Dielectric wall accelerator

An accelerator and medium technology, applied in linear accelerators, accelerators, electrical components, etc., can solve the problems of pulse distortion, medium wall acceleration, acceleration gradient, etc., and achieve the effect of strong beam current, high acceleration gradient and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

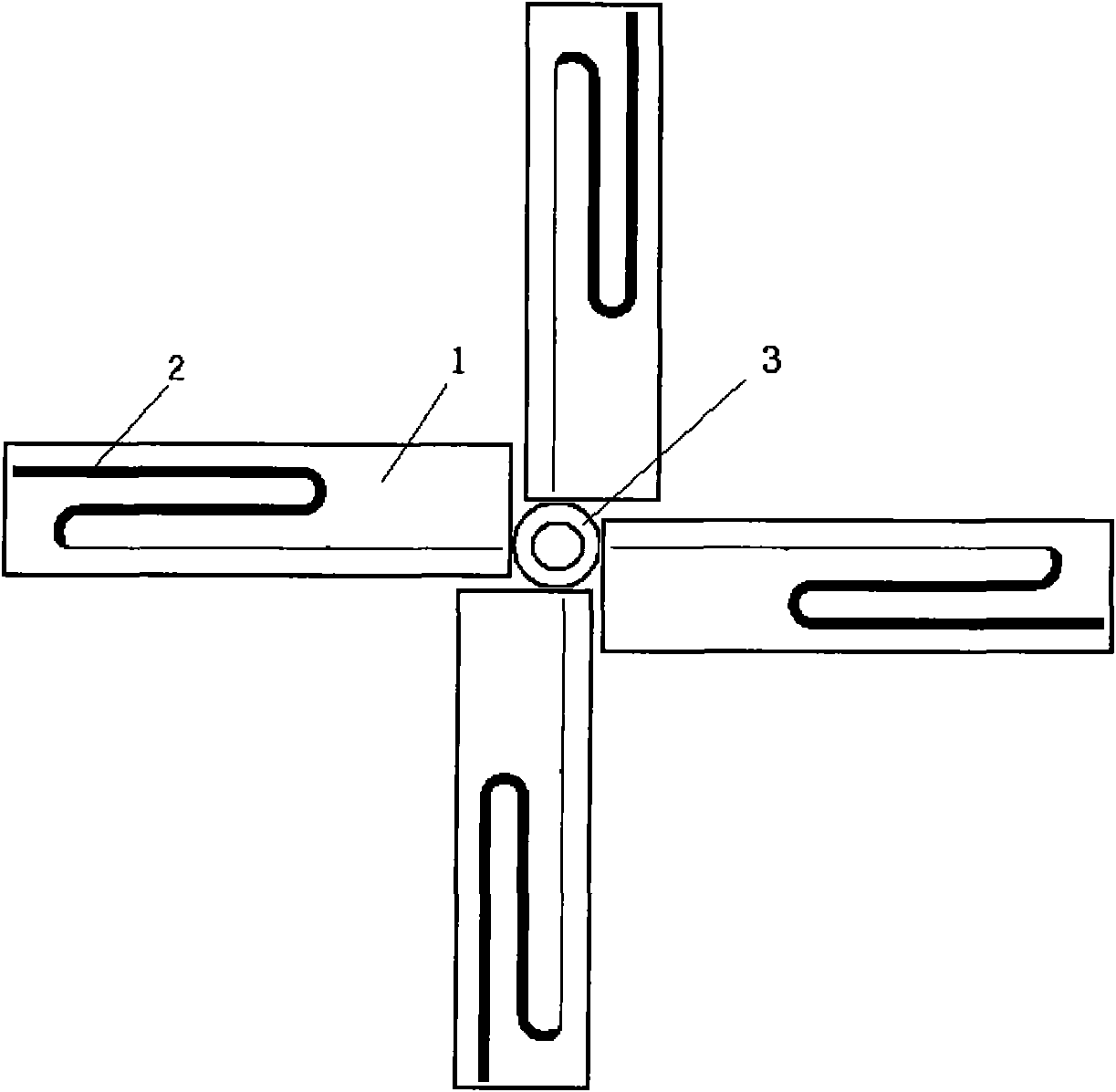

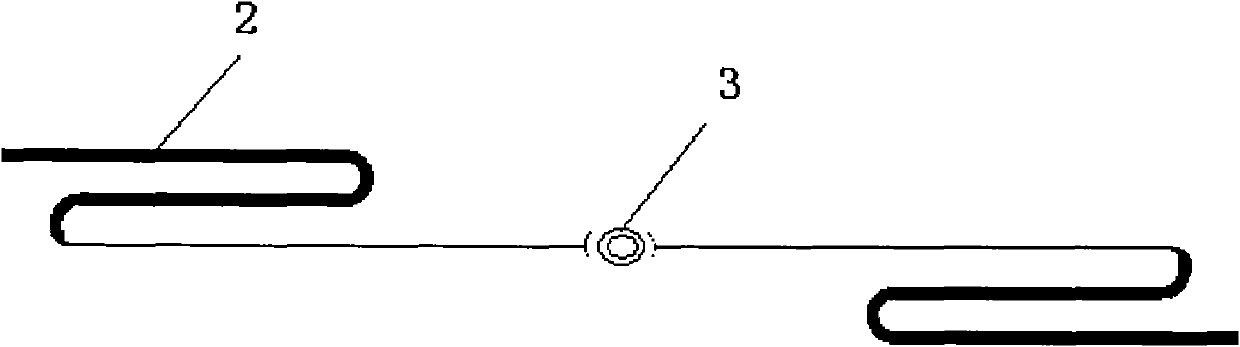

[0025] Examples of the present invention figure 1 , figure 2 As shown: the acceleration pulse forming device of a single acceleration unit is composed of four dielectric plates 1, each dielectric plate 1 is coated with metal electrodes 2 on the upper and lower sides, and a high-voltage input terminal is arranged in the middle of the dielectric plate 1, and the high-voltage input terminal is connected to one of the dielectric plates 1 A photoconductive switch is connected between the metal electrodes 2, and each layer is composed of two dielectric flat plates 1 arranged symmetrically outside the medium beam pipe 3. The magnetic field formed by the bending direction of the metal electrodes 2 on the two symmetrical dielectric flat plates 1 The same, opposite directions; the angle between the two symmetrical dielectric plates 1 on the second layer is the same as that of the first layer outside the medium beam pipe 3, and the metal electrode 2 on the dielectric plate 1 on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com