Focusing ring and substrate carrying system

A focus ring and substrate technology, applied in the focus ring field, can solve the problems of low heat conduction efficiency between the focus ring and the base, low adhesion between the focus ring and the base, and difficulty in adjusting the temperature of the focus ring, so as to prevent changes in the heating mode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

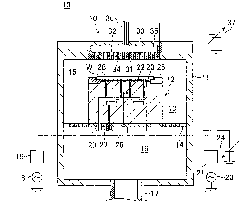

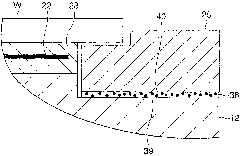

[0035] figure 1 It is a cross-sectional view schematically showing the structure of a plasma processing apparatus including a focus ring according to this embodiment. This plasma processing apparatus performs a plasma etching process on a wafer for a semiconductor device (hereinafter, simply referred to as a "wafer") as a substrate.

[0036] figure 1 Among them, the plasma processing apparatus 10 has, for example, a chamber 11 for accommodating a wafer W with a diameter of 300 mm, and a columnar susceptor 12 (mounting table) on which the wafer W for semiconductor devices is placed is disposed in the chamber 11 . In the plasma processing apparatus 10 , a side exhaust passage 13 is formed through the inner wall of the chamber 11 and the side surface of the susceptor 12 . An exhaust plate 14 is arranged in the middle of the side exhaust passage 13 .

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com