Four-screen accuracy target structure assembling and parameter measuring method

A technology of parameter measurement and four light curtains, which is applied in the structure adjustment and parameter measurement of four light curtain precision targets, and in the field of projectile shooting density measurement device adjustment, which can solve the problems of large measurement errors and achieve relaxation of processing and installation accuracy required effect

Inactive Publication Date: 2011-09-21

XIAN TECH UNIV

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides a structure adjustment and parameter measurement method of a four-light-curtain precision target to overcome the problem of large measurement errors caused by inaccurate structural parameters in the installation and actual use of the existing four-light-curtain precision target

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

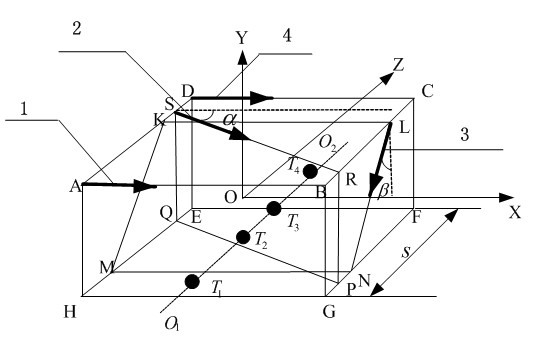

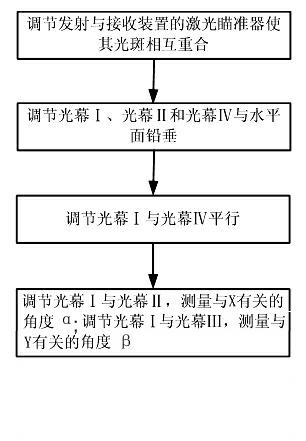

The invention relates to a four-screen accuracy target structure assembling and parameter measuring method, aiming at solving the problem of large measured error due to inaccurate structure parameters in assembly and practical use of the conventional four-screen accuracy target. The method adopts a technical scheme comprising the following steps of: (1) adjusting a laser sight of a transmitting and receiving device to ensure speckles of the laser sight are superposed; (2) adjusting to ensure that a light screen I, a light screen II and a light screen IV are vertical to the plane, and the light screen I is parallel to the light screen IV; and (3) adjusting the light screen I and the light screen II to measure an angle alpha related to X, and adjusting the light screen I and a light screen III to measure an angle beta related to Y. By adopting the method, a virtual reference plane is constructed by adopting two laser levels, reference or three mutually-vertical external reference planescan be prevented from being set or constructed on a mechanical structure, namely a hexahedral support structure, so that the requirement for processing and assembling accuracy of the hexahedral support structure is relaxed. The measured structure parameters are accurate by adopting the method, so that measurement errors are avoided.

Description

Four light curtain precision target structure assembly and parameter measurement method technical field The invention belongs to the technical field of ballistic parameter testing outside the shooting range, and mainly relates to an adjustment method of a projectile shooting density measurement device, in particular to a structure adjustment and parameter measurement method of a four-light curtain precision target. Background technique Standing target shooting density is an important indicator to measure the performance of low-elongation ballistic weapons. The traditional density measurement mostly adopts contact measurement. Materials such as wood board, cardboard or textile cloth are vertically erected at the predetermined measurement position along the ballistic trajectory. A target, The weapon being evaluated shoots at the target, and the accuracy of the weapon is judged by manually measuring the position of the bullet hole on the target. This method has low measuremen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F41J5/02

Inventor 安莹倪晋平冯斌高芬鲁倩武志超孟祥众

Owner XIAN TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com