Novel strongly and weakly alkaline anion exchange resin and preparation method thereof

A technology of exchange resin and anion, which is applied in the field of ion exchange resin preparation technology, can solve the problems of strong and weak base resin synthesis and less application, and achieve the effect of large exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

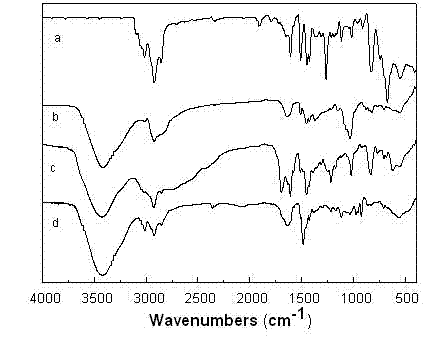

[0024] Add 15g of macroporous chloromethylated polystyrene resin to a 250mL four-necked flask equipped with a stirrer, a spherical condenser, and a thermometer, swell with 100mL of absolute ethanol for 8 hours, and then add 3 times the amount (molar ratio) of diethanolamine 25mL, heated up to 50°C, and reacted for 18h. Pour out liquids such as ethanol, add 100mL of 1mol / L sodium hydroxide solution, stir at room temperature for 2h, pour out the liquid, wash with water until neutral, and reflux extract with absolute ethanol for 24h. Vacuum dry. Resin I was obtained with the following structural formula. Its infrared spectrum is as figure 1 .

[0025] .

[0026] Add 5.0g of resin Ⅰ to a 100mL four-necked flask equipped with a stirrer, spherical condenser and thermometer, add 30mL of benzene dried over magnesium sulfate for 48 hours, and 5mL of pyridine dried over anhydrous potassium carbonate, and swell for 6 hours under ice-water bath conditions. 25mL of thionyl chloride ...

Embodiment 2

[0029] The steps for preparing resin II are the same as in Example 1.

[0030] Add 1g of resin II, 50mL of DMF to a 100mL four-necked flask equipped with an electric stirrer, a spherical condenser, and a thermometer, and swell for 12h. Add 4mL of triethylamine, start stirring, heat, and raise the temperature to 80°C for 24h. After the reaction, the resin is placed in a glass ion exchange column, rinsed with ethanol until no oil flows out, and rinsed with a large amount of deionized water to obtain a chlorine-type strong and weak base anion exchange resin. The exchange amount of strong base and weak base is shown in Table 1, and the structural formula is as follows:

Embodiment 3

[0032] Add 15g of macroporous chloromethylated polystyrene resin to a 250mL four-necked flask equipped with a stirrer, a spherical condenser, and a thermometer, swell with 100mL of absolute ethanol for 8 hours, and then add 20mL of 4 times the amount (molar ratio) of ethanolamine , heated to 50°C, and reacted for 18h. Pour out liquids such as ethanol, add 100mL of 1mol / L sodium hydroxide solution, stir at room temperature for 2h, pour out the liquid, wash with water until neutral, and reflux extract with absolute ethanol for 24h. Vacuum dry. The obtained resin III has the following structural formula.

[0033] Add 5.0g of resin III to a 100mL four-necked flask equipped with a stirrer, a spherical condenser, and a thermometer, add 30mL of benzene dried over magnesium sulfate for 48 hours, and 5mL of pyridine dried over anhydrous potassium carbonate, and swell for 6 hours under ice-water bath conditions. 12mL of thionyl chloride was added dropwise, and the addition was complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com