Anti-freezing method for quick-frozen fresh processed meat products

A meat product, quick-frozen raw technology, applied in food preparation, application, food science and other directions, can solve the problems of nutrient loss, poor meat quality, poor product appearance and image, and achieve the effect of less water loss, bright appearance and delicious flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to better illustrate the present invention, give examples as follows:

[0009] Pre-treatment of fresh conditioned meat products, adding a certain proportion of seasonings and spices, mixing with fresh conditioned meat, adding compound additives to the rolling powder, the compound additives are: antifreeze protein, xanthan gum, white sugar and trehalose, its addition amount is antifreeze protein 0.15~0.2‰, xanthan gum: 0.3~0.5‰, white granulated sugar: 0.3~0.5%, trehalose: 0.5~1%. Amount by weight percentage. Then vacuum tumbling, after the tumbling powder is evenly wrapped on the surface of the fresh prepared meat, it is quick-frozen and packaged. Feedback from consumers after use: After thawing, the product has less water loss, high nutritional content, bright appearance and no deformation, and has a unique and delicious flavor. Antifreeze protein is commercially available

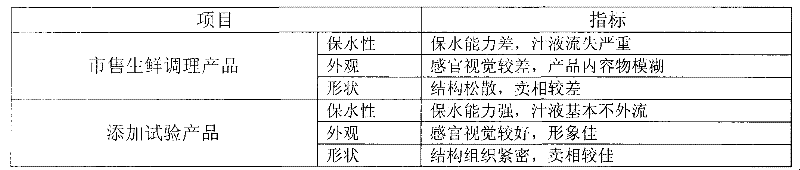

[0010] The product of the present invention is compared with the existing products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com