Square wound lithium ion battery and anode strip thereof

A lithium-ion battery and anode sheet technology, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc. The effect of increasing energy density, reducing redundant thickness, reducing thickness and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

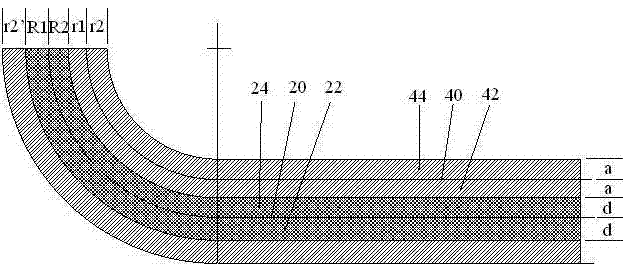

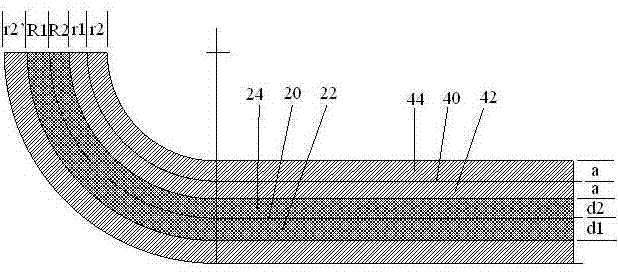

Embodiment 1

[0039] Example 1: For a wound square battery with 10 layers in the thickness direction, after adopting the optimized design of the thickness of the anode membrane of the present invention, the thickness of the outer anode membrane remains unchanged, and the thickness of the inner anode membrane is reduced to 96% of the thickness of the outer membrane. %, the thickness of each layer of membrane is reduced by 4%. According to the calculation of the thickness of a single membrane sheet of 0.070 mm, 10 layers will reduce the design thickness by 10*0.070*4%=0.028 mm, which has won valuable space for the thickness direction of the cell.

Embodiment 2

[0040]Example 2: For a wound square battery with 20 layers in the thickness direction, after adopting the optimized design of the thickness of the anode membrane of the present invention, the thickness of the outer anode membrane remains unchanged, and the thickness of the inner anode membrane is reduced to 96% of the thickness of the outer membrane. %, the thickness of each layer of membrane is reduced by 4%. According to the calculation of the thickness of a single membrane sheet of 0.075mm, 20 layers will reduce the design thickness by 20*0.075*4%=0.060 mm, which has won valuable space for the thickness direction of the cell.

[0041] In summary, the wound square lithium-ion battery of the present invention reduces the redundant thickness of the anode diaphragm by reducing the thickness of the inner anode diaphragm, and realizes effective reduction without affecting the safety performance and capacity of the battery cell. The thickness and volume of the battery core are redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com