Reinforced stress shot blasting method and device

A shot blasting device and stress technology, used in abrasives, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of insufficient stress relief, low product quality, poor surface quality, etc., and achieve the effect of sufficient stress relief.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

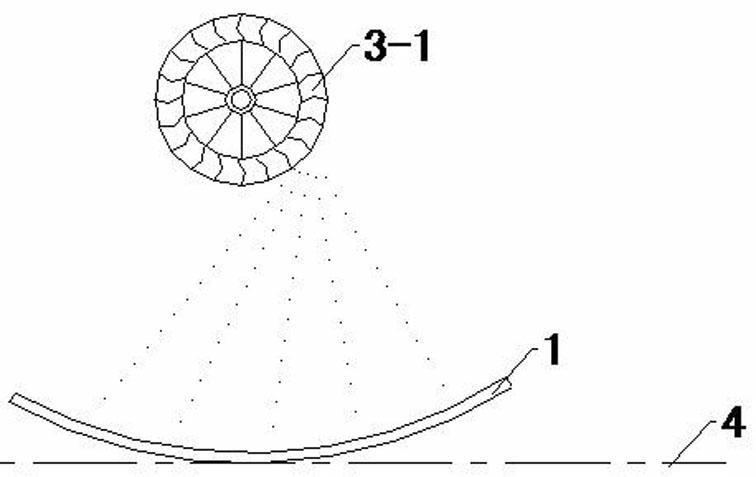

[0013] Shot blasting is to throw steel shots onto the surface of the leaf spring 1 at a high speed and a certain angle by mechanical means, so that the surface layer undergoes plastic deformation and forms a strain layer, and changes in the structure and residual stress occur in the strain layer , reasonable control of these changes within the strain layer can improve the fatigue fracture and stress corrosion cracking of the leaf spring.

[0014] The existing free shot peening method is: under the condition of neither restricting the position of the leaf spring 1 nor applying prestress, steel balls are projected onto the leaf spring 1, and the stress of the leaf spring 1 processed by this method is eliminated. Inadequate, low quality product.

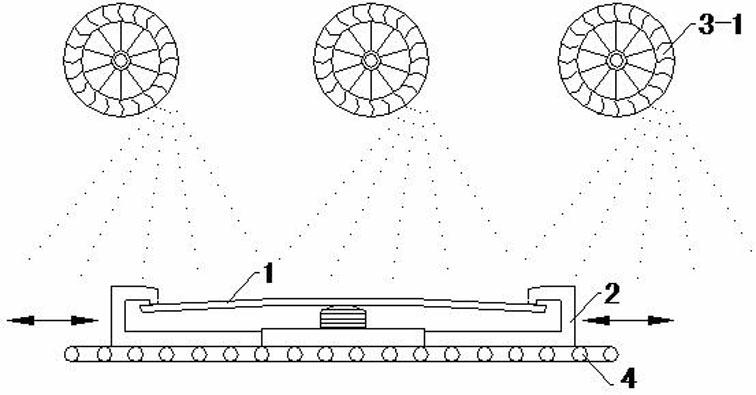

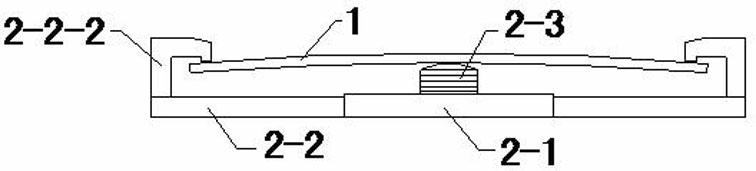

[0015] In view of the aforementioned problems, the present invention proposes a stress-strengthening shot blasting method, which uses a clamp 2 to clamp the leaf spring 1, so that the leaf spring 1 undergoes directional bending, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com