Turbine device with variable flows

A flow and turbine technology, used in gas turbine devices, engine components, machines/engines, etc., can solve problems such as poor reliability and low efficiency, and achieve the effects of good inheritance, simple volute structure, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

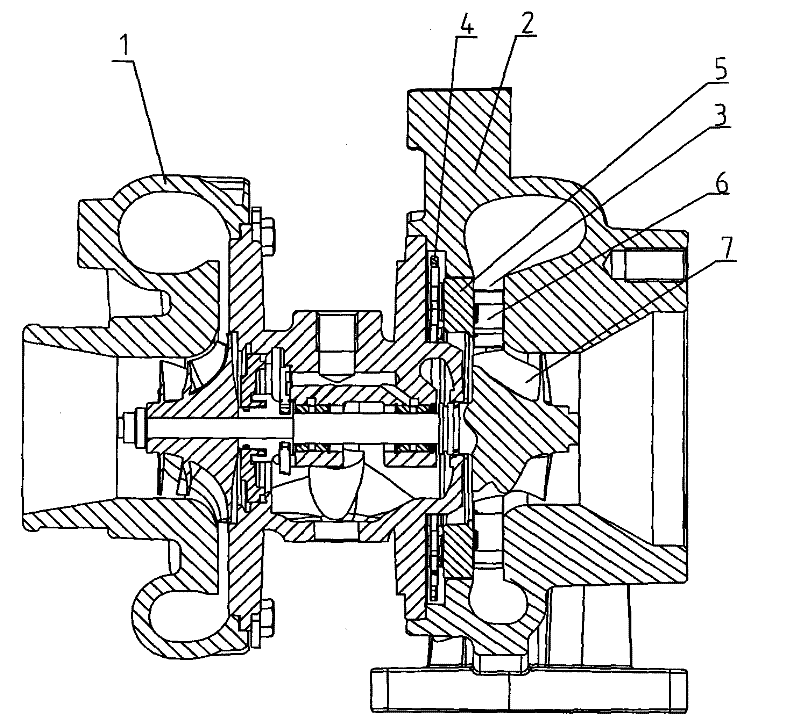

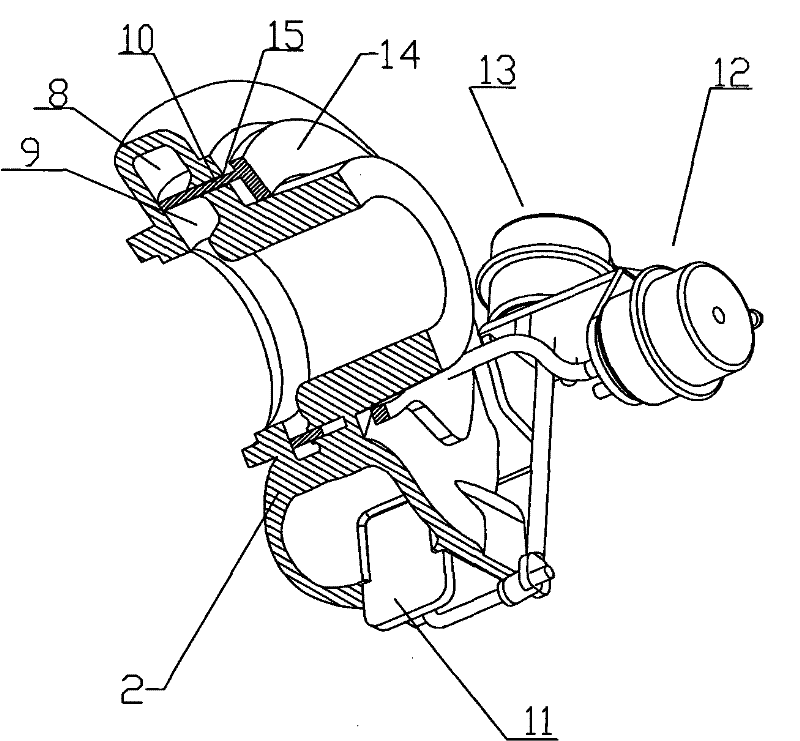

[0055] Embodiment 1, as attached figure 2 And attached image 3 As shown, a variable flow turbine device includes a volute 2, and the volute 2 is provided with an air intake channel; the air intake channel is provided with a partition wall 19 and a movable baffle with an arc-shaped transverse section. 10. The moving baffle 10 can move axially along the volute 2 in the air intake passage; one end of the moving baffle 10 protrudes from one side of the volute 2 and is connected with a moving baffle control device 12; when moving When the other end of the baffle 10 moves to the other side of the volute 2 , the moving baffle 10 separates the volute 2 into a volute outer flow channel 8 and a volute inner flow channel 9 that do not communicate with each other.

[0056] The volute outer channel 8 and the volute inner channel 9 are arranged in parallel, and the transverse section of the movable baffle 10 is straight.

[0057] A sliding slot 15 is provided on the volute 2 at a positi...

Embodiment 2

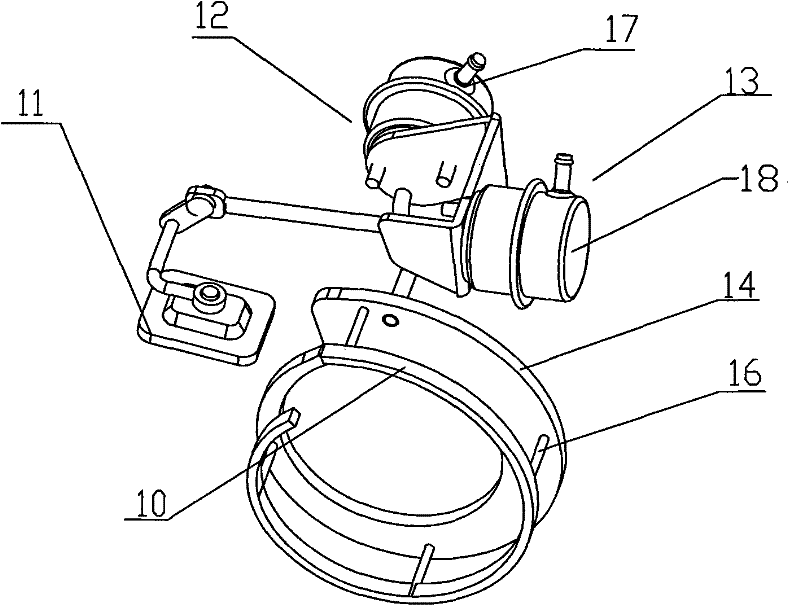

[0067] Embodiment 2, the difference between this embodiment and embodiment 1 is that, as Figure 6 As shown, the volute outer flow channel 8 and the volute inner flow channel 9 are arranged alternately. 20 is arranged longitudinally, the transverse section of the moving baffle 10 is a straight plate type, the moving baffle 10 is perpendicular to the flow channel vent 20, and is used to separate the volute outer flow channel 8 and the volute inner flow channel 9, and the moving baffle plate Under the action of the control mechanism, it can move along the axial direction of the volute, so as to realize the selection of different flow channels in the volute and the control of the gas flow distribution. According to the different shapes of the volute, the position and shape of the movable baffle 10 and its control mechanism can be designed specifically to meet the requirements of the variable channel of the volute.

Embodiment 3

[0068] Embodiment 3, the difference between this embodiment and embodiment 2 is that Figure 7 As shown, the transverse section of the movable baffle 10 is L-shaped, and the cross-sectional width A of the bottom transverse part is greater than or equal to the cross-sectional width B of the vertical part. 20 is opened, so that the gas in the outer channel 8 of the volute flows into the inner channel 9 of the volute under the guidance of the moving baffle 10, reducing the velocity component in the axial direction of the gas flowing into the inner channel 9 of the volute, and reducing the connection with the volute The blending of the airflow in the inner runner 9 reduces flow loss, improves the efficiency of the turbine, and can reduce the radial size of the turbine, which is beneficial to the installation of the turbine on the engine.

[0069] Under the action of the movable baffle control mechanism, the movable baffle 10 can move along the axial direction of the volute, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com