Equipment and method for preparing high-purity directionally crystallized polysilicon

A technology of directional crystallization and polysilicon, applied in polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve problems such as crucible material pollution, achieve low cost, reduce production cost, and solve the difficult effect of waterway design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention also proposes a preparation method for preparing high-purity directional crystal polysilicon with the above-mentioned equipment, which includes the following steps:

[0081] Step 1: Preparatory work: raise the crucible bottom 24 of the cold crucible 2 to the lower part of the cold crucible 2, seal the lower opening of the cold crucible 2, then add the metal silicon raw material to be purified into the cold crucible 2, to accommodate the cold crucible Vacuumize the vacuum chamber 1 of 2, and fill the vacuum chamber 1 with high-purity inert gas, such as high-purity argon with a purity of not less than 99.999%, after the vacuum degree reaches the requirement;

[0082] Step 2: Start the heating and melting process: In order to carry out the directional solidification process, the induction power supply must first be activated to deliver high-frequency current to the main inductor 3 surrounding the cold crucible 2 and generate an electromagnetic field in...

Embodiment 1

[0088] Embodiment 1 is an example of preparing polysilicon.

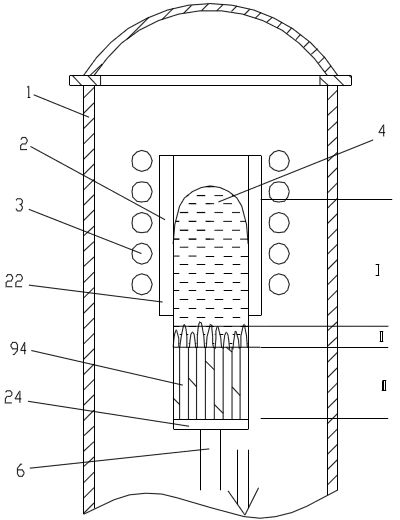

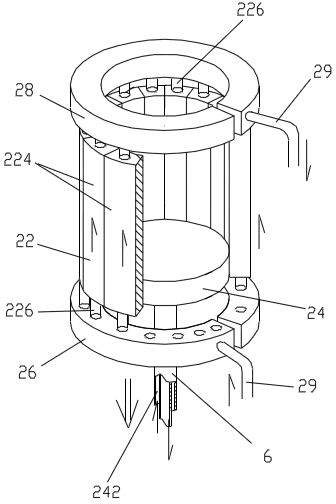

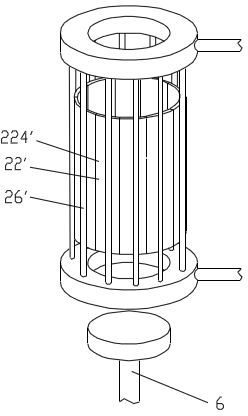

[0089] Vacuum chamber 1 is made of stainless steel ( figure 1 ), inner diameter 600mm, height 2.5m. The internal diameter of cold crucible 2 is 200mm, and height is 800mm ( image 3 ). The crucible wall is divided into 22 parts and 24 petals, and the outer surface is welded with copper tubes for water cooling. A movable crucible bottom 24 is mounted on the lower end of the crucible wall 22 . The power supply is 350kw and the frequency is 10kc. It is connected to the main inductor 3 surrounding the cold crucible 2 .

[0090] The crystallization zone is located in the section of the auxiliary inductor 46 at 20 mm below the lower end of the crucible wall 22 ( Figure 5 ). The auxiliary inductor 46 has an inner diameter of 210mm and a height of 100mm, which is connected with an auxiliary power supply with a power of 60kw and a frequency of 400kc. The high-frequency electromagnetic field in the crystallization zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com