Gear-driven internal combustion engine

A gear transmission mechanism and gear transmission technology, applied in the direction of transmission devices, machines/engines, friction transmission devices, etc., can solve the problem of low power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

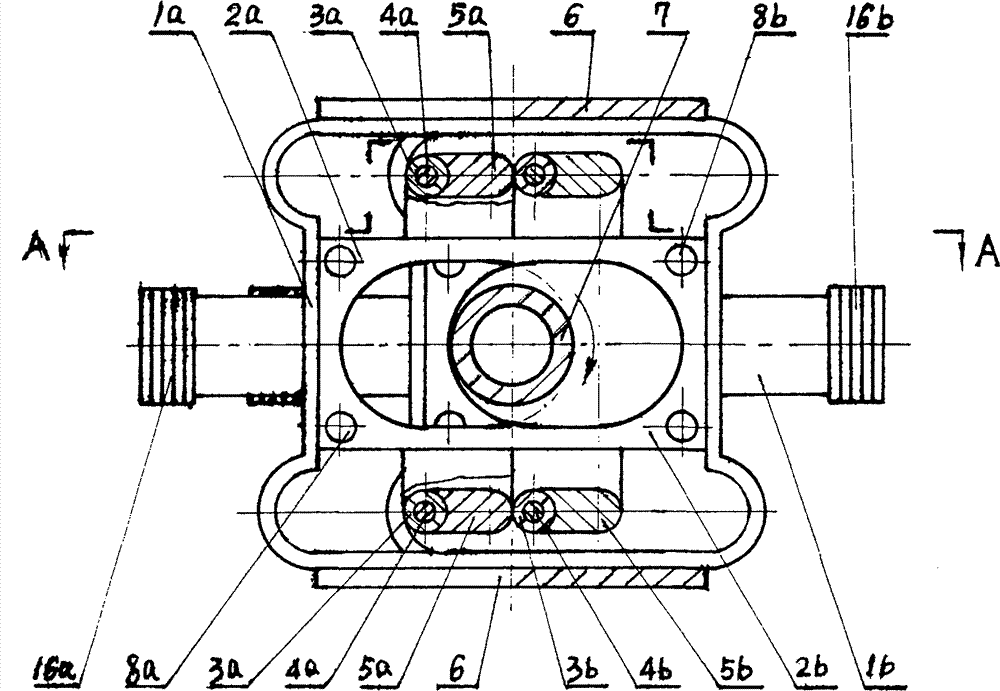

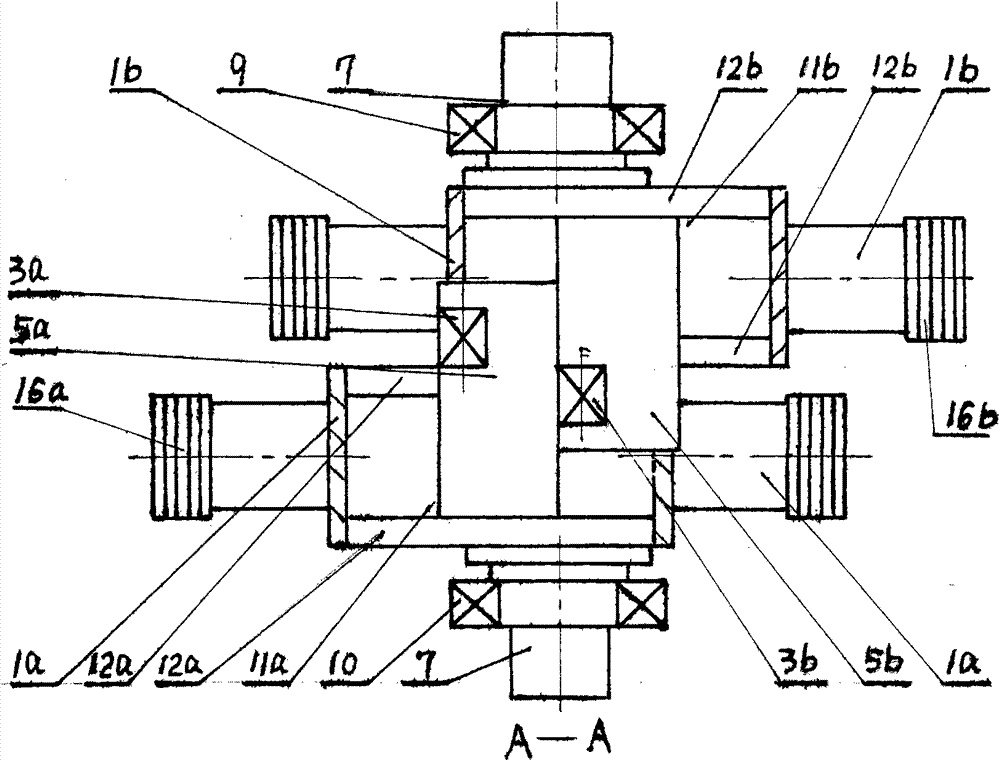

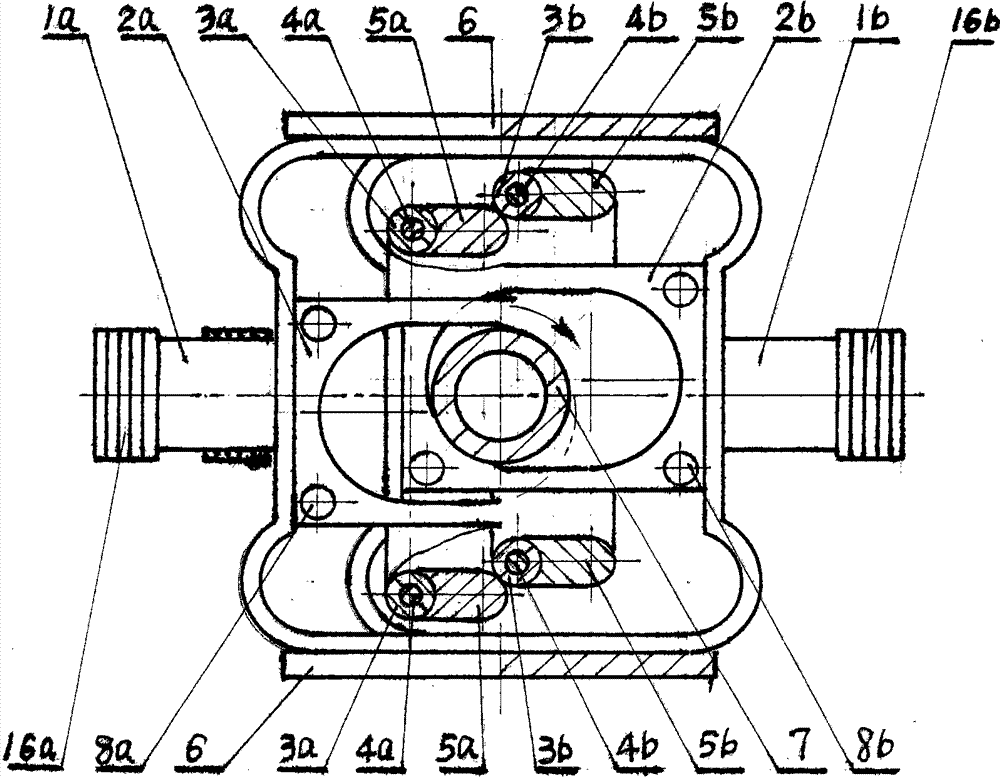

[0039] Embodiment 1: 1.6 liters of four-cylinder four-stroke gear transmission internal combustion engine, see Figure 1 to Figure 7 .

[0040] The bore of the internal combustion engine is 81mm, the stroke is 77.1mm, and the displacement is 1589cc. Such as Figure 7 As shown, the cylinder head of the internal combustion engine adopts a thin design, so that the width of the horizontally opposed internal combustion engine is controlled at 800mm. Most car engine compartments have a width of 900mm and have installation space. If the engine is mounted longitudinally so that the piston moves in the same direction as the car runs, the car will run more smoothly.

[0041] After more than one hundred years of development, the technology of internal combustion engines for vehicles has been very mature. In order to inherit all the advanced technologies and scientific research achievements of modern internal combustion engines, the gear transmission mechanism of the present invention...

Embodiment 2

[0045] Embodiment 2: gear transmission hydraulic motor.

[0046] Such as figure 1 As shown, the piston of the gear transmission mechanism is equipped with a hydraulic cylinder and a reversing valve, which can push the transmission shaft [7] to rotate under the action of pressure oil. The output effective power is high and the output torque is large.

Embodiment 3

[0047] Embodiment 3: gear transmission pump.

[0048] Such as figure 1 As shown, the gear transmission mechanism is driven by the prime mover to rotate the transmission shaft [7], which drives the piston to make a reciprocating linear motion, and sucks and pumps the medium in the cylinder through the one-way valve group.

[0049] Practical example 4, ideal geared internal combustion engine, see Figure 8 to Figure 11 .

[0050] The gear sleeve assembly [2a] and the gear sleeve assembly [2b] of an ideal geared internal combustion engine are the same, and the shape of the internal gear is a rectangle with four rounded corners, and the index circles of the two opposite quarter internal gears The pitch circle radius of the gear on the radius and transmission shaft [7] is equal. As mentioned earlier, the shape of the hub is the same as the centerline outline of the teeth of the internal gear. The shape of positioning slide block [15a] and positioning slide block [15b] is equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com