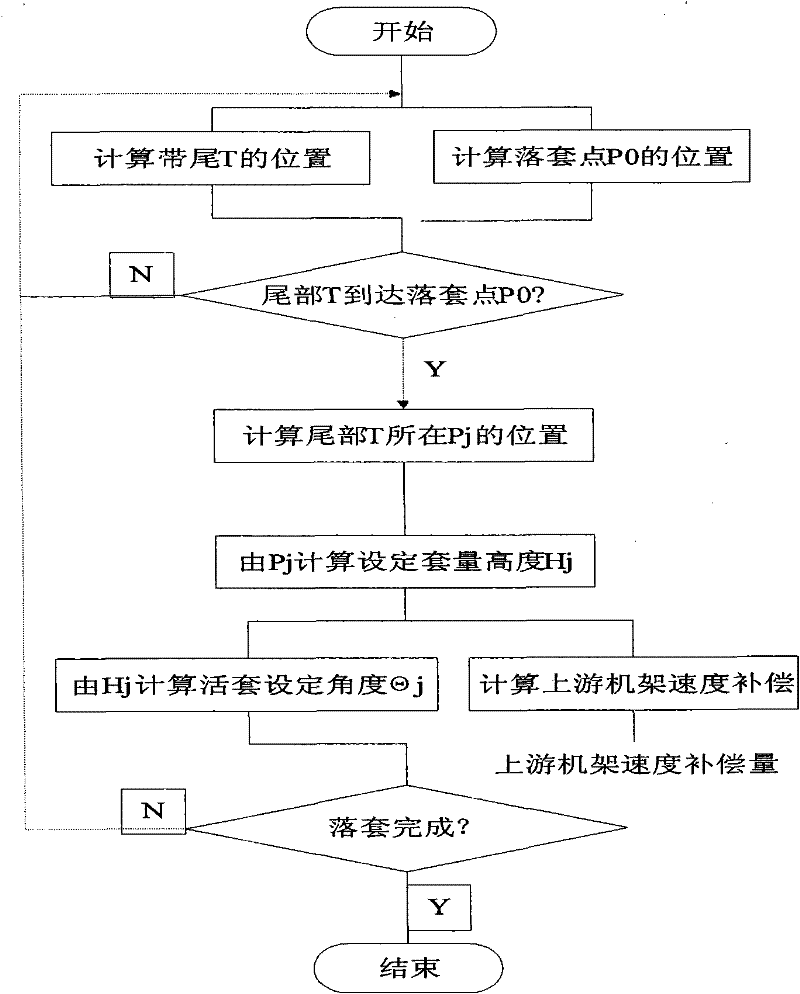

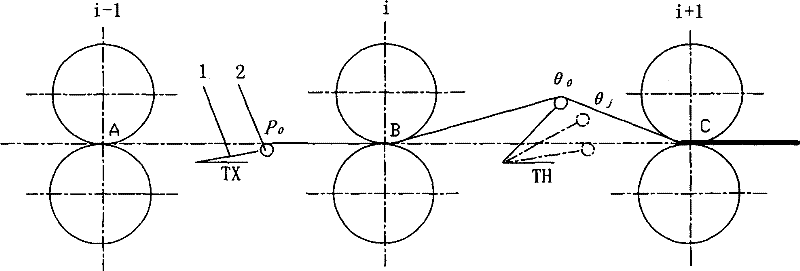

[0023] The method for the hot-rolling mill looper to fall smoothly in this embodiment is in the upstream frame i-1, the middle frame i and the downstream frame i+1 arranged in sequence, the upstream frame i+1 and the middle frame i Between them and between the intermediate support i and the downstream frame i+1, there are respectively arranged a previous looper TX and a rear looper TH which are composed of a looper rod 1 and a looper roller 2 at its end. Between the upstream frame and the middle frame and between the middle frame and the downstream frame, the strip steel tail position monitoring device is respectively installed, and the inlet A, B, and D of each frame are equipped with the entrance strip speed monitoring device respectively. The signal output terminals of the monitoring device are respectively connected to the corresponding signal input terminals of the controller, and the control output terminals of the controller are connected to the controlled terminals (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com