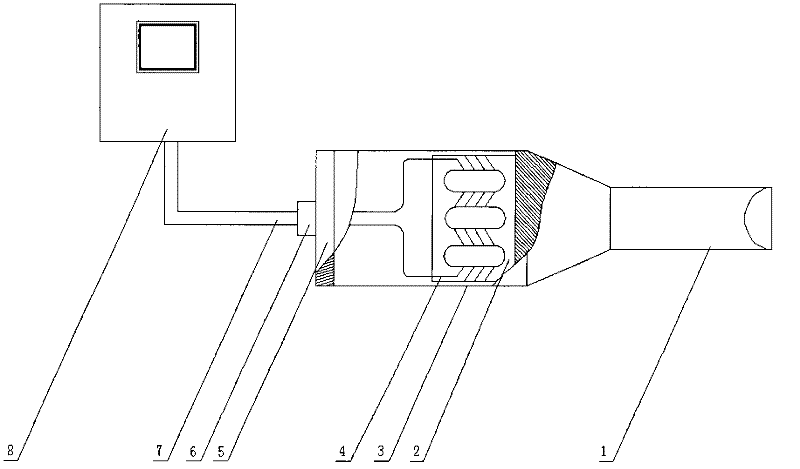

Large-power ultrasonic magnetostrictive transducer

A magnetostrictive and ultrasonic technology, applied in the direction of fluid using vibration, etc., can solve the problem of poor working performance of silicon steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] A more detailed description of the patent of the present invention: the magnetostrictive material sheet is oxidized, and the multilayer magnetostrictive material sheet is superimposed into a zigzag multilayer pure nickel block (2), and the front end is welded to the metal vibration concentrator (1) , the coil (4) is wound on the multilayer magnetostrictive material sheet, the multilayer magnetostrictive material sheet is installed in the protective shell (3), the coil lead-out shell is installed on the terminal (6), and the data line (7) , connect the controller (8). Under the action of the electric pulse signal generated by the controller (8), the zigzag-shaped multilayer magnetostrictive material sheet block (2) vibrates, and the mechanical effect produced by the vibration can emulsify liquid, liquefy gel and solid scale, etc. The role of dispersion. When the transmission medium is liquid, a large number of small bubbles can be generated. Under the action of cavitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com