Diamond honing oil stone for processing reticulate patterns on platform of cylinder sleeve and preparation method thereof

A technology for platform reticulation and honing whetstone, applied in the field of diamond honing whetstone and its preparation, can solve the problems of different widths, different depths of reticulation, failure to meet relevant indexes of cylinder liner, etc., and achieve the effect of not falling off easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0021] The present embodiment contains according to its weight percentage: CuSn10 bronze powder 62%, iron powder 15%, nickel powder 15%, artificial diamond concentration 8%, artificial diamond grain size 200 orders; Will be used as the material for preparing metal bond CuSn10 bronze powder, iron powder, nickel powder and diamond are mixed in a three-dimensional mixer according to the ratio for 1 hour; the mixed raw materials are pressed in two directions by powder metallurgy in a cold-work die steel mold, and the pressing pressure is 30Mpa; Vacuum hot pressing is carried out in a high-strength graphite mold, where the hot pressing temperature is 700°C, the hot pressing time is 4 minutes, the pressing pressure is 3Mpa, and the vacuum degree is 1×10 -3 Pa

Embodiment 3

[0023] The present embodiment contains according to its weight percentage: 70% of CuSn10 bronze powder, 5% of iron powder, 15% of nickel powder, 10% of artificial diamond concentration, and 320 orders of artificial diamond particle size; will be used as the material for preparing metal bond CuSn10 bronze powder, iron powder, nickel powder and diamond are mixed in a three-dimensional mixer according to the ratio for 1 hour; the mixed raw materials are pressed in two directions by powder metallurgy in a cold-work die steel mold, and the pressing pressure is 30Mpa; Vacuum hot pressing is carried out in a high-strength graphite mold, where the hot pressing temperature is 750°C, the hot pressing time is 3 minutes, the pressing pressure is 4Mpa, and the vacuum degree is 1×10 -3 Pa.

[0024] Use effect of the present invention is as follows:

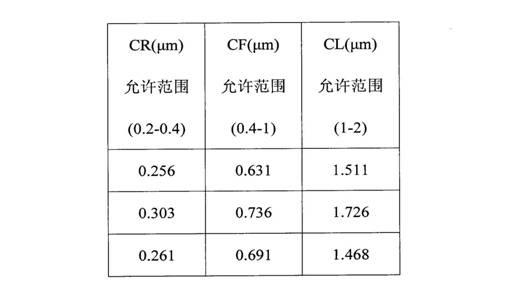

[0025] The above-mentioned honing oil stone is processed on a Z4-600-125 Gehring honing machine to process the cylinder liner, and the textur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com