Transmitting box of cable tester

A tester and transfer box technology, which is applied to the parts, instruments, measuring electricity and other directions of electrical measuring instruments, can solve the problems of heavy workload and high precision of work, and achieve the effects of simple structure, flexible control and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

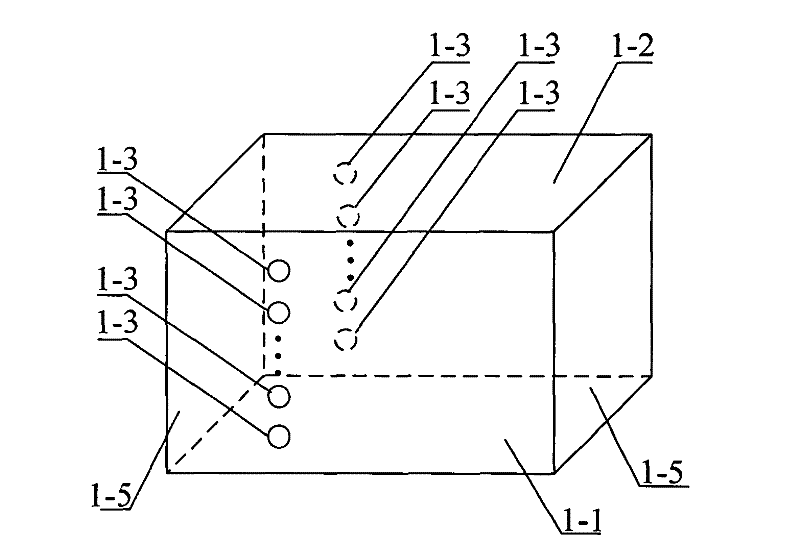

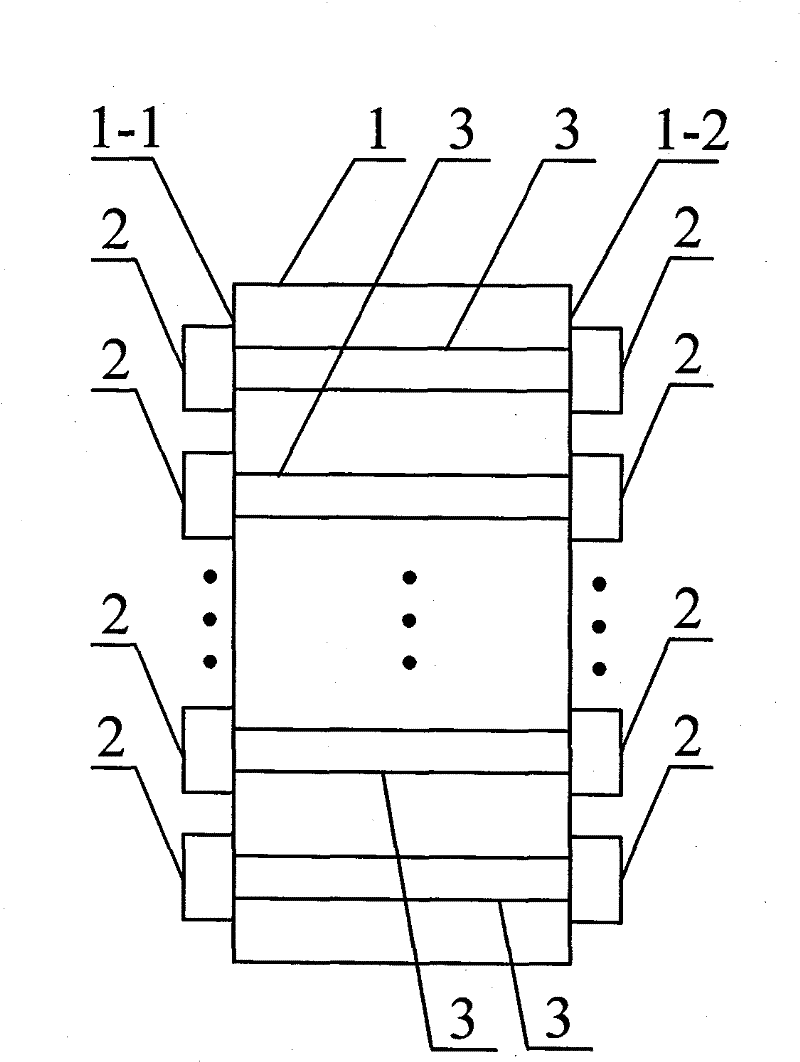

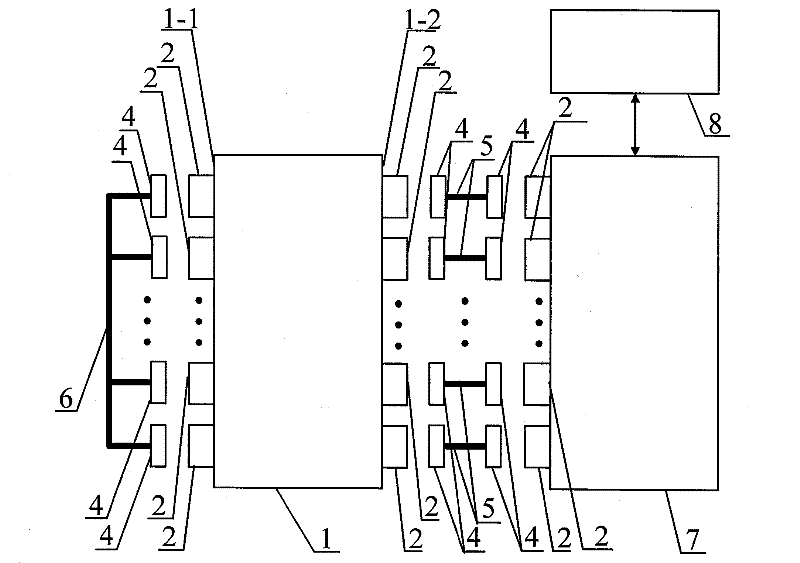

[0009] Specific implementation mode one: the following combination figure 1 , figure 2 and image 3 This embodiment will be specifically described. It includes a box body 1, and it also includes 2n fixed-end electrical connectors 2 and multi-core wires 3 with insulating separation layers. A window 1-3, the fixed-end electrical connector 2 is fixed in the window 1-3 through its fixed plate, and the conductive contacts of the fixed-end electrical connector 2 are connected with the multi-core wire with the insulating separation layer according to the pin order. The single-core wires in 3 are connected sequentially, and the n fixed-end electrical connectors 2 fixed on the front panel 1-1 and the n fixed-end electrical connectors 2 fixed on the rear panel 1-2 pass through an insulating separation layer The multi-core wires 3 are electrically connected in sequence, wherein, n is an integer greater than 1.

[0010] The mode of applying this invention to realize the connection be...

specific Embodiment approach 2

[0018] Specific implementation mode two: the following combination Figure 4 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the n fixed-end electrical connectors 2 fixed on the front panel 1-1 are divided into m fixed-end electrical connector arrays 9, and each fixed-end electrical connector array 9 consists of It consists of i fixed-end electrical connectors 2 of the same type, wherein m is an integer greater than 1 and less than n, and i is an integer greater than 1 and less than n.

[0019] The application of this embodiment can realize the simultaneous connection of multiple cables on a cable tester transfer box, which facilitates rapid switching between different cables during cable testing.

[0020] In this embodiment, different fixed-end electrical connector arrays 9 can also integrate different types of fixed-end electrical connectors 2 as required,

[0021] In this way, the integration of various types...

specific Embodiment approach 3

[0022] Specific implementation mode three: the following combination Figure 5 This embodiment will be specifically described. The difference between this embodiment and Embodiments 1 and 2 is that it also includes a middle panel 1-4, which is parallel to the two side panels 1-5 and fixed inside the box body 1.

[0023] The box body in this embodiment is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com