Manufacturing method of electronic device package, electronic device package, and oscillator

A technology of electronic devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, manufacturing microstructure devices, etc., capable of solving alignment restrictions between the base substrate 41 and the cover substrate 42, the impact of product production quantity, and wafer surface bonding Solve problems such as strength deviation, achieve the effect of firm joint strength, suppress warpage, and increase charge amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

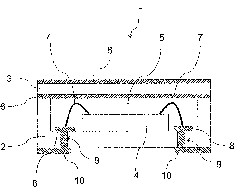

[0031] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described. Such as figure 1 and figure 2 As shown, the electronic device package 1 of the present embodiment is formed in a box shape in which two layers of a base substrate 2 and a lid substrate 3 are laminated, and is a surface mount type package in which an electronic device 4 is accommodated in an internal cavity 5 . The electronic device 4 is LSI, MEMS, a sensor, a piezoelectric vibrator, or a composite of these.

[0032] Both the base substrate 2 and the lid substrate 3 are insulating substrates made of an insulating material containing movable ions, such as soda lime glass. exist figure 1 and figure 2 In the illustrated example, a rectangular recess (cavity) 5 for accommodating an electronic device 4 is formed on the base substrate 2, and the lid substrate 3 is formed in a flat plate shape. The concave portion 5 is a concave portion that becomes a cavity 5 for housing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com